Automatic finger-jointed lumber production line controlled by network system

An automatic production line and network control technology, which is applied to the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve the problems of high after-sales service costs, insufficient reliability of production line operation, and unstable quality, so as to reduce after-sales service costs. Effects of service cost, improvement of processing operation efficiency, improvement of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

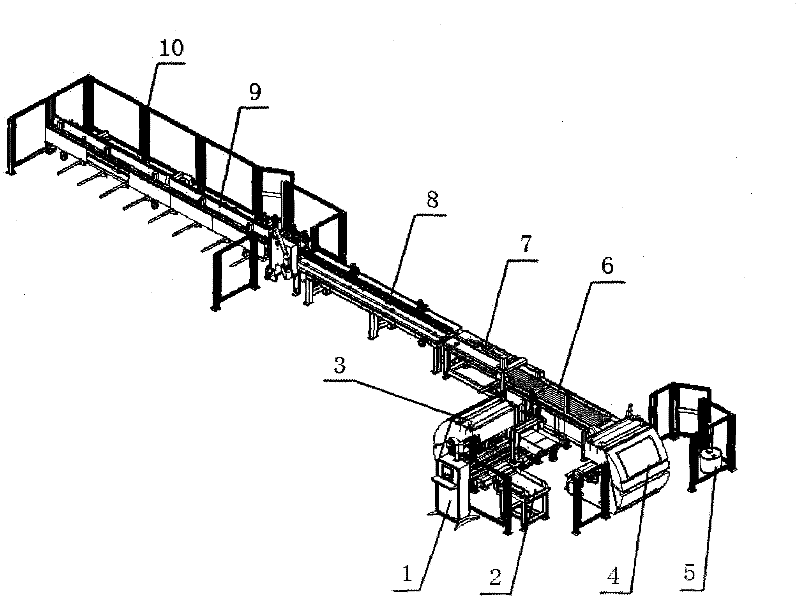

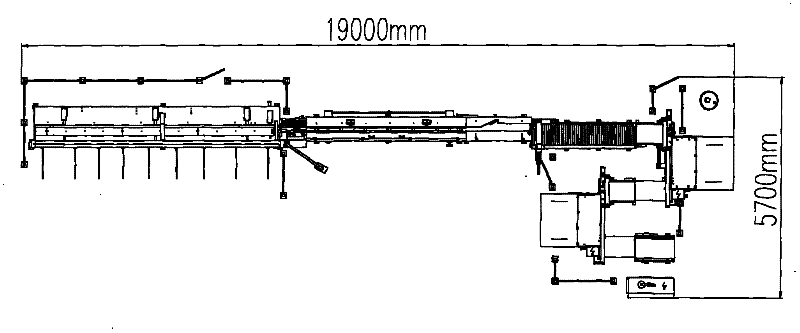

[0011] see figure 1 with figure 2 , the embodiment of the present invention comprises main electric control box 1, feeding conveying table 2, comb tenon tenoning machine (left) 3, comb tenon tenoning machine (right) 4, glue spraying system 5, material distribution conveyor 6 , material turning conveyor 7, preloading conveyor 8, comb tenon butt joint machine 9, safety guardrail 10, and the mechanism units mentioned above are all fixedly placed according to the reference position.

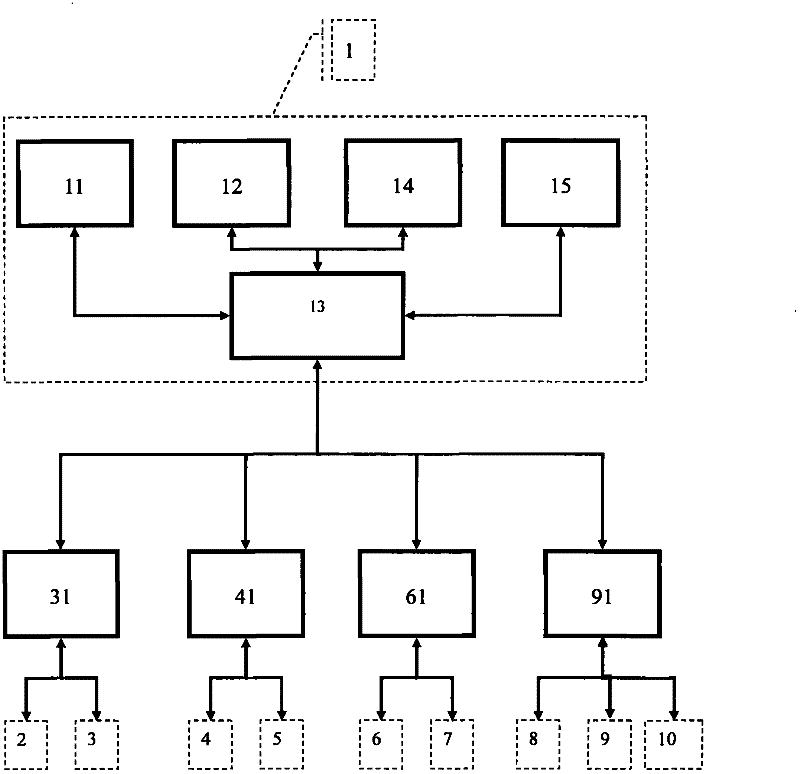

[0012] see figure 1 with image 3 , when the automatic production line is operated and started, first input the required processing operation parameters on the touch screen operation unit 15, and then arrange the wood to be processed vertically on the feeding conveyor table 2 and transmit it to the comb tooth tenoning machine (left) 3 The movable workbench performs positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com