Method for improving straw methane yield and reducing methane liquid by methane liquid circulation

A biogas slurry and biogas technology, applied in fermentation, waste fuel, etc., can solve environmental pollution and other problems, achieve environmental friendliness, save experimental drug costs and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

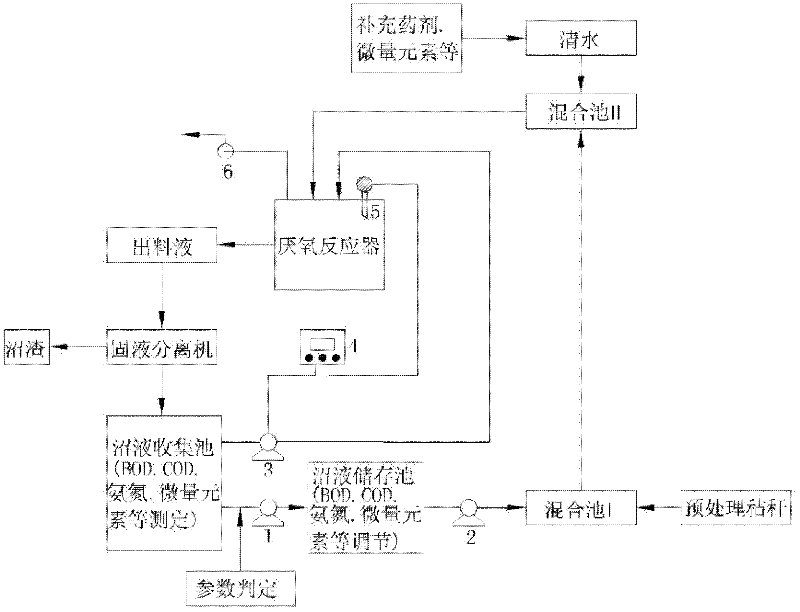

Method used

Image

Examples

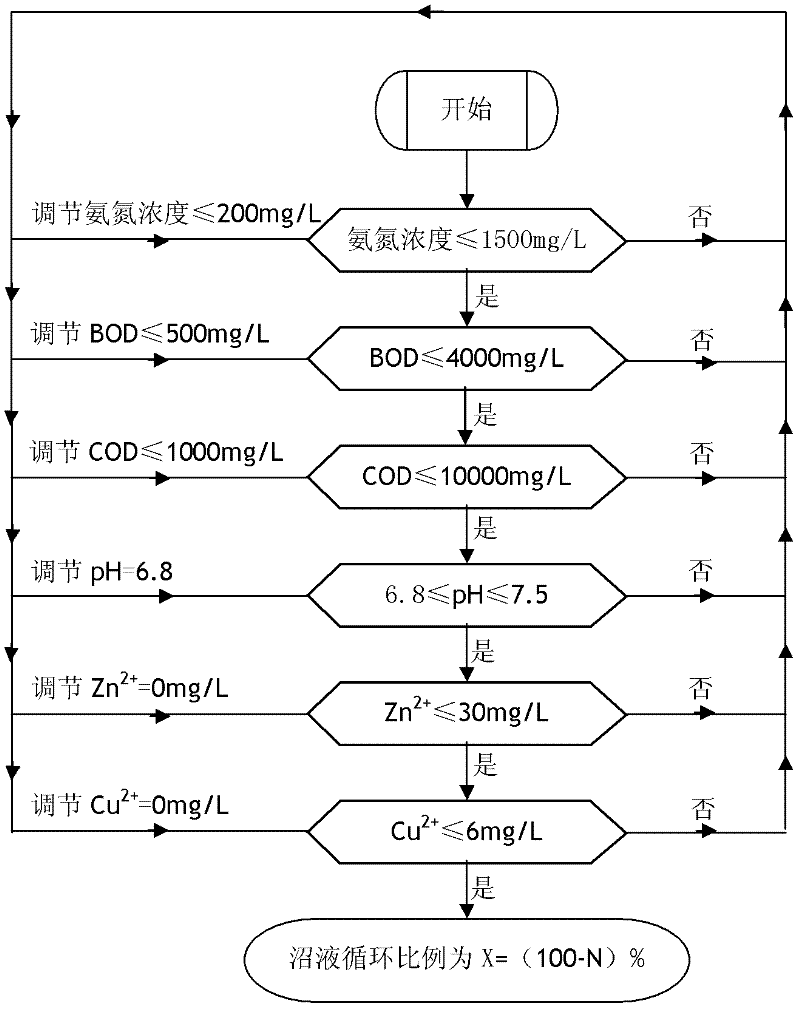

Embodiment 1

[0035]The effective volume of the anaerobic digestion reactor in the experimental device used in this example is 8L, the anaerobic fermentation material is wheat straw, and the load is 65gTS / L (TS is the dry weight of wheat straw). In the continuous anaerobic fermentation experiment with stable operation, wheat straw with a dry weight of 12.8 g was chemically pretreated (the amount of NaOH powder and water added were 2% and 600% of the dry weight of the wheat straw, respectively) and then sent into the mixing tank I. . Measure the biogas slurry parameters in the collection pond, the ammonia nitrogen concentration is 10mg / L, and the auxiliary parameters are (BOD=1000mg / L; COD=4000mg / L; Zn 2+ =5mg / L; Cu 2+ =1mg / L; pH=7.2), since the ammonia nitrogen concentration and auxiliary parameters are not beyond the specified range, then the ammonia nitrogen concentration C=10mg / L, the biogas slurry circulation ratio is determined to be 100%. The 70mL biogas slurry is sent from the coll...

Embodiment 2

[0037] The effective volume of the anaerobic digestion reactor in the experimental device used in this example is 8L, the anaerobic fermentation material is wheat straw, and the load is 65gTS / L (TS is the dry weight of wheat straw). In the continuous anaerobic fermentation experiment with stable operation, wheat straw with a dry weight of 12.8 g was chemically pretreated (the amount of NaOH powder and water added were 2% and 600% of the dry weight of the wheat straw, respectively) and then sent into the mixing tank I. . Measure the biogas slurry parameters in the collection pond, the ammonia nitrogen concentration is 380mg / L, and the auxiliary parameters are (BOD=1500mg / L; COD=5000mg / L; Zn 2+ =10mg / L; Cu 2+ =2mg / L; pH=7.25), since the ammonia nitrogen concentration and auxiliary parameters do not exceed the specified range, the ammonia nitrogen concentration C=380mg / L determines that the biogas slurry circulation ratio is 75%. The 52.5mL biogas slurry is sent from the collec...

Embodiment 3

[0039] The effective volume of the anaerobic digestion reactor in the experimental device used in this example is 8L, the anaerobic fermentation material is rice straw, and the load is 65gTS / L (TS is the dry weight of rice straw). In the continuous anaerobic fermentation experiment with stable operation, rice straw with a dry weight of 12.8 g was chemically pretreated (the amount of NaOH powder and water added were 2% and 600% of the dry weight of the rice straw, respectively) and then sent into the mixing tank I . Measure the biogas slurry parameters in the collection pond, the ammonia nitrogen concentration is 760mg / L, and the auxiliary parameters are (BOD=2000mg / L; COD=6000mg / L; Zn 2+ =15mg / L; Cu 2+ =3mg / L; pH=7.3), since the ammonia nitrogen concentration and auxiliary parameters do not exceed the specified range, the biogas slurry circulation ratio is determined to be 50% based on the ammonia nitrogen concentration C=760mg / L. The 35mL biogas slurry is sent from the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com