Steel slag asphalt graded crushed rock mixture

A technology for grading crushed stone and steel slag asphalt, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of lack of asphalt grading crushed stone mixture, etc. And the effect of low maintenance cost and improved carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

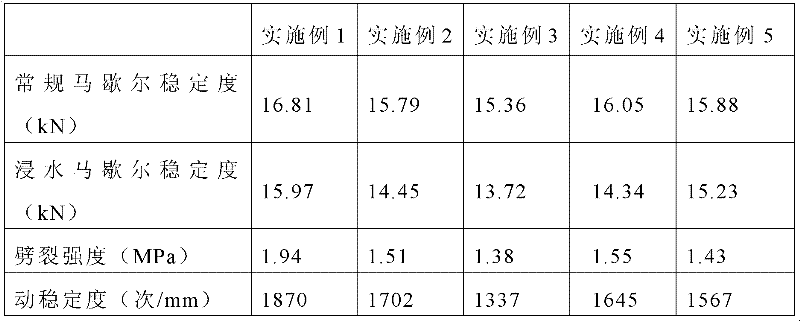

Examples

Embodiment 1

[0017] A steel slag asphalt graded crushed stone mixture, the weight percentage content of each component is: aggregate particles account for 92%, 70# heavy traffic asphalt accounts for 5%, limestone powder accounts for 3%, and the aggregate is 31.5mm≥ Steel slags with particle size > 19mm, 19≥ particle size > 9.5mm, 9.5≥ particle size > 4.75mm, 4.75≥ particle size > 0mm are composed of steel slag with four particle sizes, and the weight percentages of the four particle sizes in the aggregate are 21%, 22%, 21% and 36%, the steel slag is obtained from the converter slag of Wuhan Iron and Steel Company after three years of aging under natural conditions, and the apparent relative density of the selected steel slag is between 3.300 and 3.400g / cm 3 The content of free calcium oxide in steel slag is below 1.5%, the volume expansion rate of steel slag soaked in hot water at 60°C for 120 hours is not more than 2%; the apparent relative density of the selected limestone is 2.600-2.800g...

Embodiment 2

[0019] A steel slag asphalt graded crushed stone mixture, the weight percent content of each component is: aggregate particles account for 90%, asphalt accounts for 6%, limestone powder accounts for 4%, the aggregate is 31.5mm ≥ particle size > 19mm, 19 ≥ particle size > 9.5mm, 9.5 ≥ particle size > 4.75mm steel slag particles and 4.75 ≥ particle size > 0mm limestone particles, the weight percentages of the four particle gradations in the aggregate are 22% and 24% in turn , 22% and 32%, of which the steel slag is obtained from the converter slag of Wuhan Iron and Steel Company after three years of aging under natural conditions, and the apparent relative density of the selected steel slag is between 3.300 and 3.400g / cm 3 The content of free calcium oxide in steel slag is below 1.3%, the volume expansion rate of steel slag soaked in hot water at 60°C for 120 hours is not more than 2%; the apparent relative density of the selected limestone is 2.600-2.700g / cm 3 Among them, the p...

Embodiment 3

[0021] A steel slag asphalt graded crushed stone mixture, the weight percentage content of each component is: aggregate particles account for 93%, asphalt accounts for 4%, limestone powder accounts for 3%, the aggregate is 31.5mm≥grain size>19mm, 19≥grain size>9.5mm two kinds of steel slag particles and 9.5≥grain size>4.75mm, 4.75≥grain size>0mm two grades of limestone particles, the weight percentage of the four kinds of particle size in the aggregate is 24 %, 20%, 20% and 36%, the apparent relative density of the selected steel slag is 3.300~3.400g / cm 3 The content of free calcium oxide in steel slag is below 1.2%, the volume expansion rate of steel slag soaked in hot water at 60°C for 120 hours is not more than 2%; the apparent relative density of the selected limestone is 2.700-2.800g / cm 3 Among them, the particle size distribution of limestone ore powder used is: 0.6mm pass rate is 100%, 0.15mm pass rate is 95-100%, and 0.075mm pass rate is 90-100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com