High voltage insulation current lead for superconductive electric device

A technology for power devices and insulation currents, applied in the field of current leads, can solve problems such as unstable insulation capacity and complex structure, and achieve the effect of solving high-voltage insulation technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

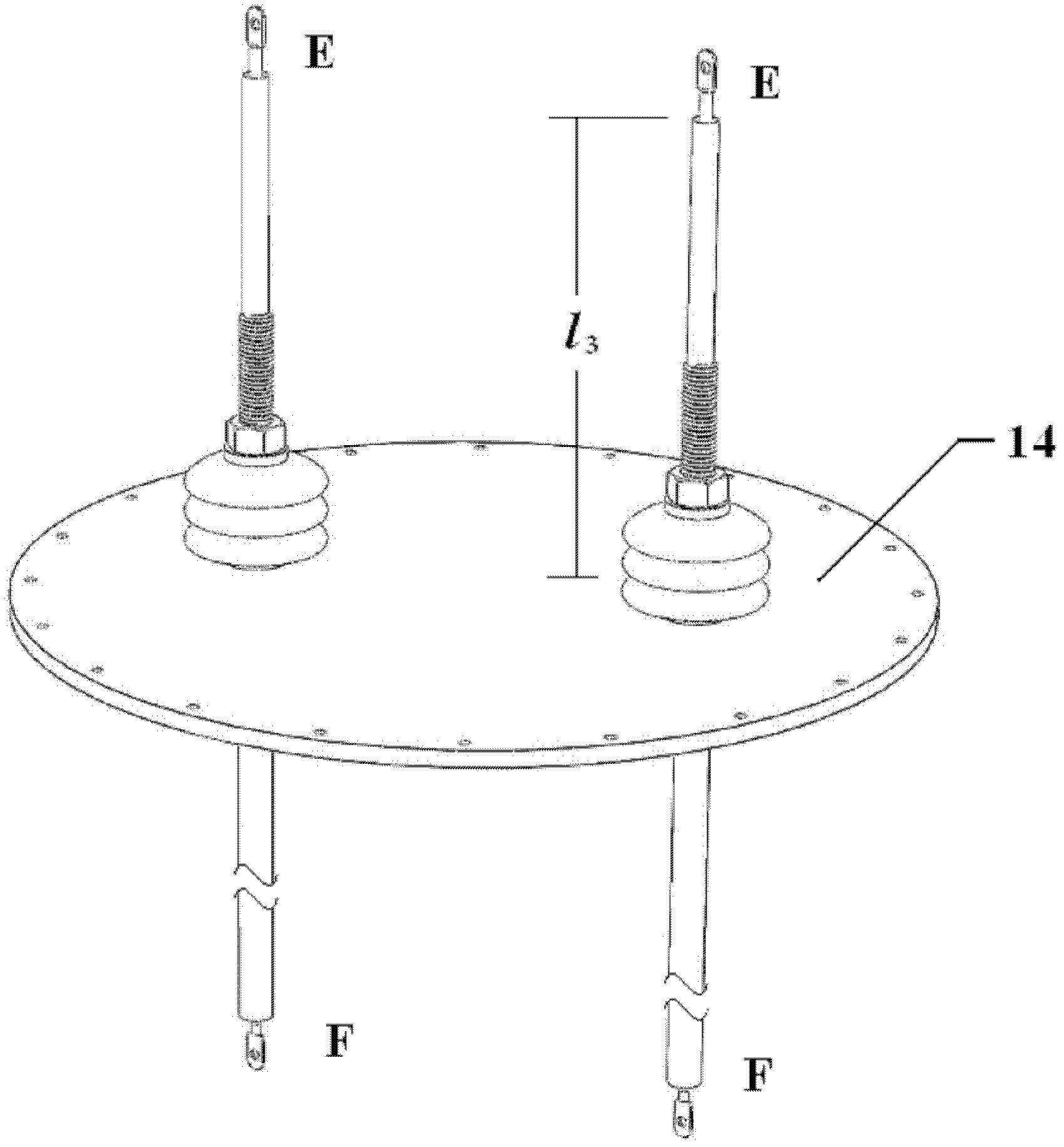

[0020] The low-temperature and high-voltage insulated lead wire of the present invention is mainly composed of: copper conductor 1, insulating sleeve 3, wiring lug 6, insulator 11, lower sealing O-ring 9, middle sealing O-ring 10, upper sealing O-ring 12 and low-temperature container flange 14, etc. components.

