Dual-station pneumatic stamping machine

A punching machine, double station technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of not meeting the punching force, wasting energy, limiting the application of punching machines, etc., to achieve convenient operation, simple and compact structure, The effect of high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

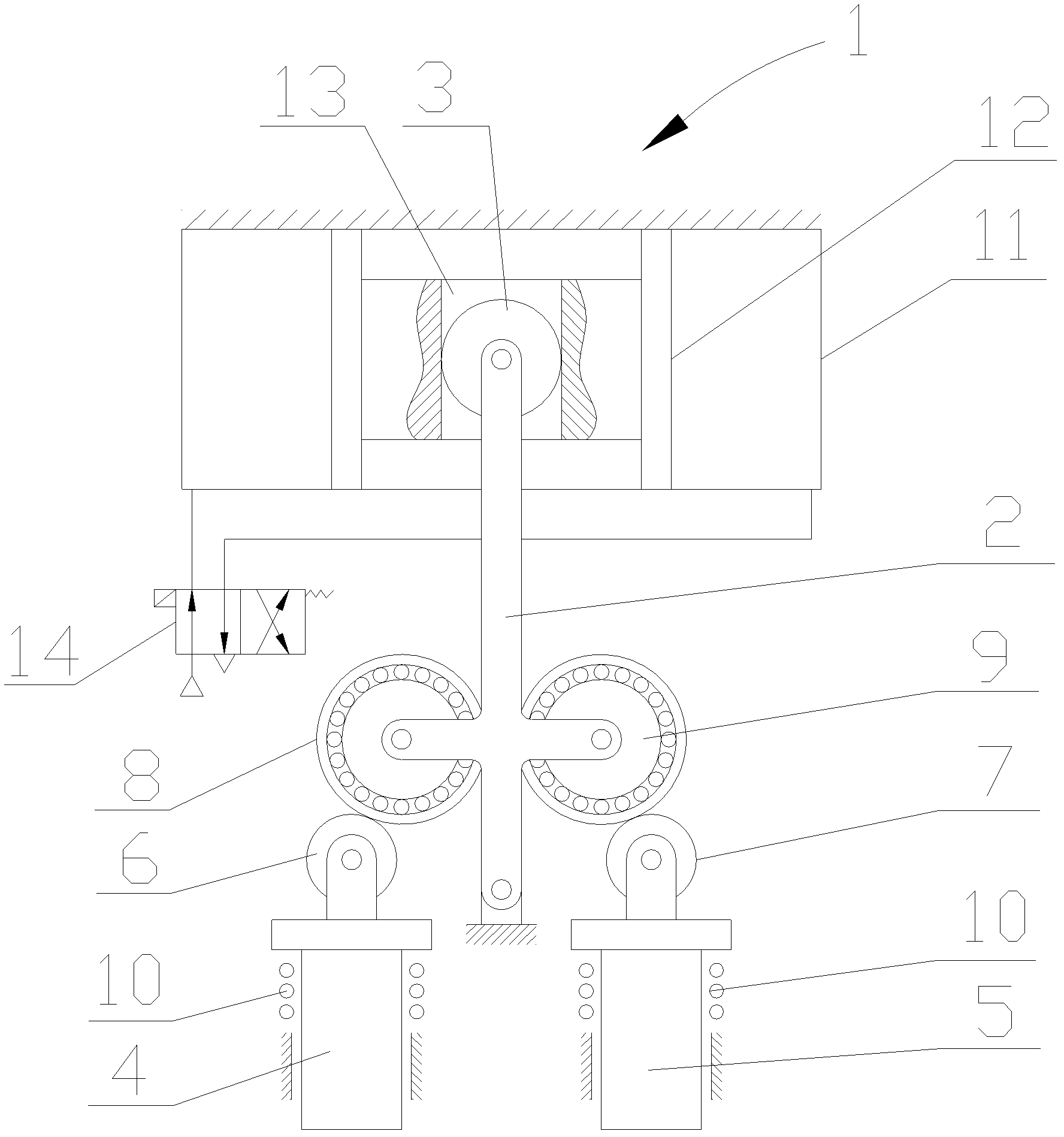

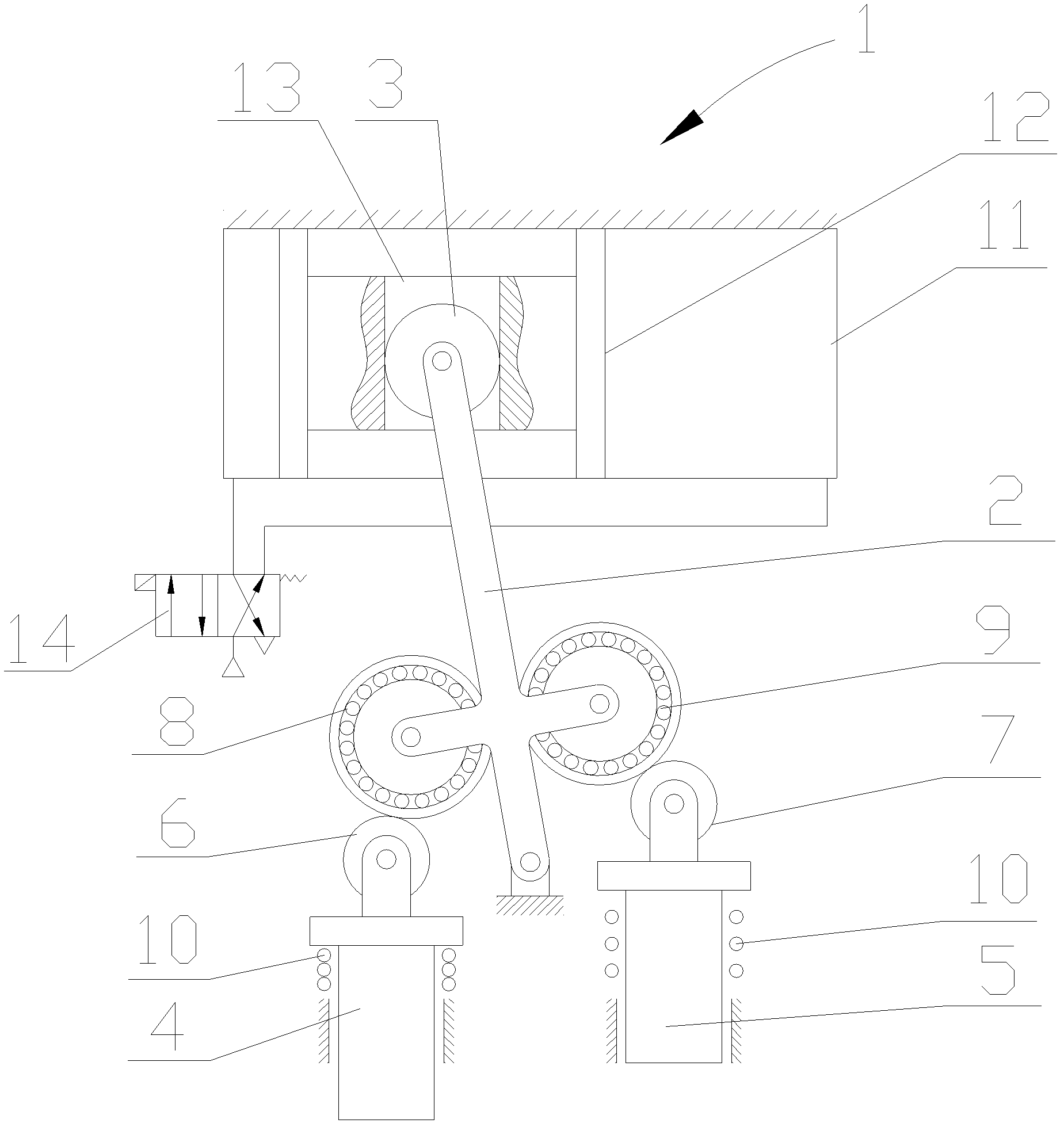

