Method for preparing sodium sulfate and magnesium nitride compound fertilizer by processing astrakhanite

A technology of leonite and sodium sulfate, applied in chemical instruments and methods, alkali metal sulfite/sulfite, fertilization devices, etc., can solve problems such as difficulty in processing and separation of leonite, and achieve overcoming the difficulty of separation The effect of large, mild reaction conditions and large elastic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

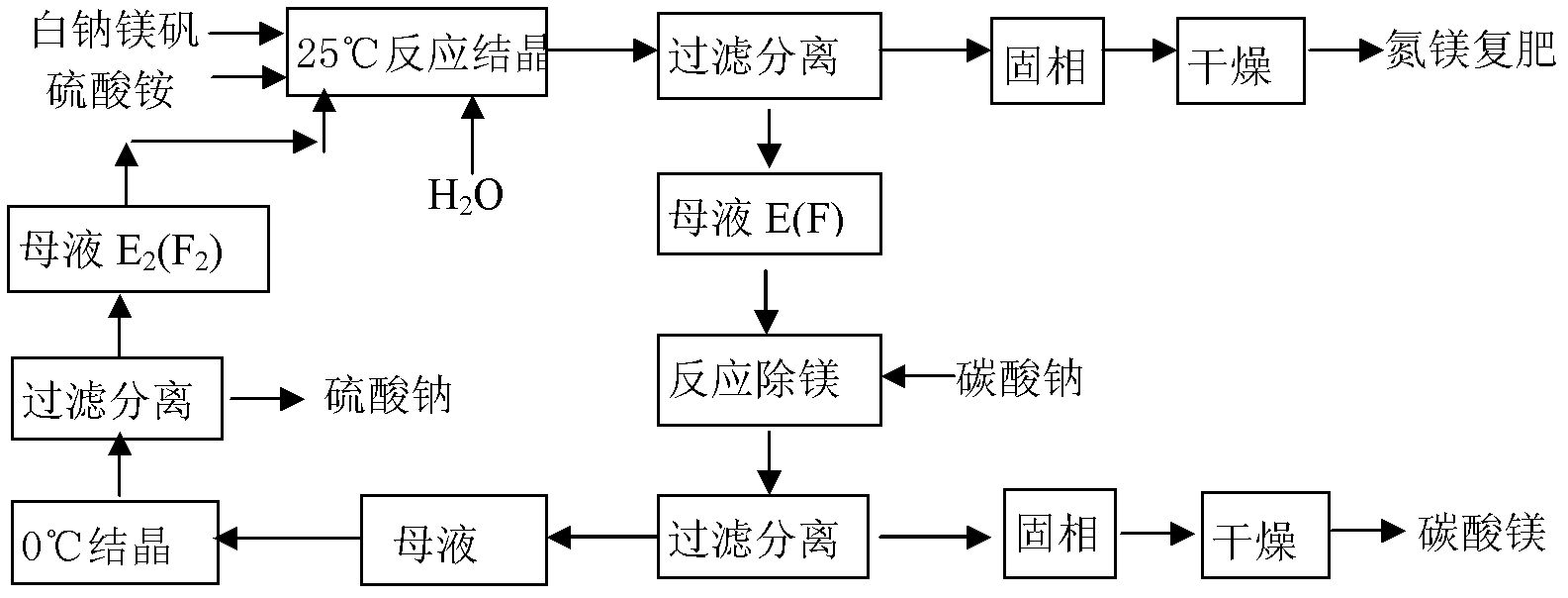

[0035] Example 1 (process route sees figure 1 )

