Activity-deep-blue LA and preparation process thereof

The technology of a compound and a wetting agent, which can be used as a compound that can be used as an active deep blue LA low-alkali dye and its preparation field, can solve problems such as environmental pollution and inability to achieve, and achieve good cleaning performance, high directness, and excellent cloth surface cleaning. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

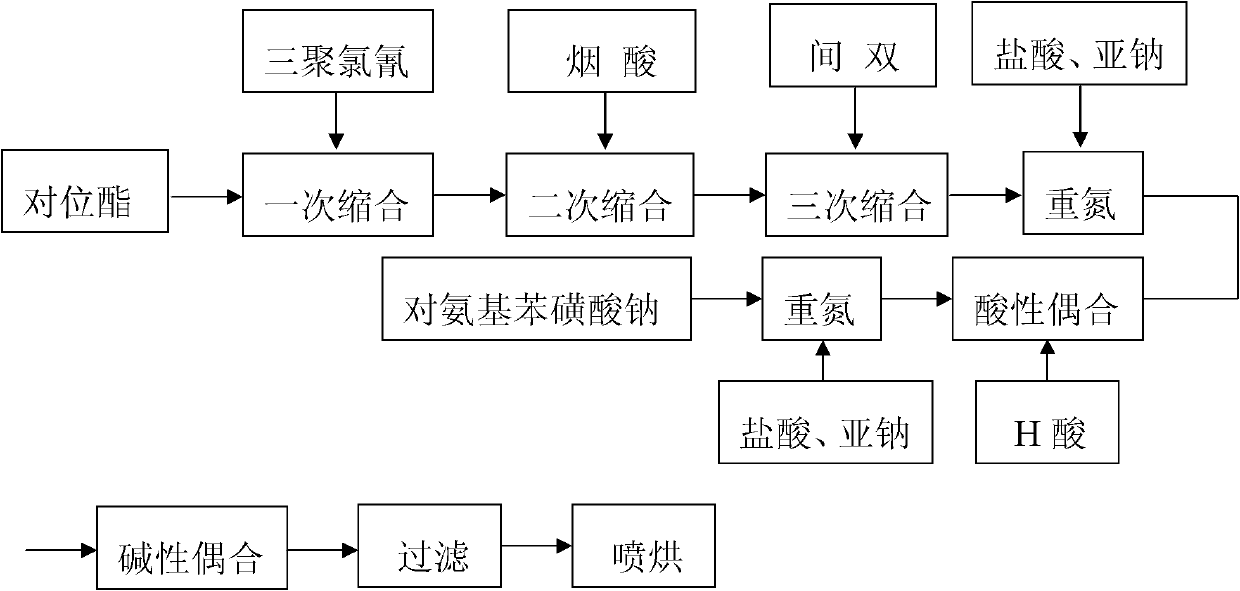

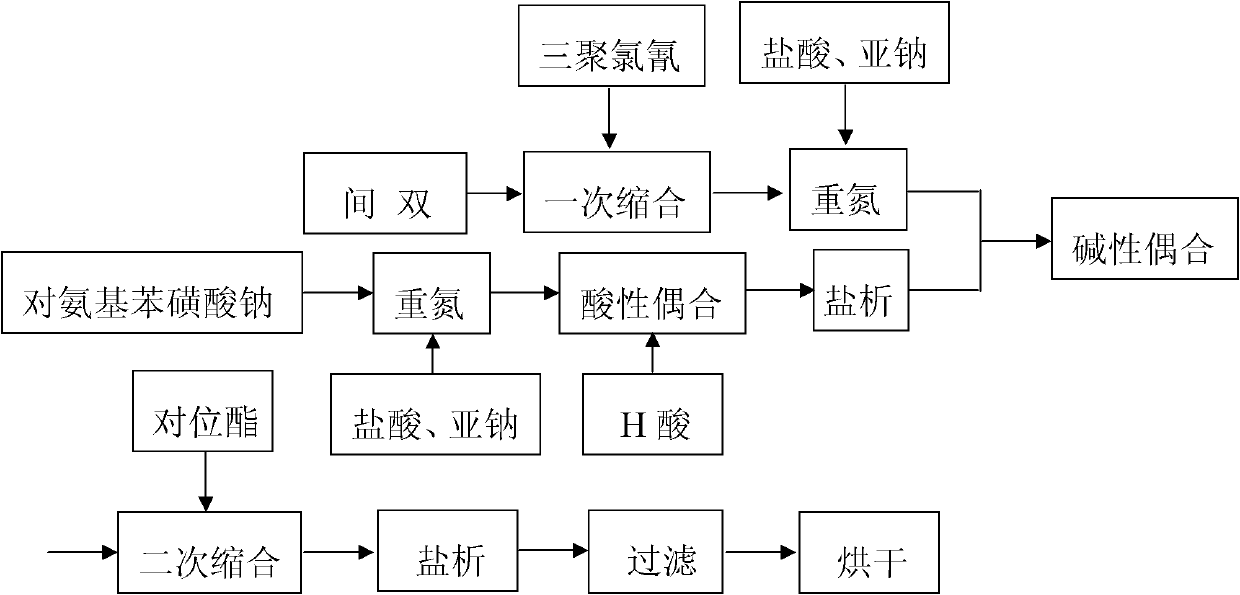

Method used

Image

Examples

Embodiment 1

[0074] 1. Nitrogen and acid couple reaction

[0075] In a 1000ml beaker, add an appropriate amount of 45 parts (1 part is 1g, the same below) of ice water, 17.3 parts of sodium p-aminobenzenesulfonate and 0.2 parts of accelerator for beating for 1 hour, add 20 parts of ice to cool down to 5 ° C, add 30.4 Part of hydrochloric acid and 7.1 parts of sodium nitrite for diazonium reaction, control the temperature at 0-10°C for 1 hour, and use a small amount of sulfamic acid to eliminate the slight excess of nitrous acid.

[0076] Add 341 parts of 10% H acid solution to the diazonium salt under stirring, control the temperature to less than 5°C, add time for 1.5 hours, control the temperature at 5°C to react for 20 hours until the diazonium salt disappears, use 10% soda water to adjust PH=6.5, dissolve the alkali couple.

[0077] 2. Condensation reaction

[0078] In a 1000ml flask, add 50 parts by weight of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, add 29....

Embodiment 2

[0087] 1. Nitrogen and acid couple reaction

