Active brown coal and preparation method thereof

A coal and active technology, applied in the field of active lignite and its preparation, can solve the problems of poor biological activity and high cost, and achieve the effect of developed macroporous pore structure, low cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

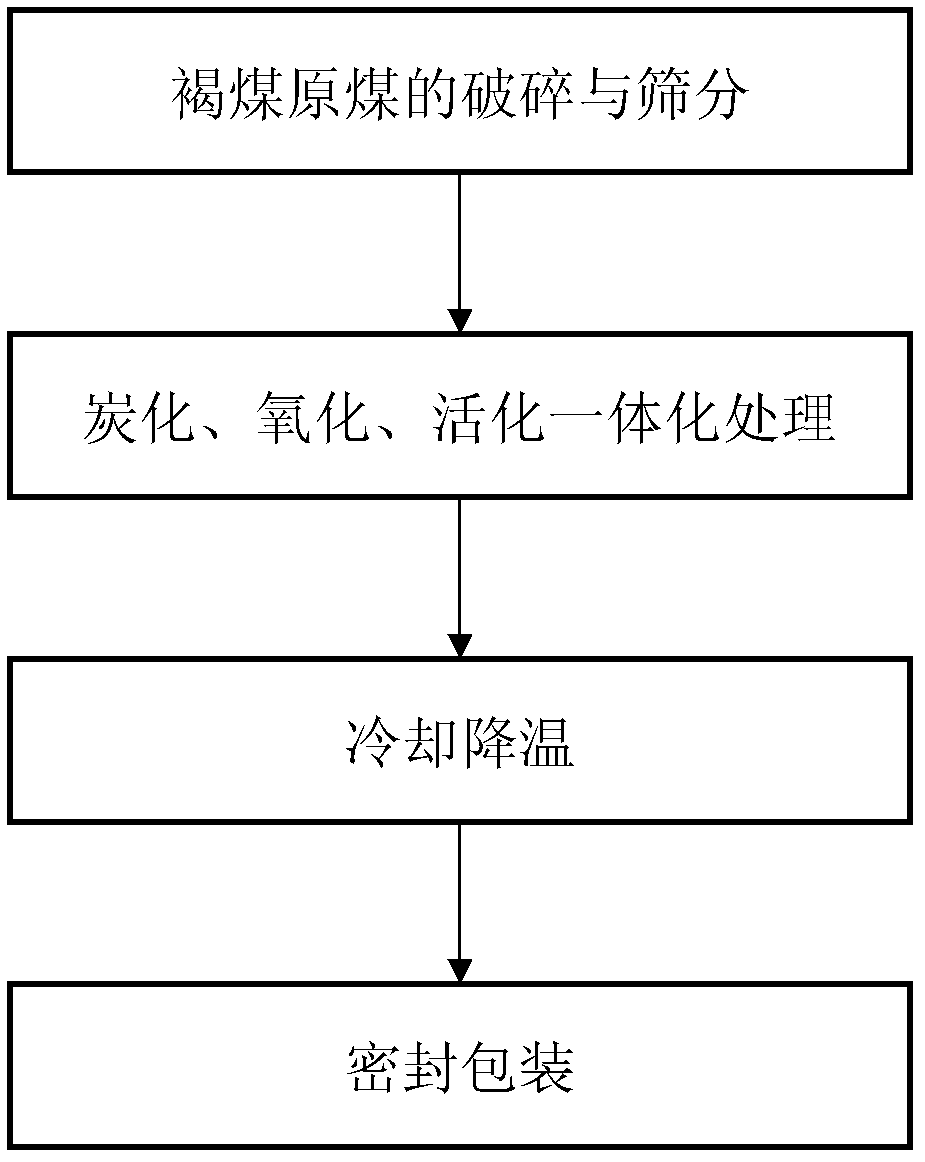

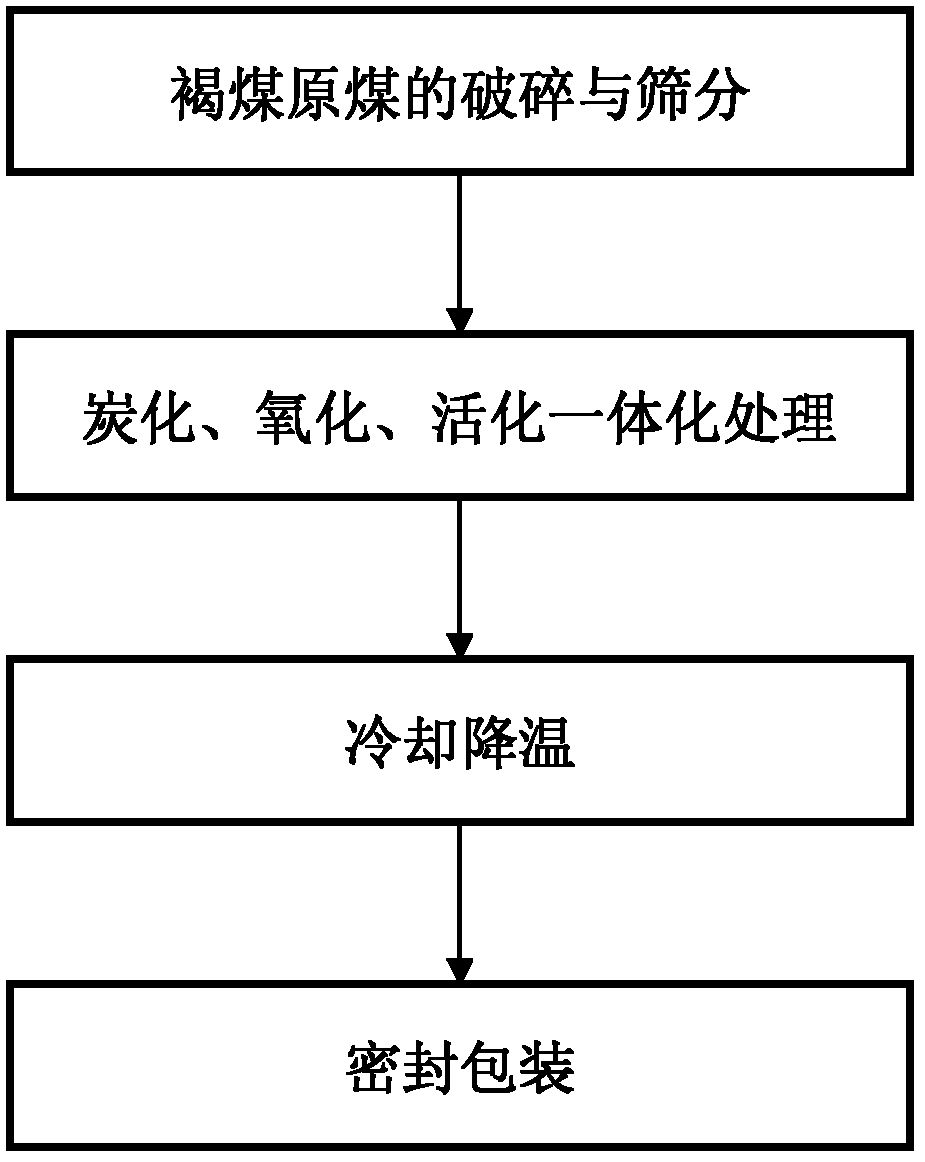

[0018] The raw material selects Zhalainuoer lignite with ash content of about 8% and moisture content of 35%. The preparation method of active lignite is as shown in the accompanying drawings, including the following steps:

[0019] Step 1: Crushing and sieving of lignite raw coal: crushing and sieving the Zhalai Nuoer lignite into wide sieving particles with a diameter of less than 50 mm;

[0020] Step 2: Integrated treatment of carbonization, oxidation, and activation: Send the crushed and screened particles into an integrated upgrading reactor for integrated treatment of carbonization, oxidation, and activation under reducing atmosphere conditions, and the integrated upgrading reactor The internal temperature is 400°C, the fluidization velocity is 2m / s, and the processing time is 10min to obtain the finished product;

[0021] Step 3: Cooling and lowering the temperature: the finished product from the integrated upgrading reactor in step 2 is anaerobically cooled to 50°C thr...

Embodiment 2

[0025] The raw material selects Yimin lignite with ash content of about 12% and moisture content of 40%. The preparation method of active lignite is as shown in the accompanying drawing, including the following steps:

[0026] Step 1: Crushing and sieving of lignite raw coal: crushing and sieving the Zhalai Nuoer lignite into wide sieving particles with a diameter of less than 50 mm;

