Selective non-catalytic reduction denitration system of circulating fluidized bed boiler

A circulating fluidized bed, selective technology, applied in the field of flue gas denitrification, can solve the problems of affecting the injection effect of reducing agent, the effect of denitrification is not obvious, and the wear of reducing agent nozzle, so as to be suitable for large-scale promotion, beneficial to industrial application, Facilitates a fully proceeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principle, structure and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

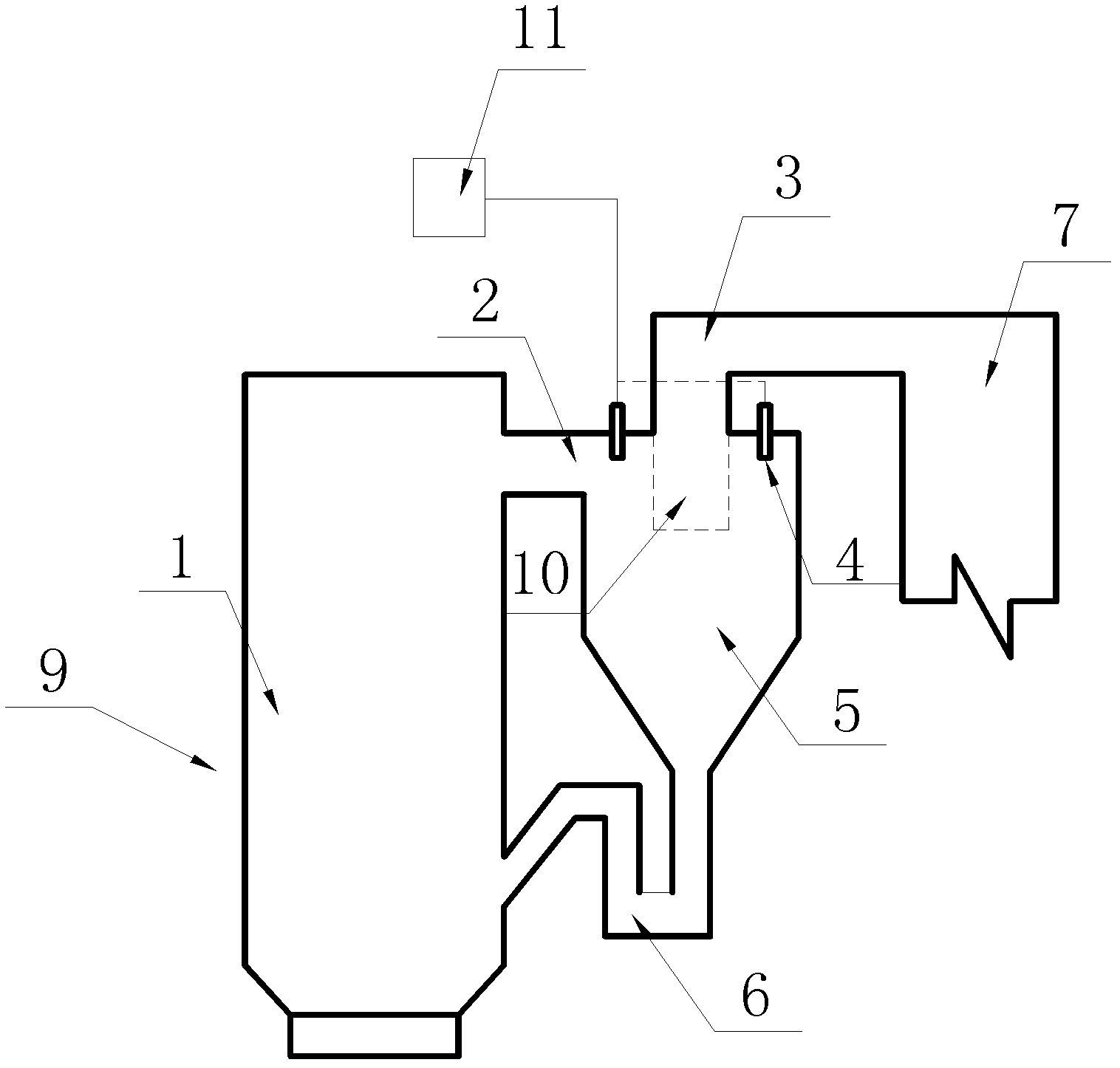

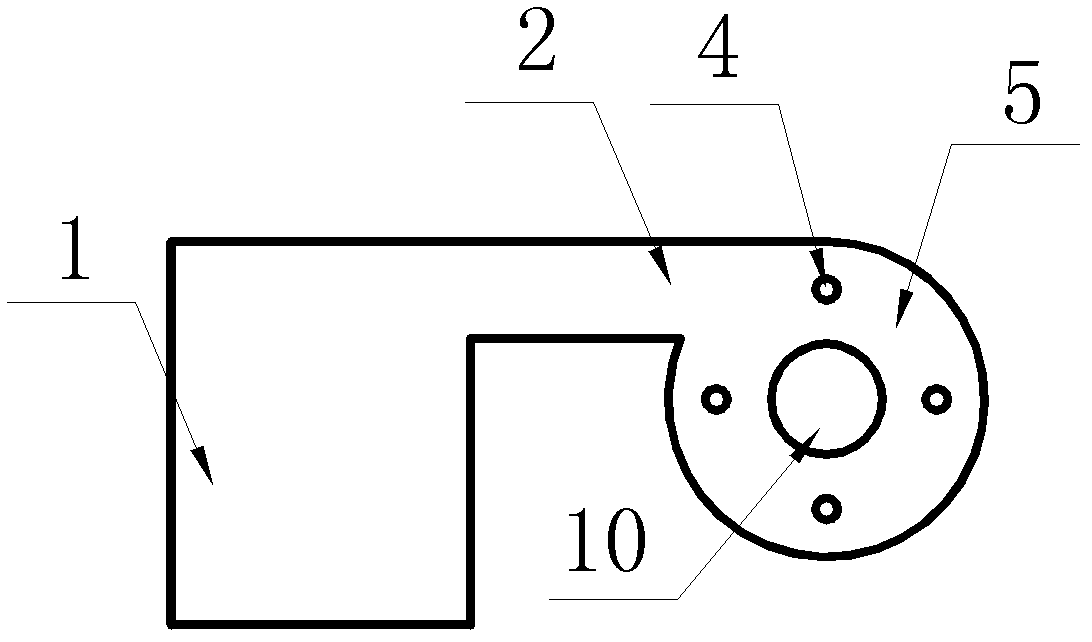

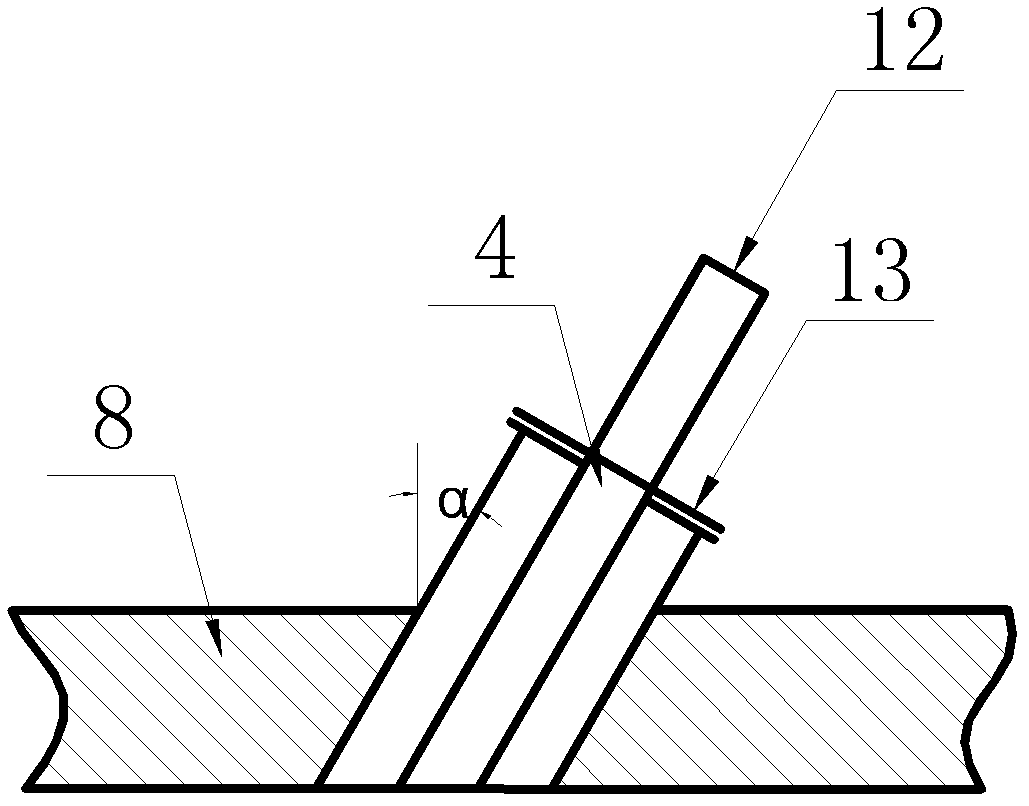

[0016] figure 1 It is a schematic diagram of the overall structure of a selective non-catalytic reduction denitrification system for a circulating fluidized bed boiler. Including furnace 1, reducing agent and atomizing air proportioning conveying system 11, cyclone separator 5, return system 6 and tail flue 7, in order to achieve sufficient mixing of reducing agent and flue gas and improve the degree of SNCR reaction, in the A plurality of atomizing nozzles 4 are evenly arranged on the top plate 8 of the separator on the outer periphery of the cyclone separator core cylinder 10, and the atomizing nozzles 4 are connected to the reducing agent proportioning delivery system 11 through pipelines. figure 2 and image 3 They are respectively the arrangement form of the atomizing nozzle 4 and the specific structure of the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com