Dust remover

A dust collector, dust and gas separation technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of increasing energy consumption and operating costs, increasing equipment investment and floor space, etc., to achieve a combined structure Simple and easy, manufacturing and installation costs and low footprint, consumable savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

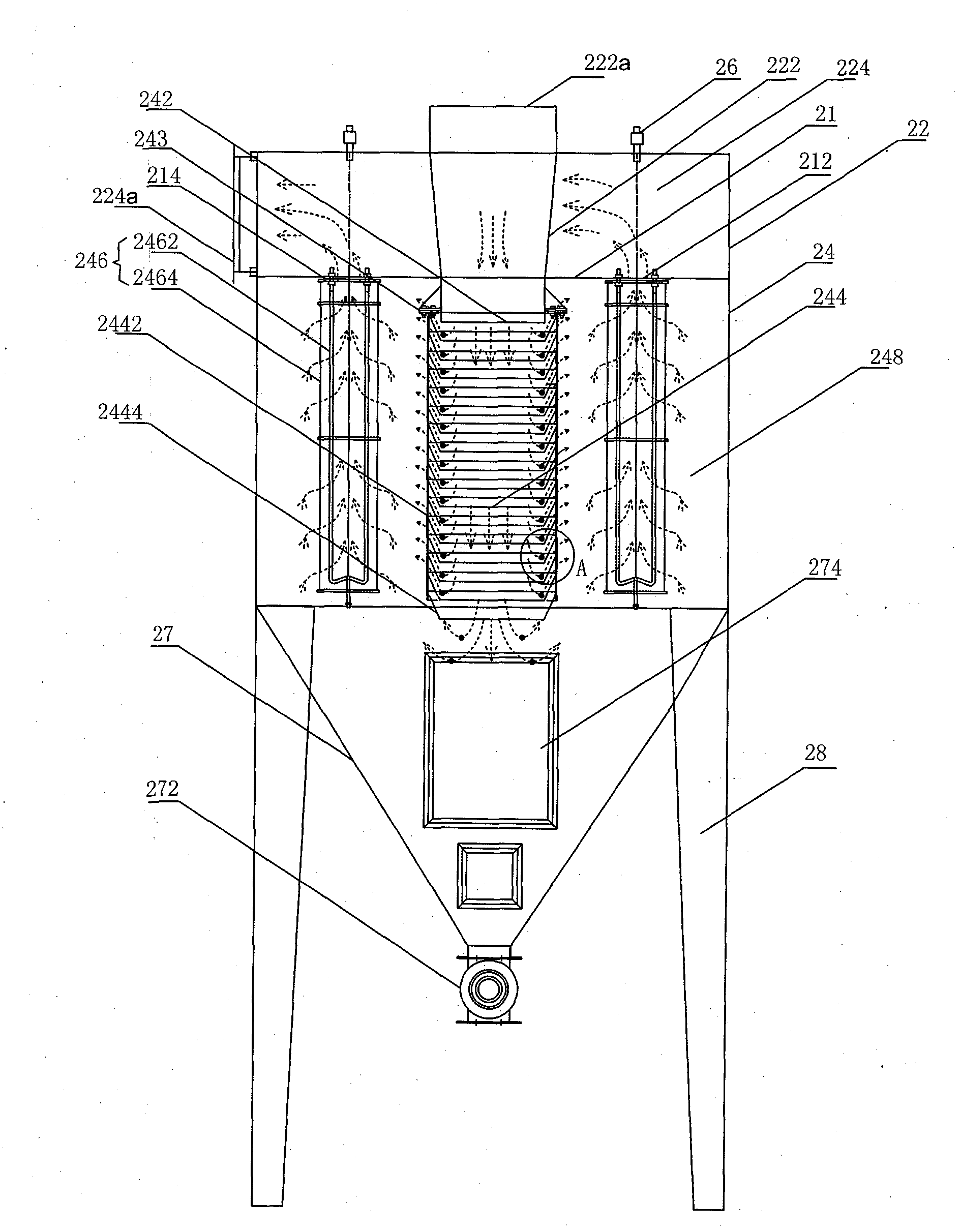

[0024] see figure 2 , which is a structural schematic diagram of the bag filter of the present invention. The bag filter 20 includes a dust removal device 26 , an upper box 22 , a middle box 24 , an ash hopper 27 and supporting feet 28 from top to bottom.

[0025] The upper box body 22 is a closed space, including an exhaust gas intake passage 222 and a clean air chamber 224 . The exhaust gas inlet channel 222 is a closed channel arranged in the middle of the upper box body 22 and runs through its upper and lower ends, and the upper part of the exhaust gas inlet channel 222 is an exhaust gas inlet 222a. The space in the upper case 22 except for the exhaust gas intake passage 222 is a clean air chamber 224 . A side wall of the clean air chamber 224 of the upper case 22 has a clean air outlet 224a.

[0026] The middle box 24 is arranged below the upper box 22, and forms a closed space with the ash hopper 27 below it. The middle box 24 includes an exhaust gas inlet 242 , a d...

Embodiment 2

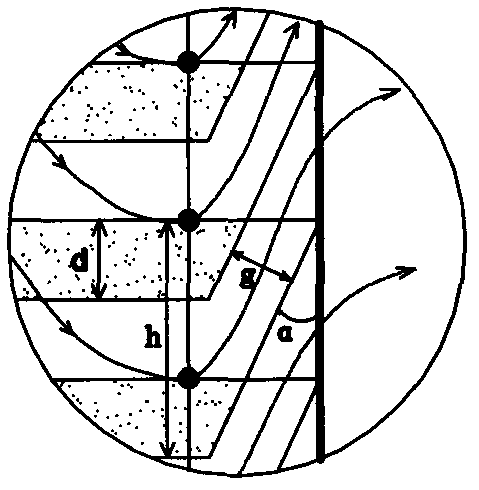

[0040] This embodiment is substantially the same as Embodiment 1, and the only difference is that the vertical height h between the upper and lower end openings of the platform formed by the blades is 120 mm, and the angle α between the blades 2444 and the bracket 2442 is 25°, correspondingly The vertical height d of the overlapping portion between two adjacent blades is 40mm, and the gap g between the overlapping portions of two adjacent blades is 33.8mm. The number of leaves is 16. The number of fixed brackets is 3. The waste gas inlet 242 is directly inserted into the dust and gas separation device 244, and the vertical height of the overlapping part of the blade of the dust and gas separation device is 40mm.

Embodiment 3

[0042] This embodiment is substantially the same as Embodiment 1, the only difference being that the height h between the upper and lower end openings of the platform formed by the blades is 180 mm, the angle α between the blades 2444 and the bracket 2442 is 45°, adjacent The vertical height d of the overlapping portion between the two blades is 60 mm, and the gap g between the overlapping portions of two adjacent blades is 85 mm. The number of leaves is 11. The number of brackets is 4. The exhaust gas inlet 242 is directly inserted into the dust and gas separation device 244, and the vertical height of the overlapping part of the blade of the dust and gas separation device is 60 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com