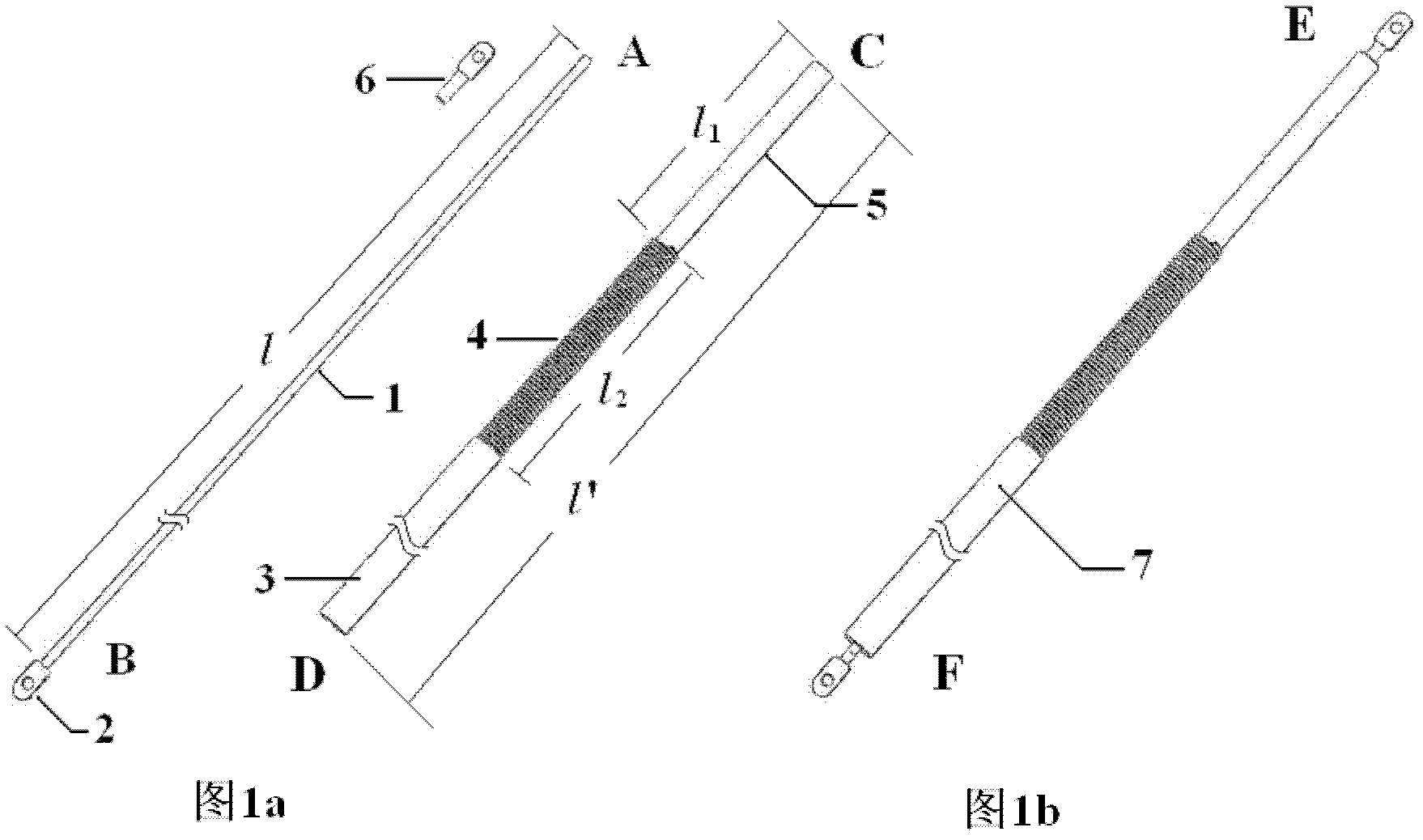

[0021] Such as figure 1 As shown in a, the copper conductor 1 is a copper rod with uniform thickness. The low-temperature end B of the copper conductor 1 is inserted into the low-temperature container. There is a prefabricated terminal 2 at the end of the low-temperature end B of the copper conductor 1. The length of the copper conductor 1 is l. The insulating sleeve 3 is made of a material with good electrical insulation performance and good mechanical performance at low temperature, usually a glass fiber reinforced plastic pipe. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com