[0088] In a 1000ml beaker, add an appropriate amount of 45 parts of ice water, 17.6 parts of sodium p-aminobenzenesulfonate and 0.2 parts of accelerator for beating for 1 hour, add 20 parts of ice to cool down to 5 ° C, add 30.4 parts of hydrochloric acid and 7.3 parts of sodium nitrite to carry out For diazo reaction, control the temperature at 5°C for 1 hour, and use a small amount of sulfamic acid to eliminate the slight excess of nitrous acid.

[0089] Add 340 parts of 10% H acid solution to the diazonium salt under stirring, control the temperature to less than 5°C, and add for 2 hours. After the addition, control the temperature at 5°C and react for 20 hours until the diazonium salt disappears. 10% soda water to adjust PH=6.5, dissolve the alkali couple.

[0090] 2. Condensation reaction

[0091] In a 1000ml flask, add 50 parts by weight of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, add 29.2 parts of...

Embodiment 3

[0097] 1. Nitrogen and acid couple reaction

[0098] In a 1000ml beaker, add an appropriate amount of 45 parts of ice water, 18.1 parts of sodium p-aminobenzenesulfonate and 0.2 parts of accelerator for beating for 1 hour, add 20 parts of ice to cool down to 5 °C, add 30.4 parts of hydrochloric acid and 7.5 parts of sodium nitrite for For diazonium reaction, control the temperature at 0-10°C for 1 hour, and use a small amount of sulfamic acid to eliminate the slight excess of nitrous acid.

[0099] Under stirring, add 339 parts of 10% H acid solution into the diazonium salt in a trickle, control the temperature to be less than 5°C, and add for 2 hours. After the addition, control the temperature at 5°C and react for 20 hours until the diazonium salt disappears. 10% soda water to adjust PH=6.5, dissolve the alkali couple.

[0100] 2. Condensation reaction

[0101] In a 1000ml flask, add 50 parts by weight of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com