Pressure dynamic compensation device and continuous ink supply system using pressure dynamic compensation

A dynamic compensation and pressure technology, applied in printing and other directions, can solve problems such as print head or printer damage, head blocking, crystallization precipitation, etc., to reduce the possibility, reduce head blocking phenomenon, and solve the effect of air blocking phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

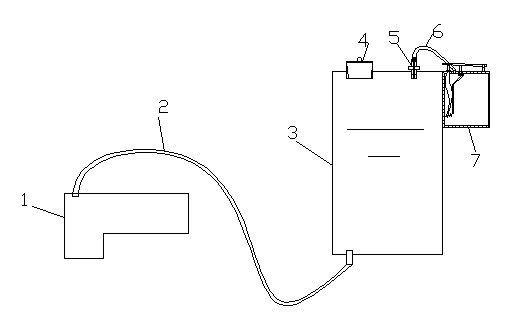

[0016] The pressure dynamic compensation continuous ink supply system includes a continuous ink supply system and a pressure dynamic compensation device. The compensation gas port 72 of the pressure dynamic compensation device communicates with the air plug 5 of the ink storage container 3 in the continuous ink supply system through the air guide tube 6 .

[0017] The continuous ink supply system includes an ink storage container 3, an ink supply conduit 2 and a printing ink cartridge 1, the ink storage container 3 communicates with the printing ink cartridge 1 through the ink supply conduit 2, and the upper end of the ink storage container 3 is provided with an ink filling port 4 and air plug 5.

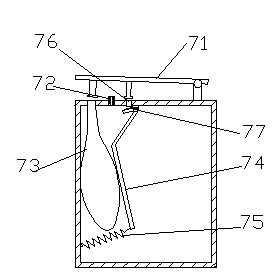

[0018] The pressure dynamic compensation device includes a pressure dynamic compensation container 7 and an elastic air bag 73, the elastic air bag 73 is built in the pressure dynamic compensation container 7, and the bag opening of the elastic air bag 7 is in sealing connection with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com