Protective bag

A protective bag, air permeability technology, applied in the direction of plant protection, plant protection cover, separation method, etc., can solve the problem of unable to prevent agricultural products from falling fruit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

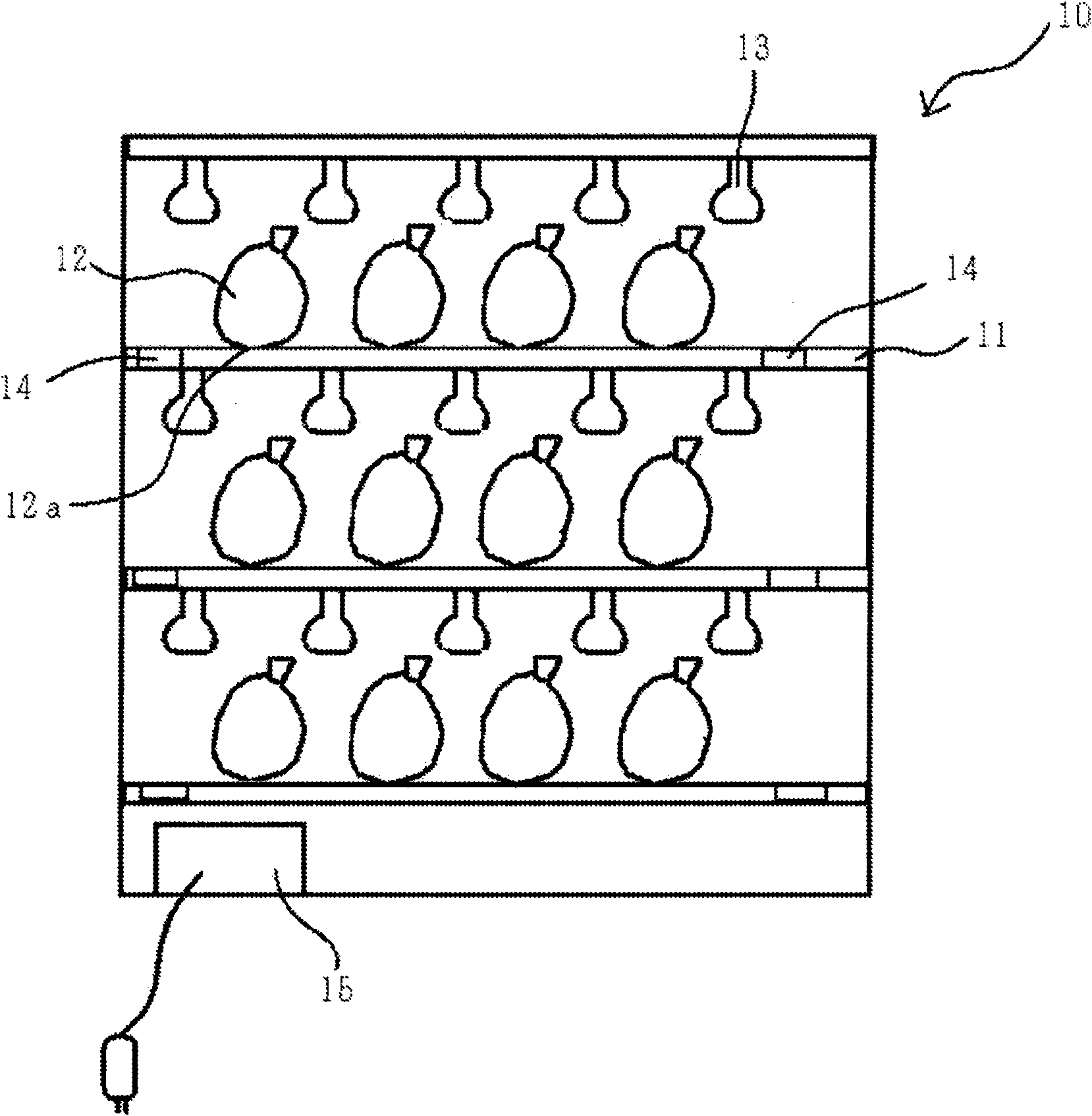

[0221] (Example 1: Carrying photocatalyst titanium apatite, coated with light reflective material, the shape of the protective bag is spherical, the structure of the protective bag is formed without recesses on the surface, and the material of the protective bag is non-woven fabric)

[0222]

[0223] A spherical air-permeable bag with a diameter of 300 mm (trade name "fruit bag", manufactured by Sato Sesaku) made of nonwoven fabric (material: pulp, PE, etc.) was prepared. The air-permeable bag was immersed in the aqueous dispersion of photocatalyst titanium apatite prepared as follows for 10 seconds, and dried at 120° C. for 3 hours to make it support the photocatalyst titanium apatite. The prepared aqueous dispersion of the light reflective material was sprayed and dried at 120° C. for 3 hours, and then coated with the light reflective material on the outer surface.

[0224] — Preparation of Photocatalyst Titanium Apatite Aqueous Dispersion —

[0225] As the photocatalyst ...

Embodiment 2

[0274] (Example 2: the shape of the protective bag is cube-shaped)

[0275] Except that by using the spherical gas permeable bag of Example 1 and the same surface area as a cube-shaped gas permeable bag with a length of 100 mm to make a protective bag, the same operation was carried out as in Example 1, and the production and evaluation of the protective bag were carried out ( Measurement of photocatalyst titanium apatite loading capacity of protective bag, measurement of coating amount of light reflective material of protective bag, measurement of light reflectance of protective bag, measurement of ethylene gas permeability of protective bag, ethylene gas adsorption of protective bag or degradation performance), cultivation experiments (measurement of ethylene gas concentration, fruit drop rate, bird damage rate, mold rate), storage experiments (ethylene gas concentration, spoilage rate) , Determination of decay rate on the bottom side, measurement of heat retention effect). ...

Embodiment 3

[0276] (Example 3: The shape of the protective bag is a bellows (level difference) type shape)

[0277] Except that by using 100 parallel gas-permeable spherical bags with a width of 10 mm and a height of 0.5 mm to make a protective bag, the protective bag was prepared in the same manner as in Example 1. and evaluation (measurement of the photocatalyst titanium apatite loading capacity of the protective bag, measurement of the coating amount of the light reflective material of the protective bag, measurement of the light reflectance of the protective bag, measurement of the ethylene gas permeability of the protective bag, the measurement of the protective bag Measurement of ethylene gas adsorption or degradation performance), cultivation experiments (measurement of ethylene gas concentration, measurement of fruit drop rate, measurement of damage rate caused by birds, measurement of moldy rate), storage experiments (measurement of ethylene gas concentration, decay Determination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com