Manufacturing method of plane wing-body fairing

A manufacturing method and fairing technology, which are applied in the field of aircraft wing body fairing production, can solve the problems of difficult adjustment of design results, difficult to guarantee the surface quality, difficult to control the lofting law, etc., and achieve simple and convenient modification, good surface quality and design Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, a description of preferred embodiments of the present invention will be provided in detail with reference to the accompanying drawings.

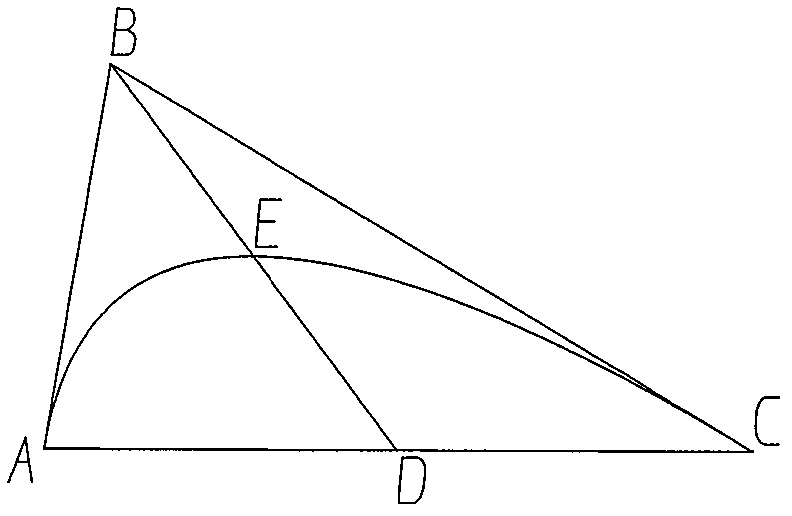

[0047] figure 1 Be according to the schematic diagram of the manufacture method of aircraft wing-body fairing of the present invention, wherein, 1 1 -l 4 The four vertical solid lines are the guide lines, the dashed lines are the tangent vectors at both ends of the quadratic curve, and the surface s is the lower boundary l 1 The stretched surface along the direction of the symmetry plane controls the tangent direction of the lower boundary during the sweeping process, and the dotted line controls the sweeping direction.

[0048] Figure 2a-2d A schematic diagram showing the principle of the method for determining the quadratic curve of the present invention. Conic algebraic expression: Ax 2 +Bxy+Cy 2 +Dx+Ey+F. =0 The geometric diagram of the quadratic curve is as follows Figure 2a As shown, among them, the quadr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com