Vacuum quantitative filling machine

A filling machine and vacuum technology, applied in the field of food production equipment, can solve the problems of inaccurate ration, affecting food quality, workers and surrounding residents, etc., to reduce noise and prevent fat oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

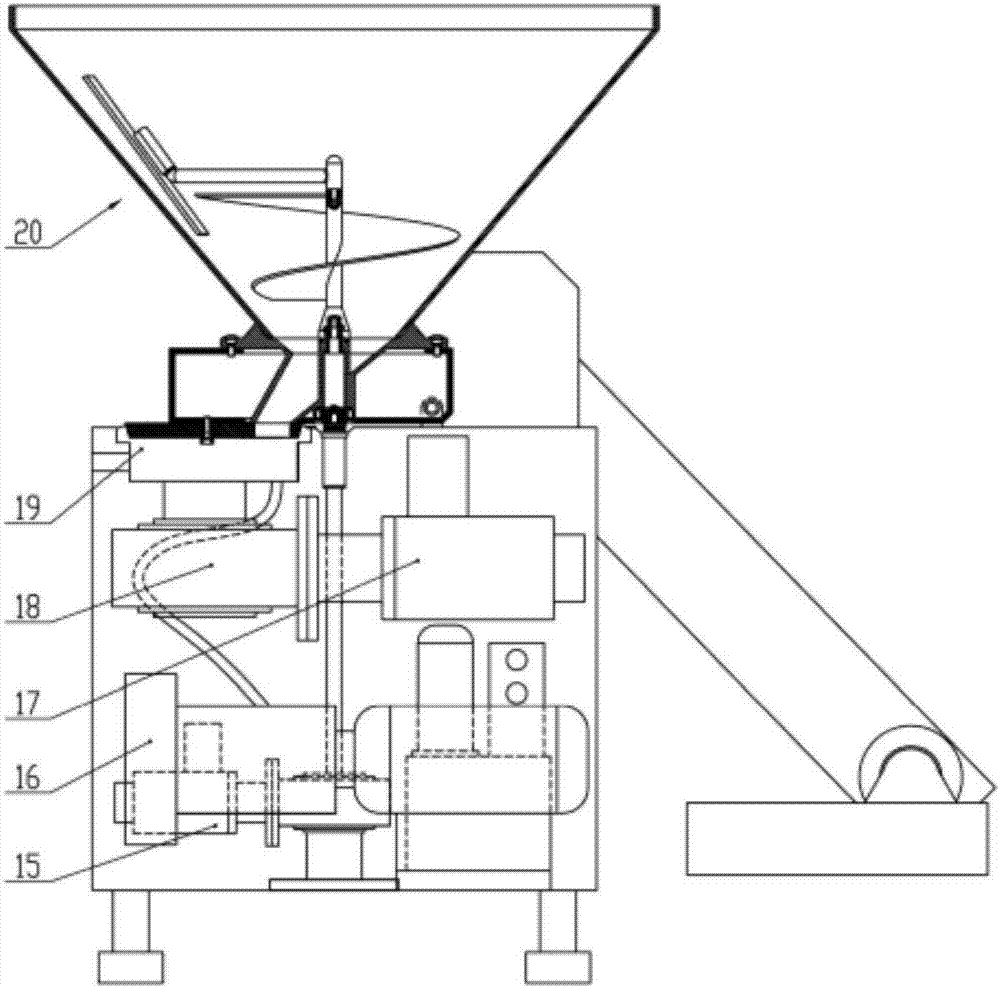

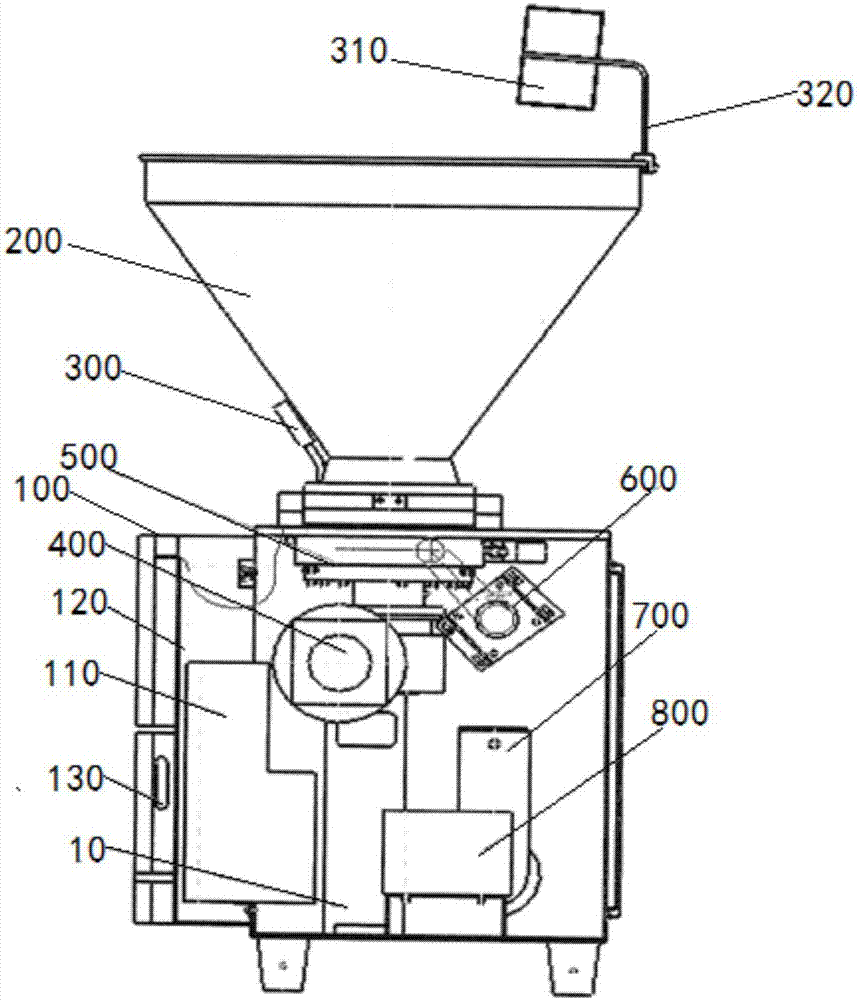

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] see figure 1 The vacuum quantitative filling machine shown includes a main box 100 on which a hopper 200 for feeding materials is arranged, and a locking handle 300 is also arranged between the main box 100 and the hopper 200 .

[0018] There is a main motor 400 connected to the pump body 500 on the main box 100, and a torsion motor 600 connected to the pump body 500, equipped with a convenient and fast automatic twisting device, which can automatically twist natural knot casings, protein casings and collagen casings, etc. .

[0019] On the main machine box 100 and below the twisting motor 600, a material storage box 700 is arranged, and a vacuum pump 800 is arranged on one side of the material storage box 700. The filling process of the whole machine in a vacuum state can effectively prevent and control fat oxidation. Avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com