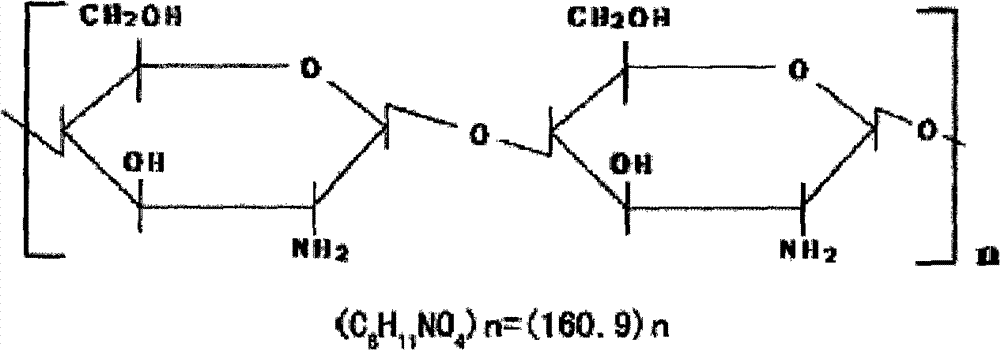

Method for dyeing chitosan fabric

A dyeing method, chitosan technology, applied in the field of dyeing and finishing, can solve the problems of poor level dyeing, prone to color blooms, etc., and achieve the effects of less content loss, increased uniformity, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A chitosan fiber blended fabric, woven from chitosan 9.7% / Newdale 56.9% / combed cotton 28.4% blended yarn and Lycra 5% (both by weight), in a jet dyeing machine , the method for dyeing it includes the following steps:

[0040] 1) Scouring process: inject 300 liters of industrial soft water into the dyeing machine, first add scouring agent DXA-150450g, softener 300g, defoamer DM-8301260g, then add 450g of 30wt% sodium hydroxide solution to make the liquid in the dyeing machine The pH value of the chitosan fabric is 10.8-11.5, put 20000g of chitosan fabric into the dyeing machine for scouring, circulate for 10 minutes, then heat up to 90 ℃, keep warm for 50 minutes and then cool down, and the temperature drops below 60 ℃ to discharge the liquid in the dyeing machine , and then washed with water until the pH of the solution is 8.3 to 7.2;

[0041] The washing process includes the first washing, 300 liters of water is injected into the dyeing machine, the washing temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com