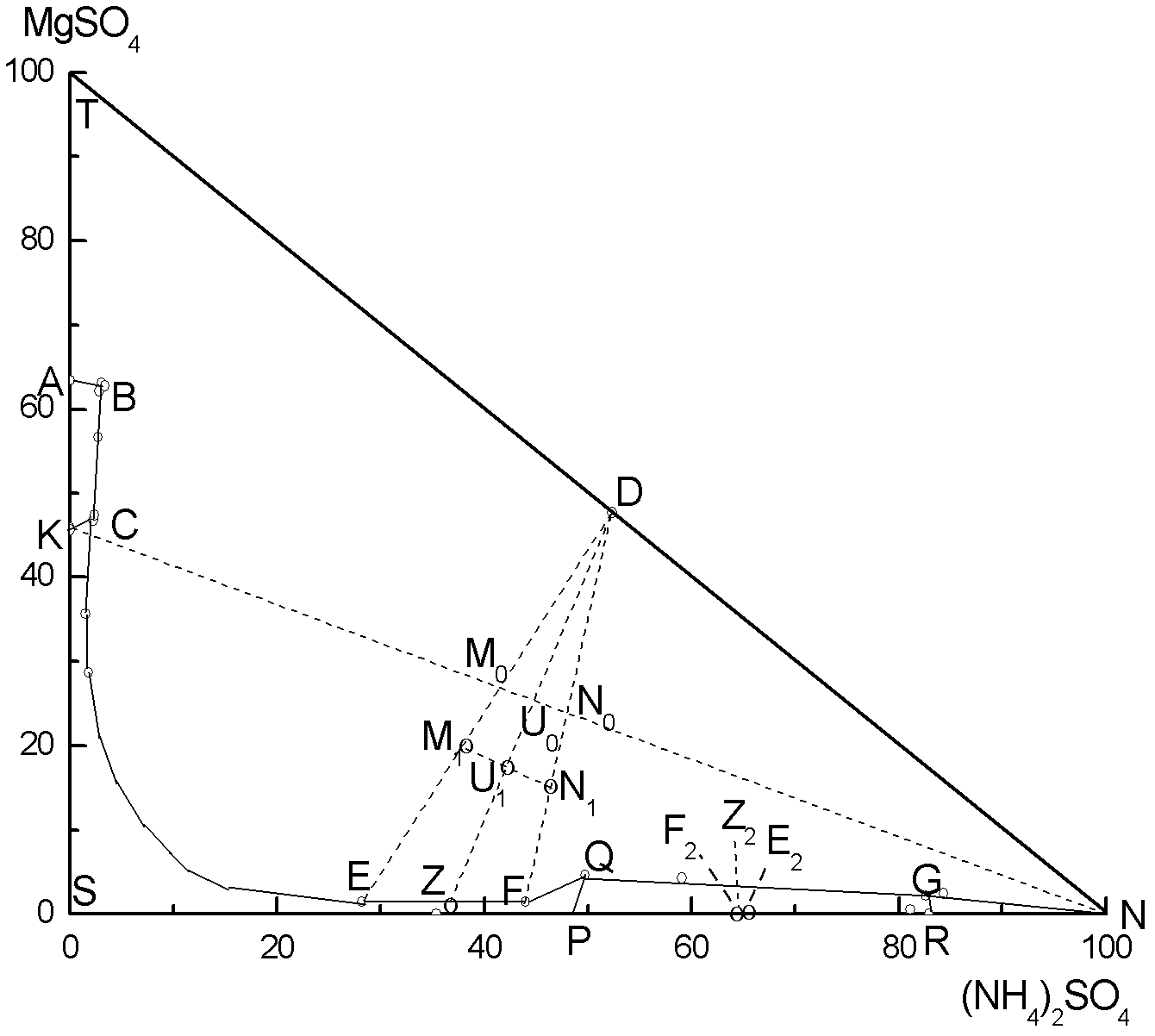

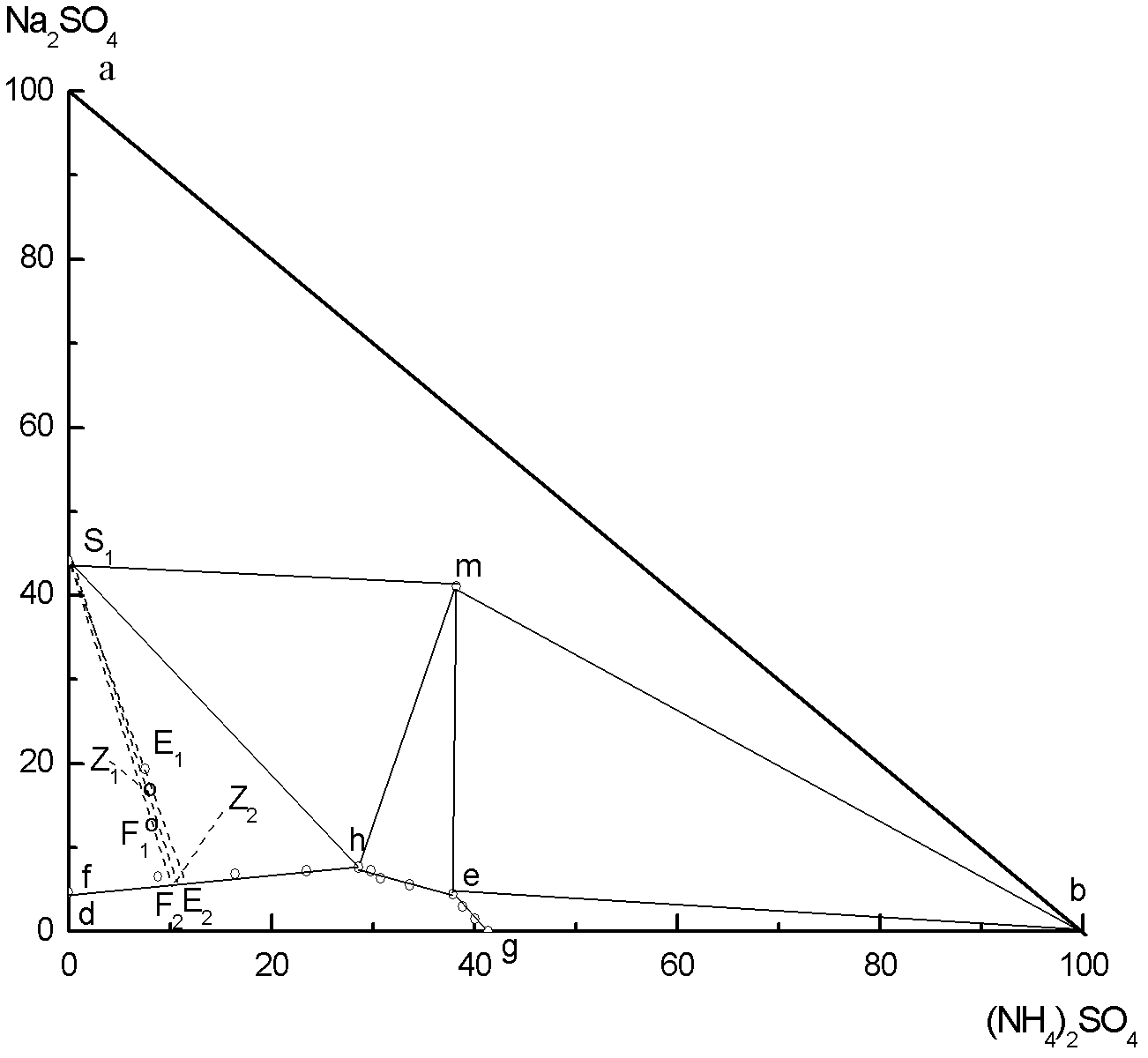

[0036] (1) 100g of kabeinite (MgSO 4 ·Na 2 SO 44H 2 O), the ammonium sulfate of 55.65g and the water of 176.38g are mixed as system composition M 0 , added to a 500ml three-necked flask, mechanically stirred and reacted in a 25°C constant temperature tank, and after 120min, nitrogen-magnesium compound fertilizer (MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 (0) will crystallize out, and after centrifuging and drying at 80°C in a centrifuge, 105.1g of the nitrogen-magnesium compound fertilizer product can be obtained. The resulting mother liquor is E with a total of 226.7g, and the mother liquor E is Na at 25°C. 2 SO 4 -MgSO 4 -(NH 4 ) 2 SO 4 -H 2 O system phase diagram of MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and Na 2 SO 4 10H 2 O two solid phase common saturated line point, record E is the mother liquor mass percentage content is Na 2 SO 4 , 18.84%; MgSO 4 , 0.3896%; (NH 4 ) 2 SO 4 , 7.536%; H 2 O, 73.23%.

[0037] (2...

example 2

[0041] Example 2 (process route sees figure 1 )

[0042] (1) 100g of kabeinite (MgSO 4 ·Na 2 SO 4 4H 2 O), the ammonium sulfate of 72.46g and the water of 326.7g are mixed as system composition N 0 , added to a 1000ml three-necked flask, mechanically stirred in a constant temperature tank at 25°C for reaction, and after 120min, nitrogen-magnesium compound fertilizer (MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 (0) will crystallize out, and after the centrifuge centrifugal treatment