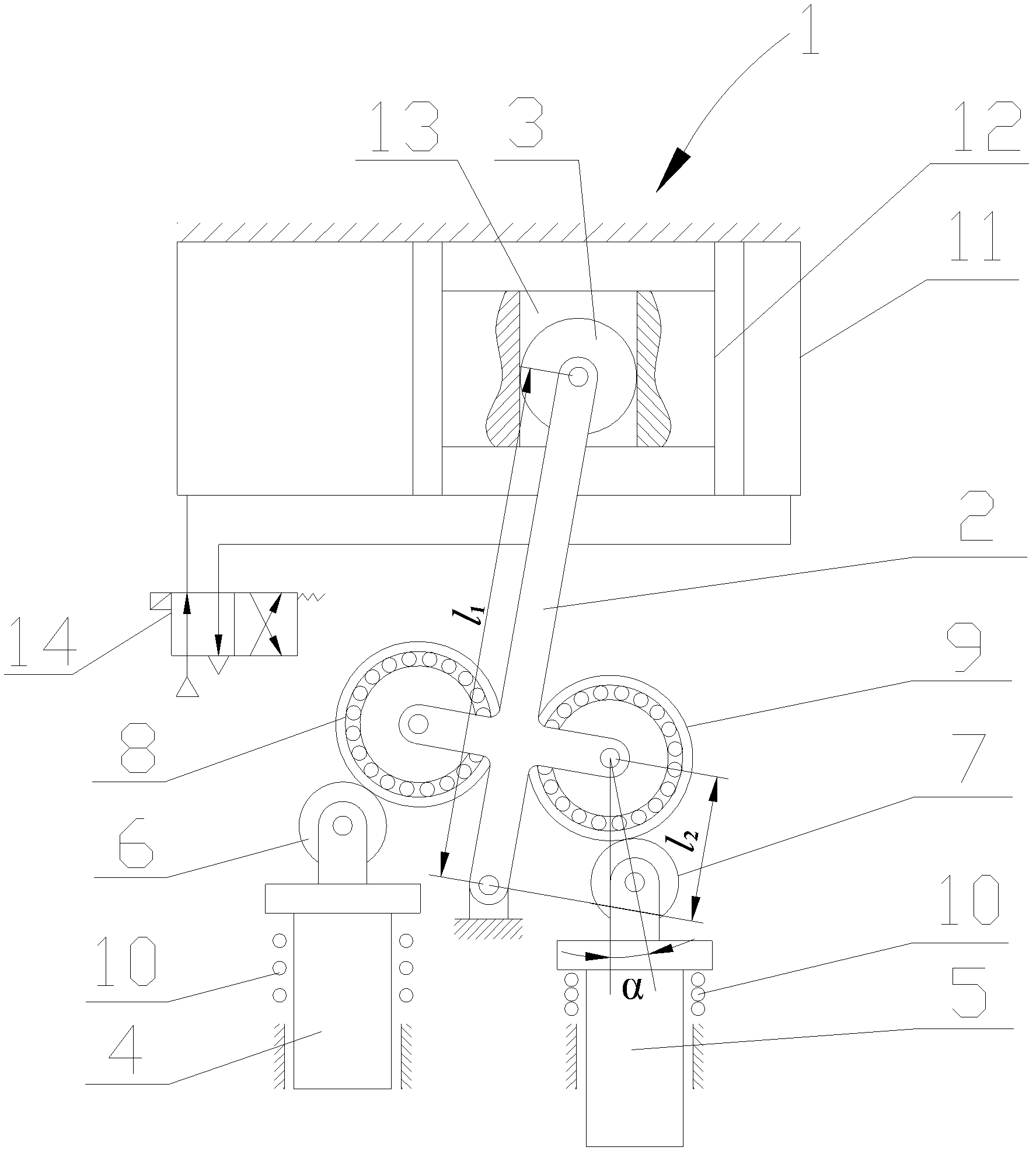

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] see Figure 1-3 As shown, a double-station pneumatic punching machine includes a double-acting cylinder 1, and the double-acting cylinder 1 includes a cylinder 11 and a piston 12 arranged in the cylinder 11 and capable of moving along its axial direction, wherein the piston 12 is sealed with the cavity wall of the cylinder 11 and divides the inner cavity of the cylinder 11 into two parts, the cylinder 11 is fixedly connected and arranged on the frame, and the axis of the cylinder 11 extends along the horizontal left and right directions. The pneumatic stamping machine also includes a lever 2, the lower end of the lever 2 is rotatably connected to the frame, the upper end of the lever 2 is rotatably connected to a slider 3, and the piston 12 is provided with a slider 3 that can be used for the slider 3 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com