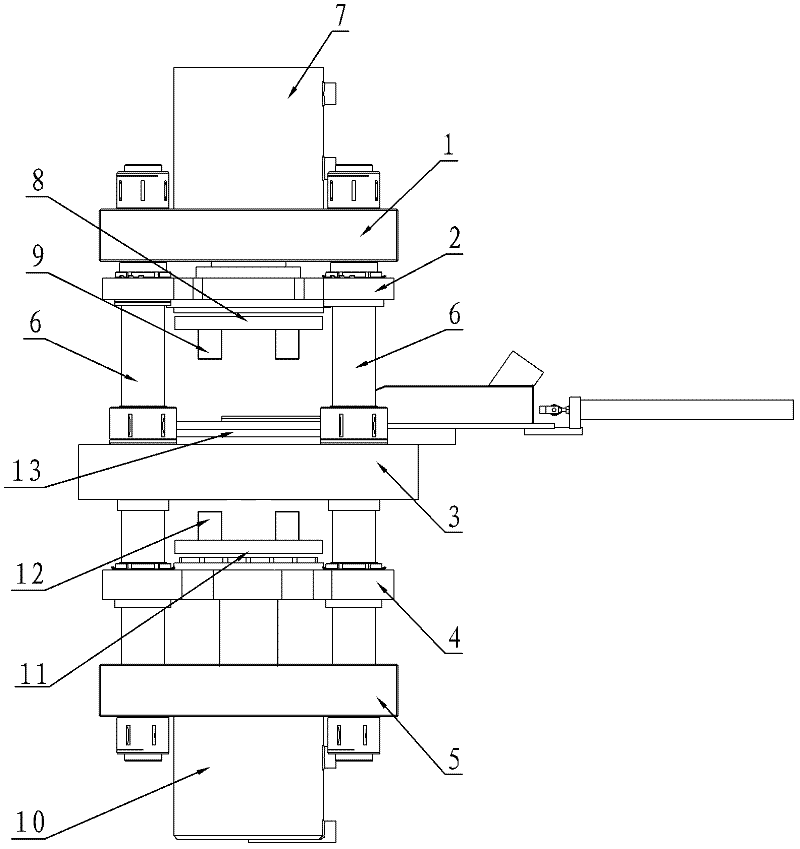

Loading depth fine adjusting device for tablet press

A fine-tuning device and technology for tablet presses, applied in the field of tablet presses, can solve the problems of great influence on adjustment accuracy, large adjustment workload, and high operation requirements, and achieve simple and easy adjustment, wide adjustment range, and ensure precise fine-tuning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

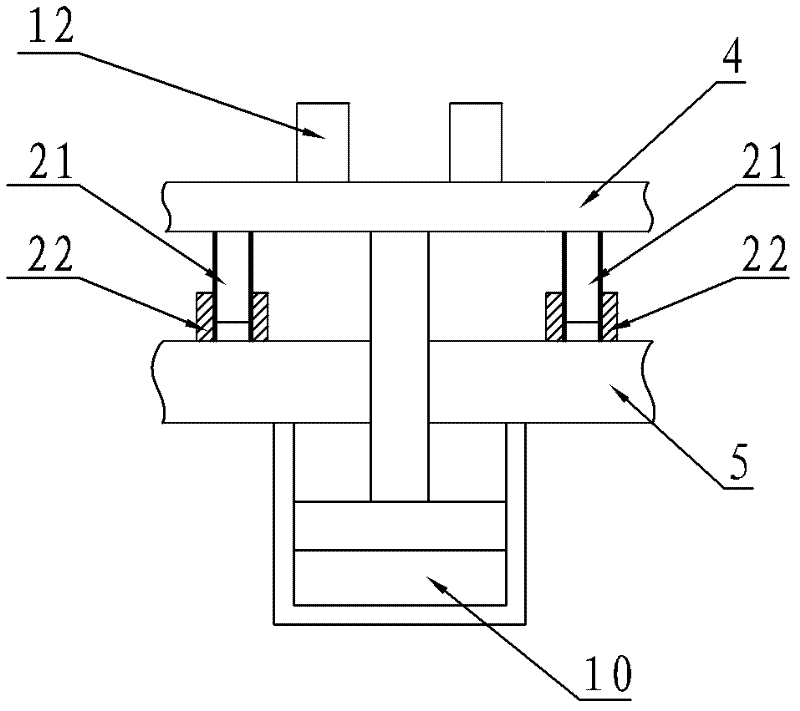

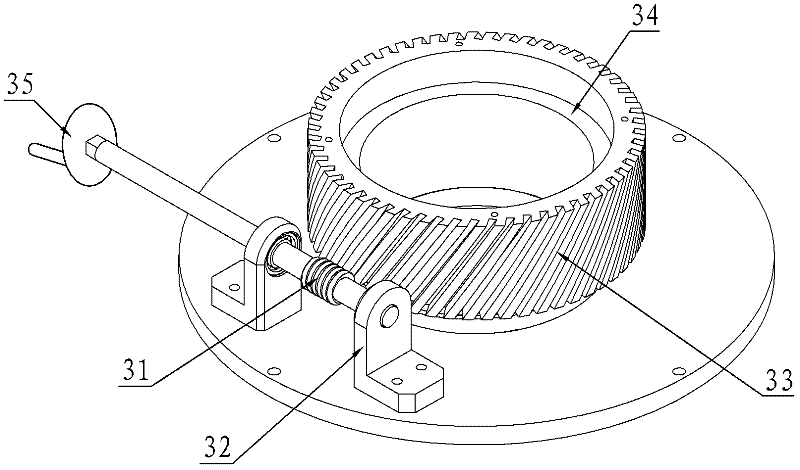

[0017] Embodiment 1: A kind of fine-tuning device for charging depth of tablet press, such as image 3 , Figure 4 As shown, it is a manually adjustable structure consisting of a worm 31, a worm bracket 32, a helical gear 33, a fixed threaded sleeve 34 and a hand wheel 35. The fixed threaded sleeve 34 is composed of a threaded sleeve and a connecting flange, and the connecting flange Set on the lower end of the threaded sleeve, the fixed threaded sleeve 34 is set on the piston rod of the lower hydraulic cylinder 10, and fixedly installed on the upper end surface of the lower fixed plate 5 through the connecting flange, on the outer circle of the fixed threaded sleeve 34 An external thread is provided, and an internal thread is provided in the inner hole of the helical gear 33. The helical gear 33 is screwed on the fixed thread sleeve 34 through the internal thread, the worm 31 is fixed on the worm bracket 32, and the worm bracket 32 is fixedly installed on the lower fixing p...

Embodiment 2

[0018] Embodiment 2: The difference from Embodiment 1 is that the drive mode of the worm 31 is different, and the worm 31 is driven by a servo motor, which facilitates the automation of fine-tuning the charging depth of the tablet press.

[0019] There are still many embodiments of the present invention. For example, on the basis of the above two embodiments, a fixed-size backing plate 36 is provided on the upper end surface of the helical gear 33, so that the fine-tuning size range can be enlarged, and the tablet press can be adapted to different thickness specifications. Compression of tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com