Hydraulic assembly of electro-hydraulic switch machine

A technology of hydraulic assembly and switch machine, which is used in hydraulic equipment for operating turnouts or line interrupters, railway car body parts, railway signals, etc., can solve the problem of increased sealing difficulty, manual labor, and difficulty in coordination and synchronization. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

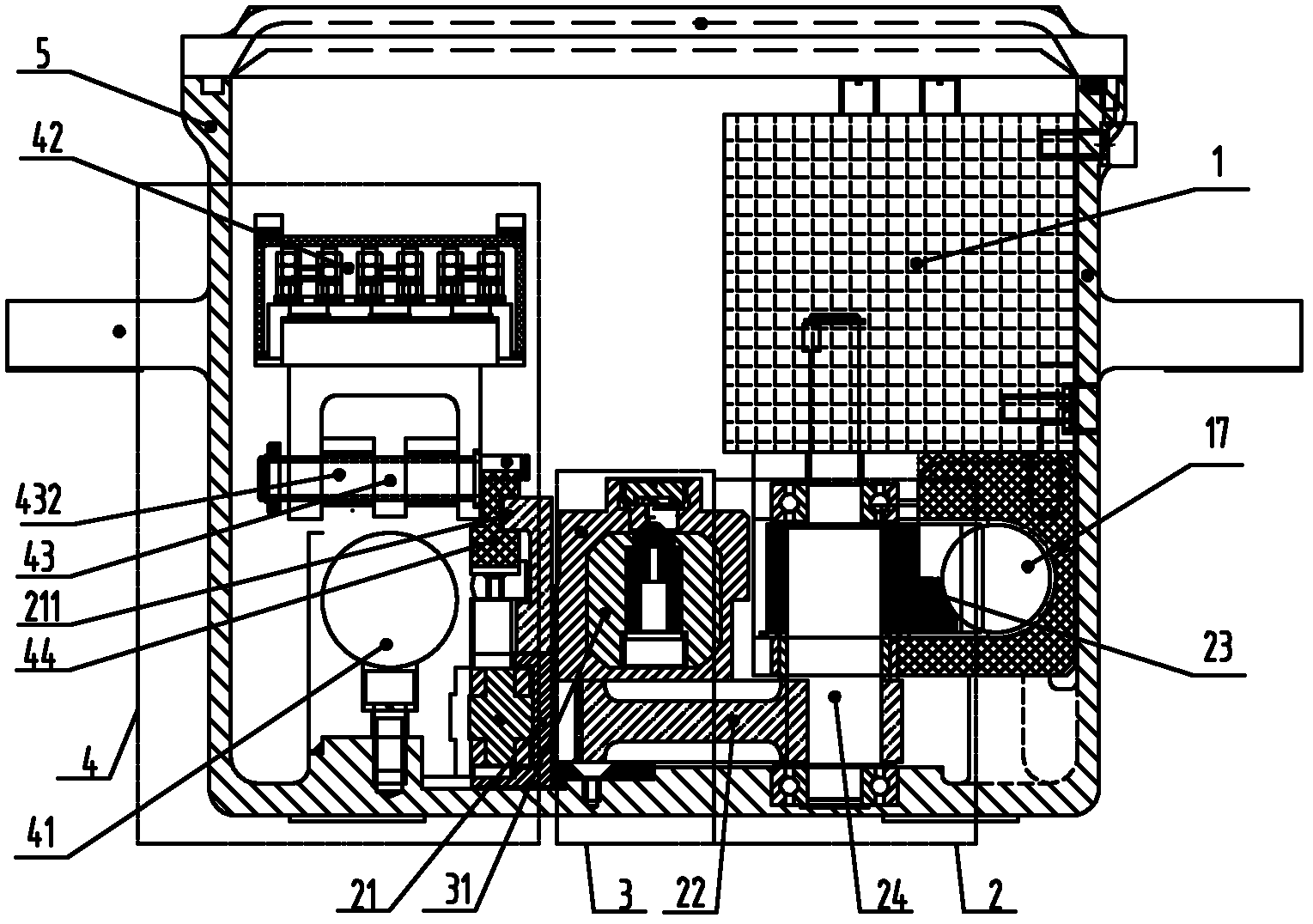

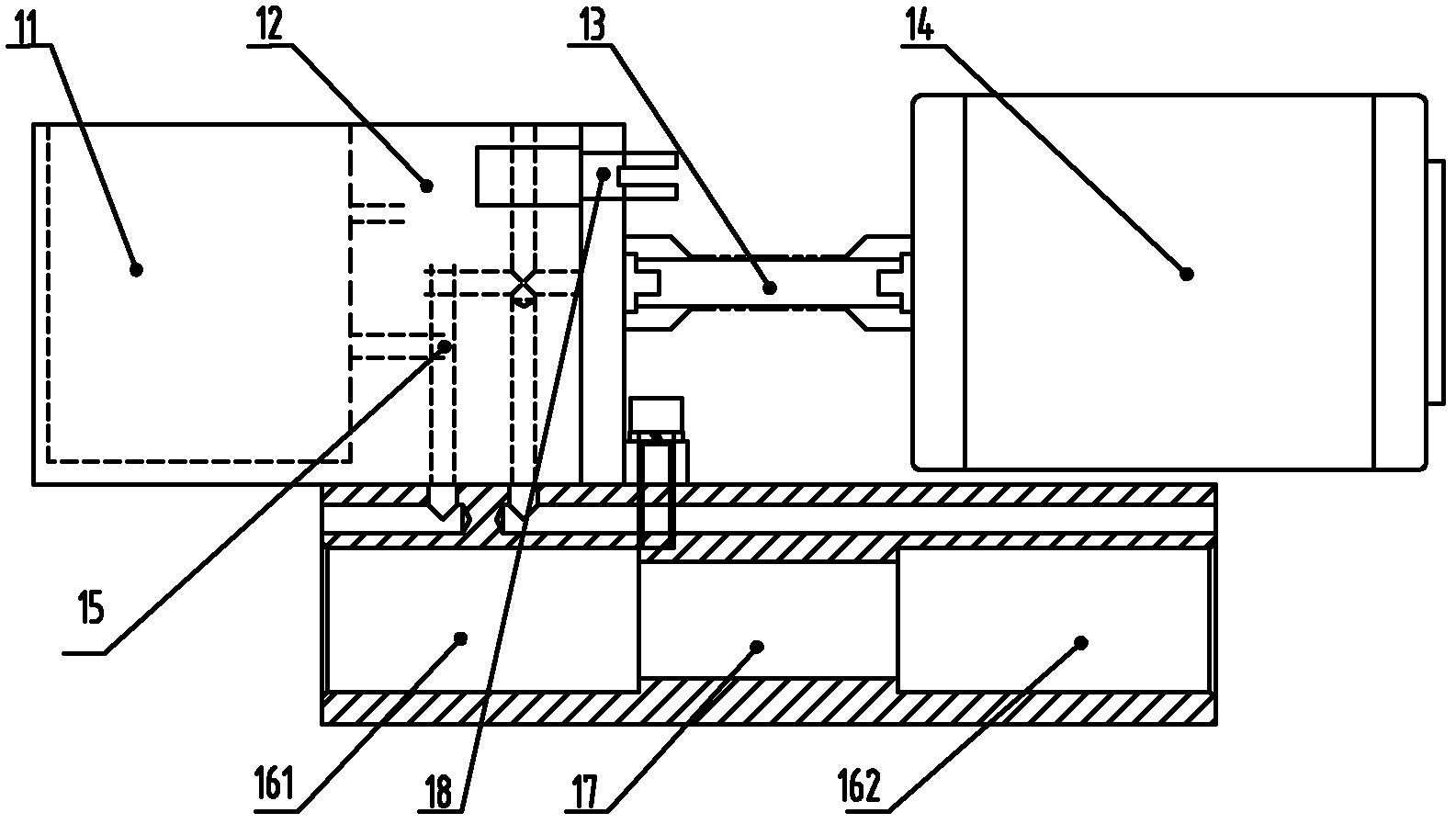

[0023] Such as figure 1 and figure 2 As shown, an electro-hydraulic switch machine is provided, including an electric motor 14, a hydraulic assembly 1, a transmission mechanism 2, a conversion locking mechanism 3 and an indication mechanism 4, which are connected to each other.