[0027] Step 2: Integrated treatment of carbonization, oxidation, and activation: Send the crushed and screened particles into an integrated upgrading reactor for integrated treatment of carbonization, oxidation, and activation under reducing atmosphere conditions, and the integrated upgrading reactor The internal temperature is 550°C, the fluidization velocity is 3.5m / s, and the processing time is 8min to obtain the finished product;

[0028] Step 3: cooling down: the finished product from the integrated upgrading reactor in step 2 is anaerobically cooled to 40°C through the finished product coo...

Embodiment 3

[0032] The raw material is selected from Baorixile lignite with an ash content of about 8% and a water content of 31%. The preparation method of the active lignite is shown in the accompanying drawing, including the following steps:

[0033] Step 1: Crushing and sieving of lignite raw coal: crushing and sieving the Zhalai Nuoer lignite into wide sieving particles with a diameter of less than 50 mm;

[0034] Step 2: Integrated treatment of carbonization, oxidation, and activation: Send the crushed and screened particles into an integrated upgrading reactor for integrated treatment of carbonization, oxidation, and activation under reducing atmosphere conditions, and the integrated upgrading reactor The temperature inside is 700°C, the fluidization velocity is 8m / s, and the processing time is 6min to obtain the finished product;

[0035] Step 3: Cooling and cooling: the finished product from the integrated upgrading reactor in step 2 is anaerobically cooled to 35°C through the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com