Chromatographic column, preparation method thereof and application thereof to analysis of mixture comprising 1,2-dichloroethane, ethyl chloride, methyl chloride and/or vinyl chloride

A technique for analyzing dichloroethane and gas chromatography, which is applied in the field of preparing the chromatographic column, can solve the problems of high requirements for sample gas pretreatment, complicated methods, expensive equipment and the like, and achieves the effects of effective separation and accurate quantification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The feed gas stream with the following composition was fed for 4500 h -1 The space velocity is fed in the ethylene oxide industrial production device, and the bed layer of 26 tons of YS-7 type silver catalysts (Sinopec Catalyst Beijing Yanshan Branch) is housed in the device:

[0055] Ethylene 28.5 mol%;

[0056] Oxygen 7.90 mol%;

[0057] Carbon dioxide 6.50 mol%;

[0058] Ethane 0.35 mol%;

[0059] Methane 46.2 mol%;

[0060] Ethylene oxide 2.50 mol%.

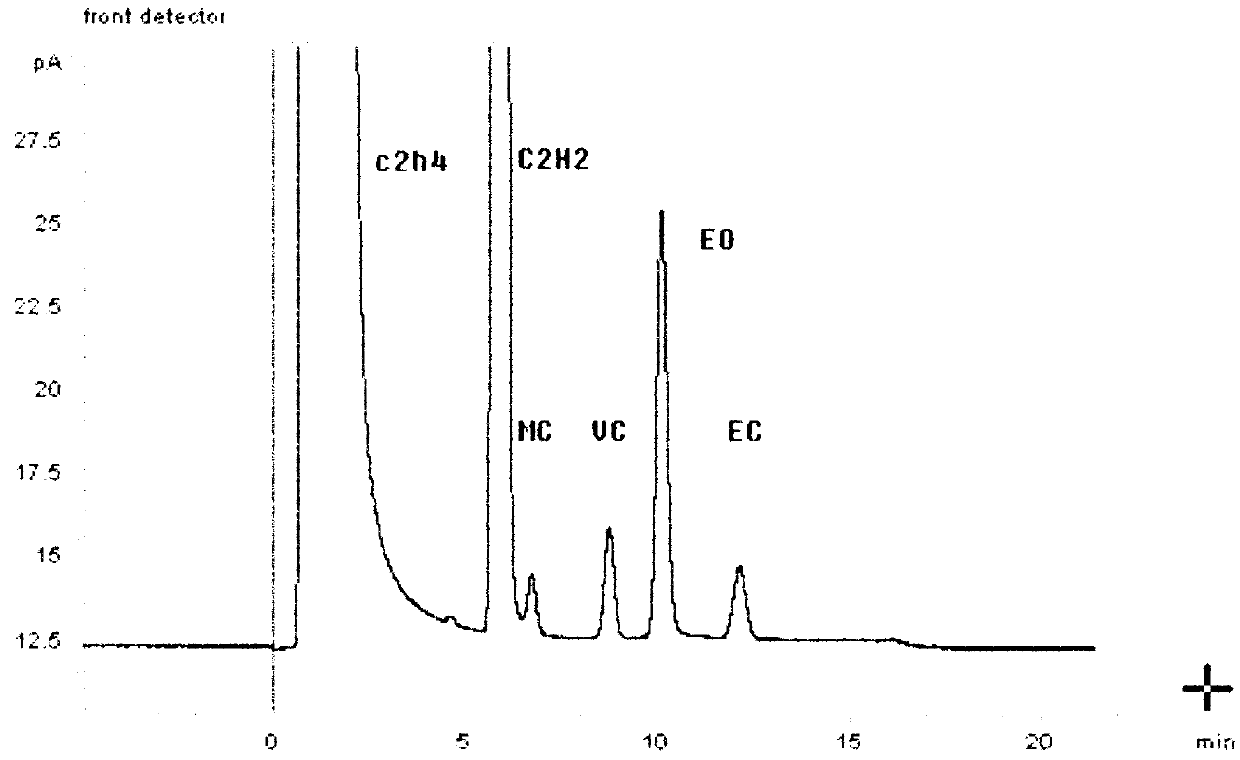

