Liquid detergent composition

A cleaning agent and composition technology, which is applied in the field of liquid cleaning agent compositions, can solve the problem that functional components such as enzymes and chelating agents cannot be fully mixed, and achieve excellent low-temperature solubility and sebum cleaning ability, and good low-temperature storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~48

[0284] >

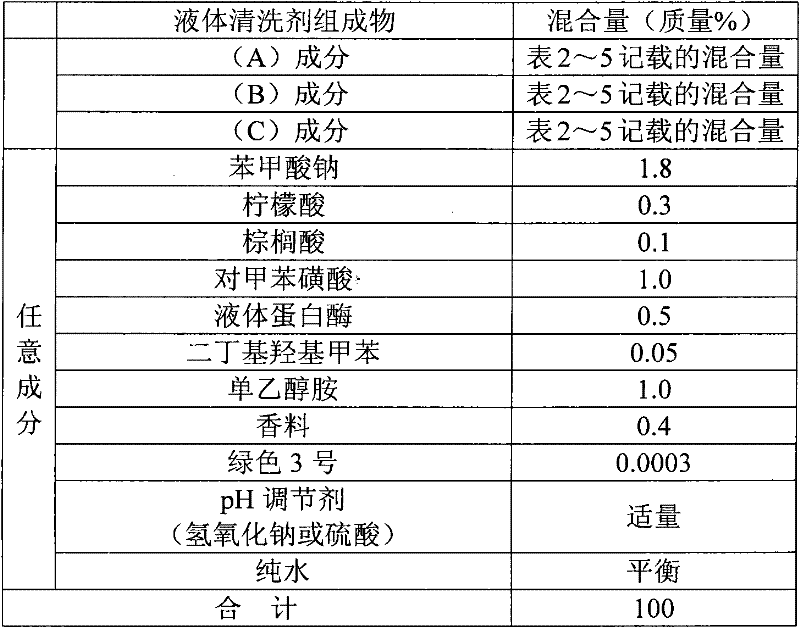

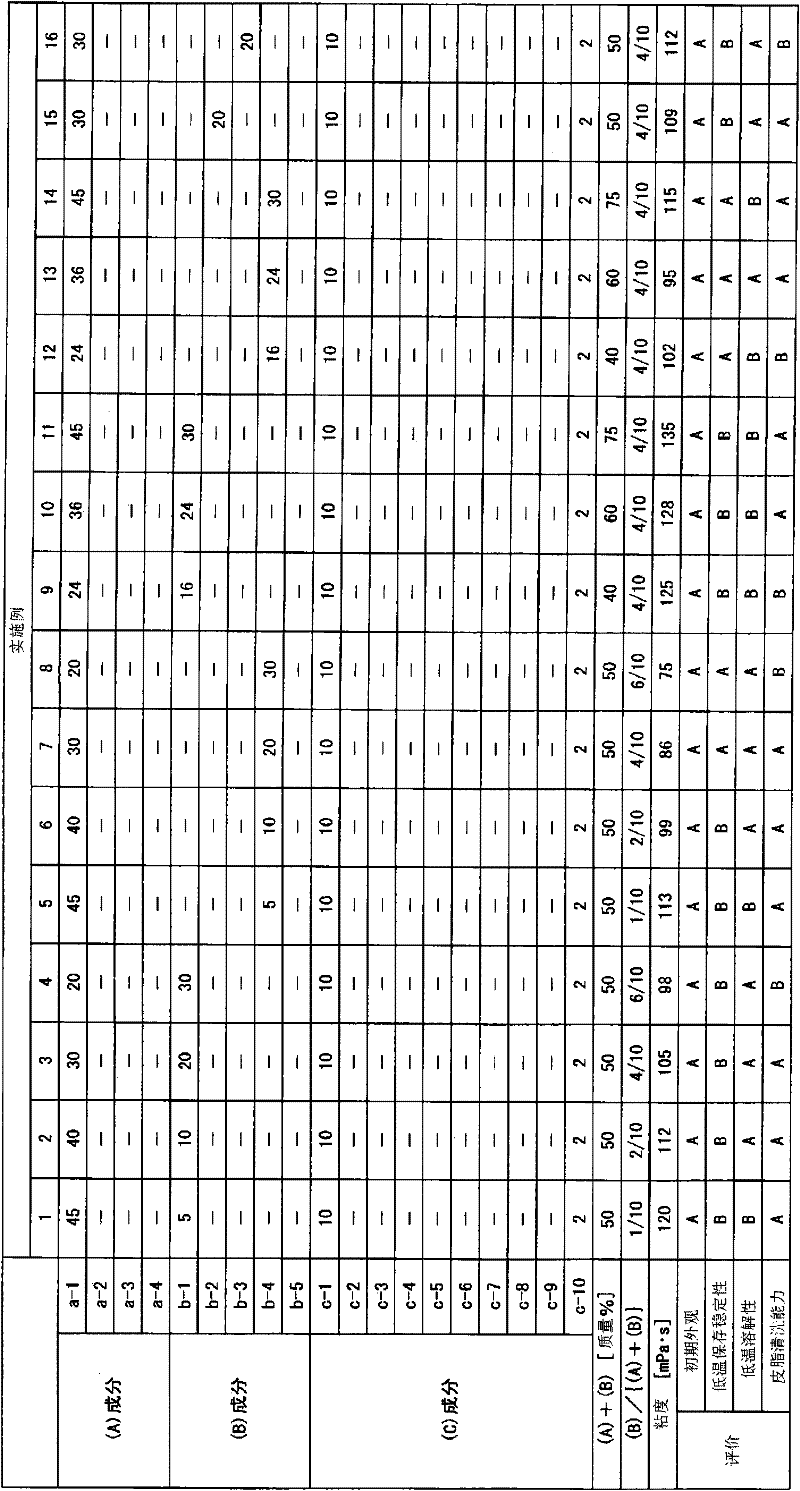

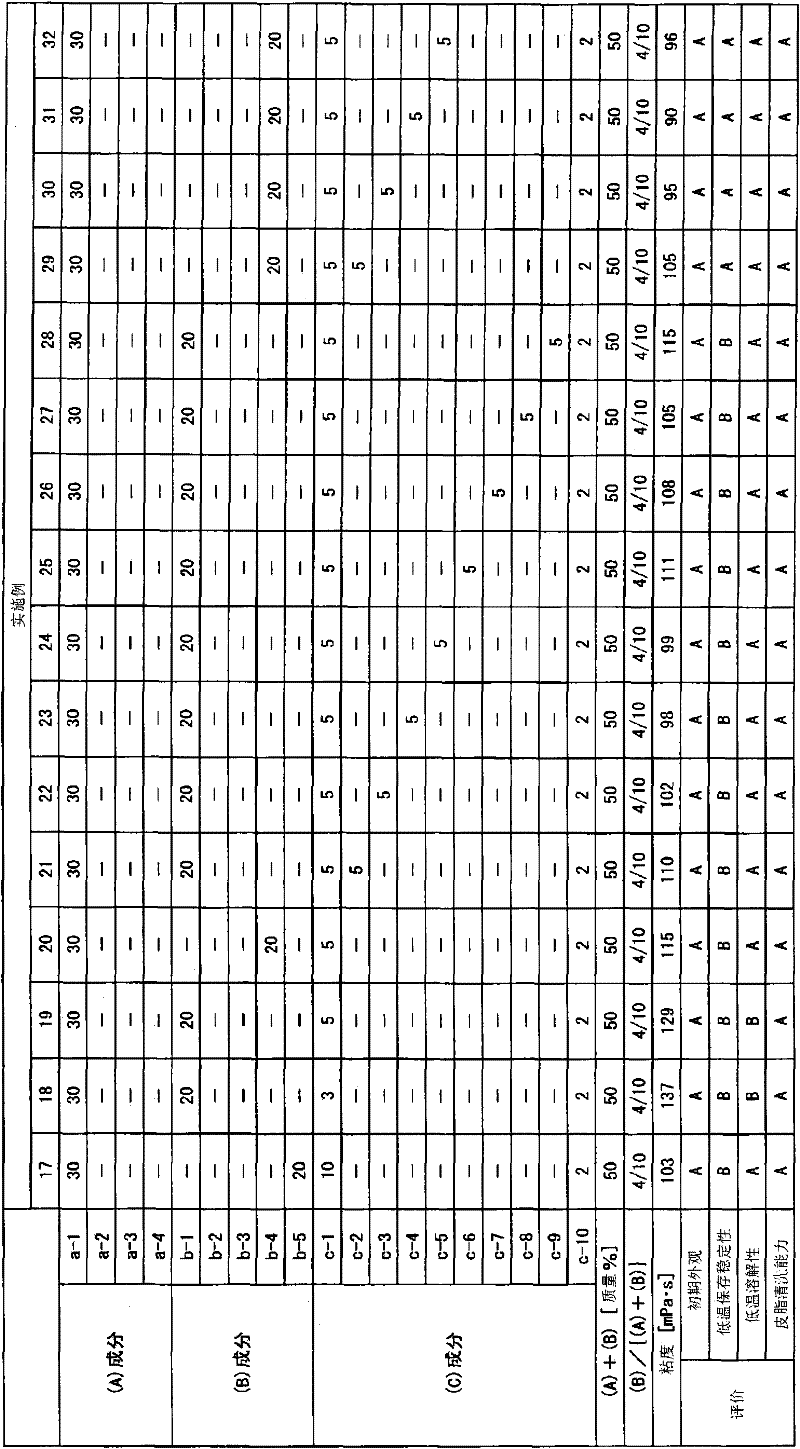

[0285] Into a 500 mL beaker, each component was put into a 500-mL beaker according to the composition shown in Tables 2 to 5, and the mixture was fully stirred with a magnetic stirrer (MITAMURAKOGYO INC.). Next, arbitrary components (except pure water) were added in the mixing amounts shown in Table 1, and pure water was added while stirring so that the total amount became 98% by mass, and further stirred. After adding an appropriate amount of pH adjuster (sodium hydroxide or sulfuric acid) so that the pH at 25°C would be 7.0, pure water was added so that the total amount would be 100% by mass to obtain a liquid cleaning composition.

[0286] Various measurements and evaluations were performed on the obtained liquid cleaning composition. The results are shown in Tables 2-5.

[0287] In addition, the unit of the compounding quantity in Tables 2-5 is mass %, and the arbitrary component shows the purity conversion quantity.

[0288] [Table 2]

[0289]

[0290] [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com