Graphene radiation material, and preparation method and application thereof

A heat dissipation material, graphene technology, applied in the direction of cooling/ventilation/heating transformation, layered products, etc., can solve problems such as difficult application of electronic equipment, size limitation of artificial synthetic graphite, difficult electronic equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

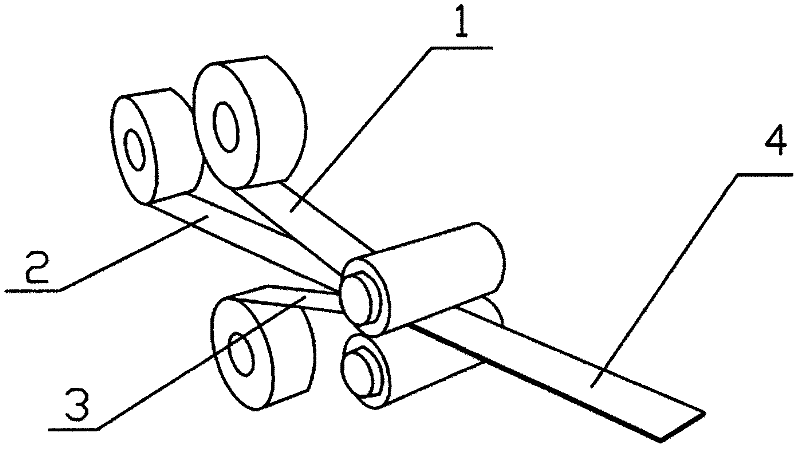

[0043] Such as Figure 1-2 As shown, it is a single-layer graphene heat dissipation film 4, including a supporting layer 1, a graphene layer 2 and an adhesive layer 3 combined with each other, and the graphene layer is located between the supporting layer and the adhesive layer, and is a monomolecular thickness Graphene or graphene composite material, graphene layer 2 is a graphene film with a plane thermal conductivity between 400W / mk-3000W / mk, preferably a graphene film with a thermal conductivity between 600W / mk-1500W / mk, and the thickness 5um, the support layer 1 is insulating resin with a thickness of 0.01mm, and the adhesive layer 3 is hot melt with a thickness of 0.005mm.

Embodiment 2

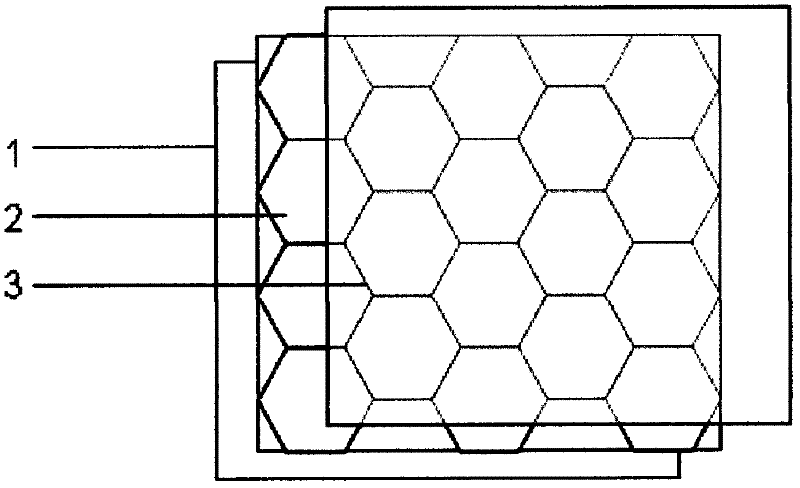

[0045] Such as image 3 , is a composite graphene heat dissipation film, wherein, the graphene layer 2 is a multilayer, the graphene layer 2 is a graphene film with a thermal conductivity between 600W / mk-1500W / mk, and the thickness is 50um, and the supporting layer 1 is a metal sheet The surface tape has a thickness of 0.05 mm, and the adhesive layer 3 is a pressure-sensitive adhesive with a thickness of 0.05 mm.

Embodiment 3

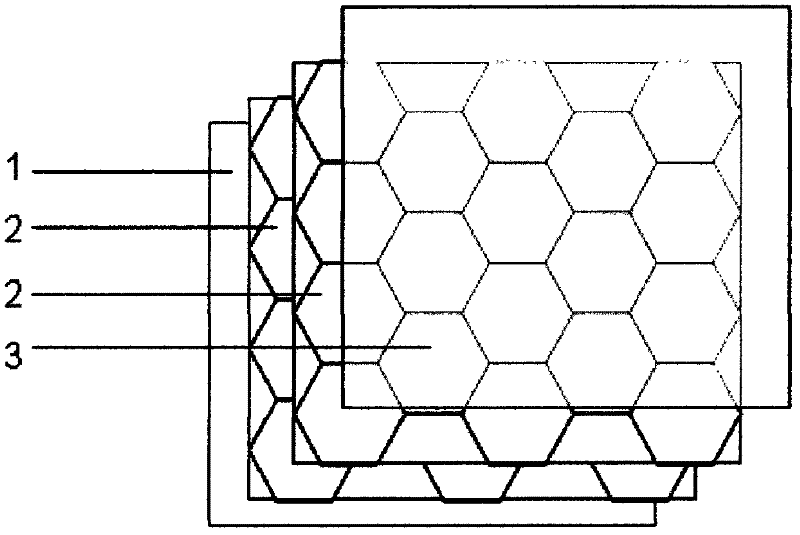

[0047] Such as Figure 4 , is a multilayer graphene heat dissipation film, including a multilayer graphene heat dissipation film 4, graphene layer 2 is a multilayer, graphene layer 2 is a graphene film with a thermal conductivity between 600W / mk-1500W / mk, and the thickness is 50um, the support layer 1 is a metal single-sided adhesive tape with a thickness of 0.03mm, and the adhesive layer 3 is a pressure-sensitive adhesive with a thickness of 0.01mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com