Foot-warming heating sheet with nano carbon electric heating films

A nano-carbon and electric heating film technology, applied in ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of not being able to bring economic benefits to enterprises, low electric heating soft exchange rate, etc., to achieve faster heating speed, better Economic and social benefits, far-infrared effects are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

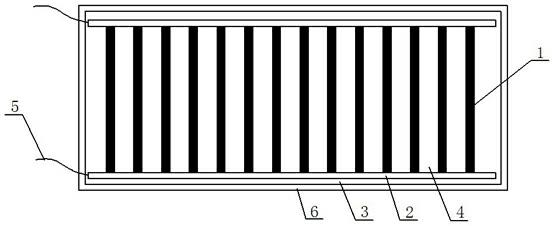

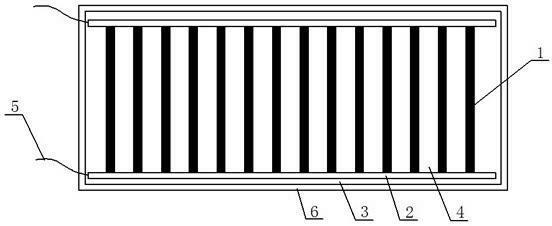

[0008] A kind of nanometer carbon electric heating film foot warmer heating sheet described in the present invention, its structural composition is described again with reference to accompanying drawing: use mica sheet as the insulating material layer of electric heating sheet, is made of nanometer carbon electric heating elongated film Sheets 1 are arranged at equal intervals of 4 to sandwich a heating block made of insulating material layer and sealing film material layer 3. The electrodes at both ends of each nano-carbon strip-shaped diaphragm 1 are respectively connected by copper foil 2, and the electrodes of the two poles of copper foil 2 One end is respectively connected to the lead wire 5, and the upper and lower layers of the sealing film material layer 3 are used to flatly seal a plurality of nano-carbon strip-shaped diaphragms 1 and the connected copper foil 2 in the heating film block, and place them in There are ample insulating material layer and margin 6 on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com