Seasoning as well as preparation method and use method thereof

A condiment and process technology, applied in food preparation, application, food science and other directions, can solve problems such as nitrite poisoning, and achieve the effects of delicious taste, simple process, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of condiment of the present invention comprises following steps:

[0028] (1) The process of adding koji bacteria to the cooked grains for fermentation to prepare koji seeds;

[0029] (2) After uniformly mixing the koji and salt obtained in step (1), adding water and mixing;

[0030] (3) A step of fermenting and aging the mixture obtained in step (2).

[0031] Process (1) is a traditional method for preparing koji. Specifically, koji bacteria are added to the cooked grains and fermented to prepare koji.

[0032] There are no special restrictions on the grains used to prepare distiller's yeast, rice (rice, etc.), wheat (wheat, barley, oats, etc.), cereals (millet, millet, etc.), beans (soybeans, broad beans, peas, mung beans, etc.) etc.), potatoes (sweet potatoes, potatoes, yams, etc.), corn, sorghum, etc. Among them, grains with shells such as rice and wheat need to be dehulled before cooking.

[0033] There is no particular limitation on the ...

Embodiment 1

[0053] Add self-made koji (2g koji / kg rice) to the cooked rice, ferment at 35°C for 48 hours, and turn the fermented product every day during the fermentation process to get koji (process (1)). Take a plastic box, add 300g of the prepared koji into it, stir the koji, add 60g of salt to it and mix evenly, then add 300g of warm water (30°C) and mix well (step (2)). Ferment the obtained mixture for 1 week under the condition of 25° C., stir 1-2 times a day, and add water appropriately in the initial stage, so that the water is always kept to the degree of just submerging the fermented product, and seasoning 1 (process (3 )). The salinity of seasoning 1 was 9% by mass, the solid content was 40% by mass, and the pH was 4.5.

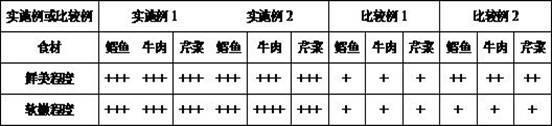

[0054] Cut cod and beef into small pieces, and celery into small pieces. Add condiment 1 to each ingredient at a ratio of 10% of the weight of the ingredients and stir evenly. After standing for 2 hours, cook the cooked dishes. 10 volunteers conducted the t...

Embodiment 2

[0056] Wash 100g of fresh hawthorn and remove the core, add 100g of water, boil it until the hawthorn is thoroughly cooked, and then use a diatomaceous earth filter (manufactured by Qingdao Guangda Equipment Technology Co., Ltd.) to filter out the hawthorn meat and skin, and the juice obtained is A water extract of Hawthorn. Except that the water used in the step (2) of preparing the seasoning 1 was replaced with the water extract of the hawthorn, the rest of the preparation process was the same as that of Example 1, and the seasoning 2 was obtained. The salinity of seasoning 2 was 9% by mass, the solid content was 39% by mass, and the pH was 4.3.

[0057] Except changing condiment 1 into condiment 2, other is the same as embodiment 1, other auxiliary materials of dishes are the same, and each food material is cooked by the same chef, and the same volunteers are asked to taste, and the evaluation results are shown in Table 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com