dries, just can get nitrogen-magnesium compound fertilizer product 104.5g. The resulting mother liquor is a total of 394.7g of F, and the mother liquor F is Na at 25°C. 2 SO 4 -MgSO 4 -(NH 4 ) 2 SO 4 -H 2 O system phase diagram of MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and Na 2 SO 4 10H 2 O two solid phase co-saturation line points, the measured F mother liquor mass percentage content is Na 2 SO 4 , 10.76%; MgSO 4 , 0.2817%; (NH 4 ) 2 SO 4 , 8.654%; H 2 O, 80.30%;

[0043] (2) Add the above...

example 3

[0047] Example 3 (process route sees figure 1 )

[0048] (1) 100g of kabeinite (MgSO 4 ·Na 2 SO 4 4H 2 O), the ammonium sulfate of 63.70g and the water of 249.7g are mixed as system composition U 0 , added to a 1000ml three-necked flask, mechanically stirred in a constant temperature tank at 25°C for reaction, and after 120min, nitrogen-magnesium compound fertilizer (MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 (0) will crystallize out, and after centrifugal processing and drying in a centrifuge, 104.8g of nitrogen-magnesium compound fertilizer product can be obtained. The resulting mother liquor is Z, a total of 308.6g, and mother liquor Z is Na at 25°C. 2 SO 4 -MgSO 4 -(NH 4 ) 2 SO 4 -H 2 O system phase diagram of MgSO 4 ·(NH 4 ) 2 SO 4 ·6H 2 O and Na 2 SO 4 10H 2 O two solid phase co-saturation line points, the measured Z mother liquor mass percentage content is Na 2 SO 4 , 13.85%; MgSO 4 , 0.3242%; (NH 4 ) 2 SO 4 , 8.212%; H 2 O, 77.61%.

[0049] (2) Add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com