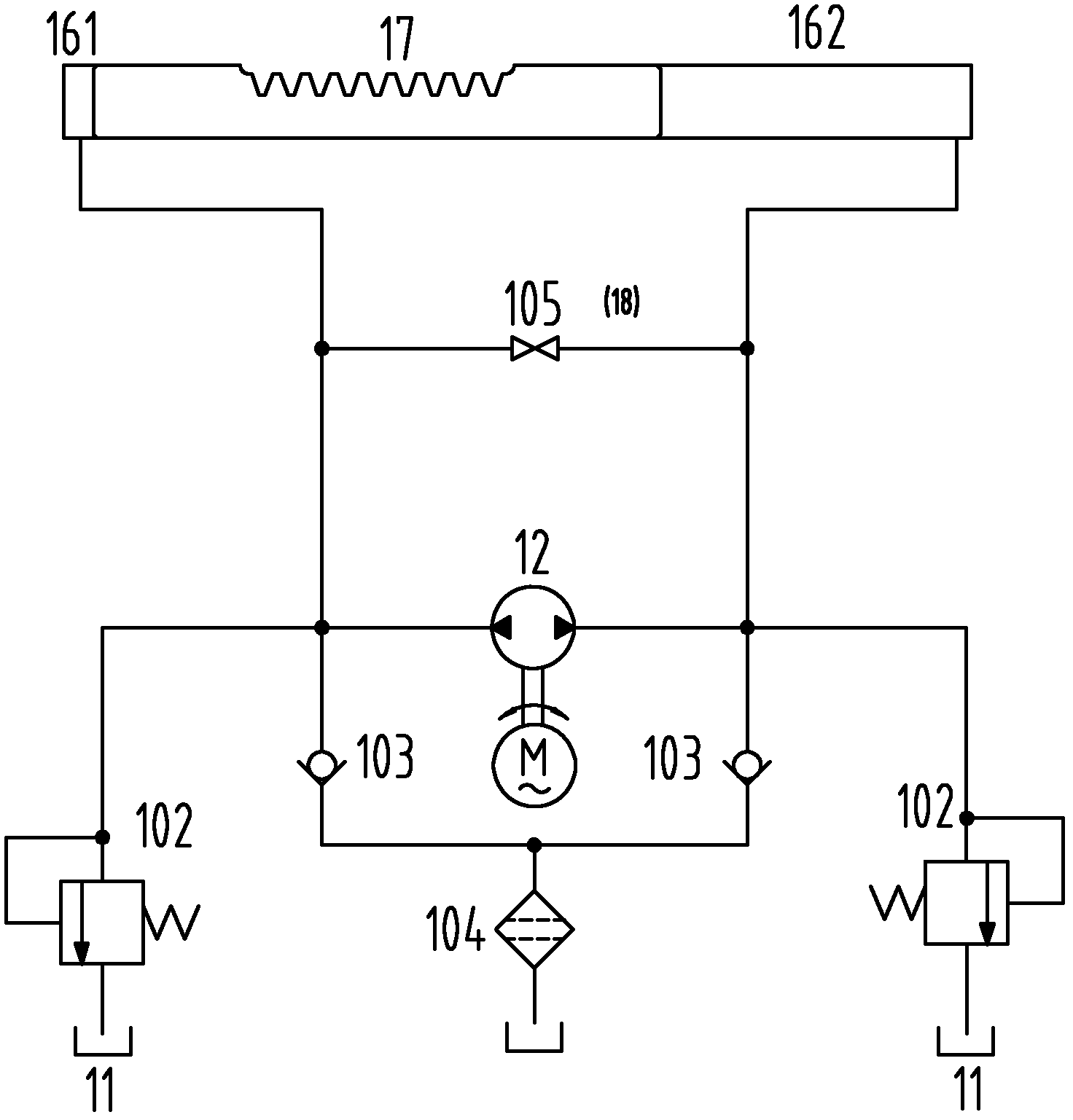

[0024] Such as figure 2 As shown, the oil cylinder 16 in the hydraulic assembly 1 is a double-acting oil cylinder, and the oil cylinder includes a left oil cylinder 161 and a right oil cylinder 162. A piston is respectively arranged on both sides of a piston rod 17 in the middle, and the two pistons are respectively placed In the two oil cylinders, the oil cylinder body is fixed and the piston moves; the three-phase AC motor 14 is connected to the oil pump through the electric motor oil pump transmission shaft 13, and the oil pump is connected to the oil tank 11 and the oil cylinder 16 through the integrated oil pipeline 15. The piston rod in the hydraulic assembly 1 is processed into a rack tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com