Bistable liquid crystal grating

A bistable liquid crystal and grating technology, applied in optics, nonlinear optics, static indicators, etc., can solve the problem of insufficient energy saving, and achieve the effect of energy saving and adjustable electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

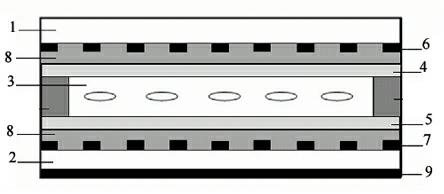

[0020] refer to figure 1 and Figure 5 , the present invention is a bistable liquid crystal grating, comprising an upper glass substrate 1 and a lower glass substrate 2, and a liquid crystal layer 3, the two glass substrates are soda-lime glass, and the upper and lower glass substrates 1 and 2 are provided with combs A transparent electrode layer and an alignment layer. The lower glass substrate 2 is provided with a light absorbing layer 9. The alignment layer is divided into an upper alignment layer 4 and a lower alignment layer 5. The upper alignment layer 4 and the lower alignment layer 5 are rubbed alignment layers. A barrier layer 8 is provided between the upper and lower glass substrates 1, 2 and the upper and lower alignment layers 4, 5 respectively, the barrier layer 8 is silicon dioxide, and the liquid crystal layer 3 is arranged between the two glass substrates 1, 2, The liquid crystal poured into the liquid crystal layer 3 is cholesteric liquid crystal, the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com