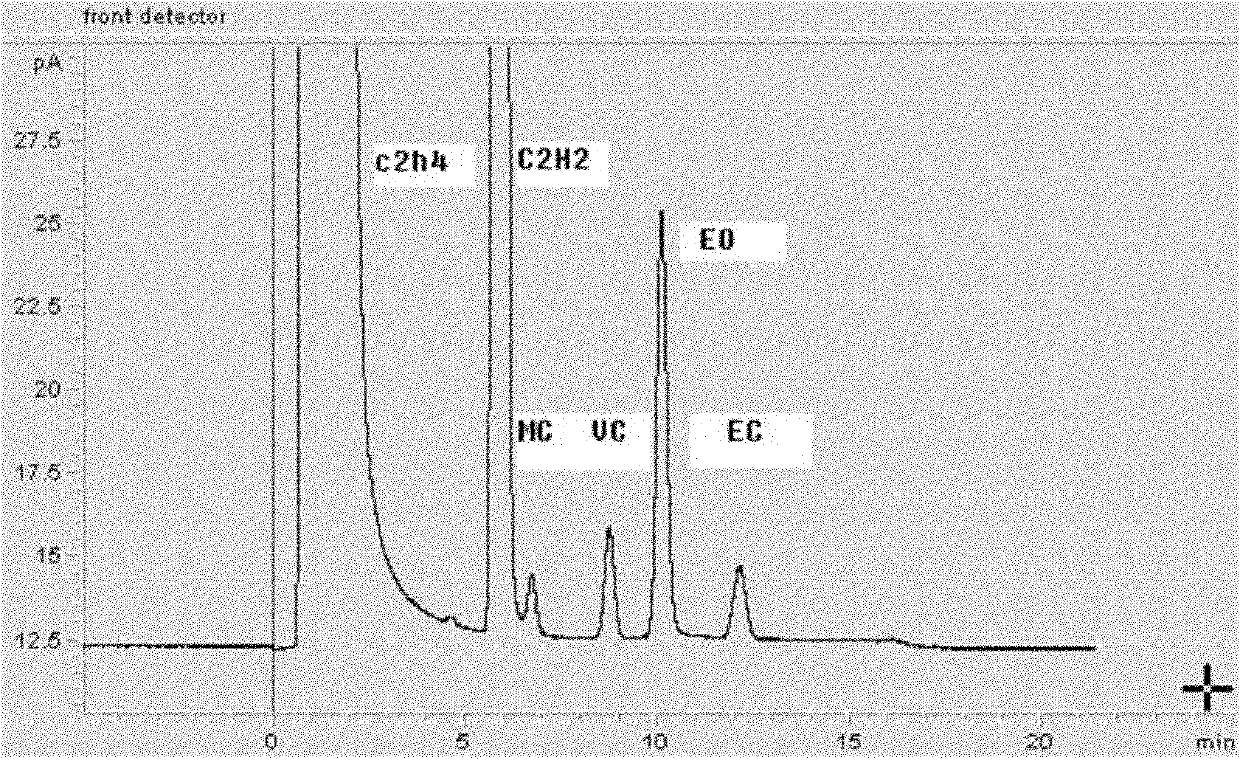

[0061] Simultaneously, ethylene chloride was added as an inhibitor to the feed gas stream at a flow rate of 385 g / h, and ethylene and oxygen were reacted to generate ethylene oxide at a temperature of 225° C. and a pressure of 2.1 MPa. The product gas stream is withdrawn from the unit and the desired product ethylene oxide is separated off. A gas mixture comprising mainly unreacted ethylene and oxygen is recycled to the plant. At this point, the chlorides in the recycle gas stream that need to be analyzed by gas...

Embodiment 2

[0072] The feed gas stream with the following composition was fed for 5000 h -1 The space velocity is fed in the ethylene oxide industrial production unit, and the bed layer of 24 tons of YS-7 type silver catalysts (Sinopec Catalyst Beijing Yanshan Branch) is housed in said unit:

[0073] Ethylene 29.1 mol%;

[0074] Oxygen 8.10 mol%;

[0075] Carbon dioxide 5.50 mol%;

[0076] Ethane 0.25 mol%;

[0077] Methane 48.8 mol%;

[0078] Ethylene oxide 2.35 mol%.

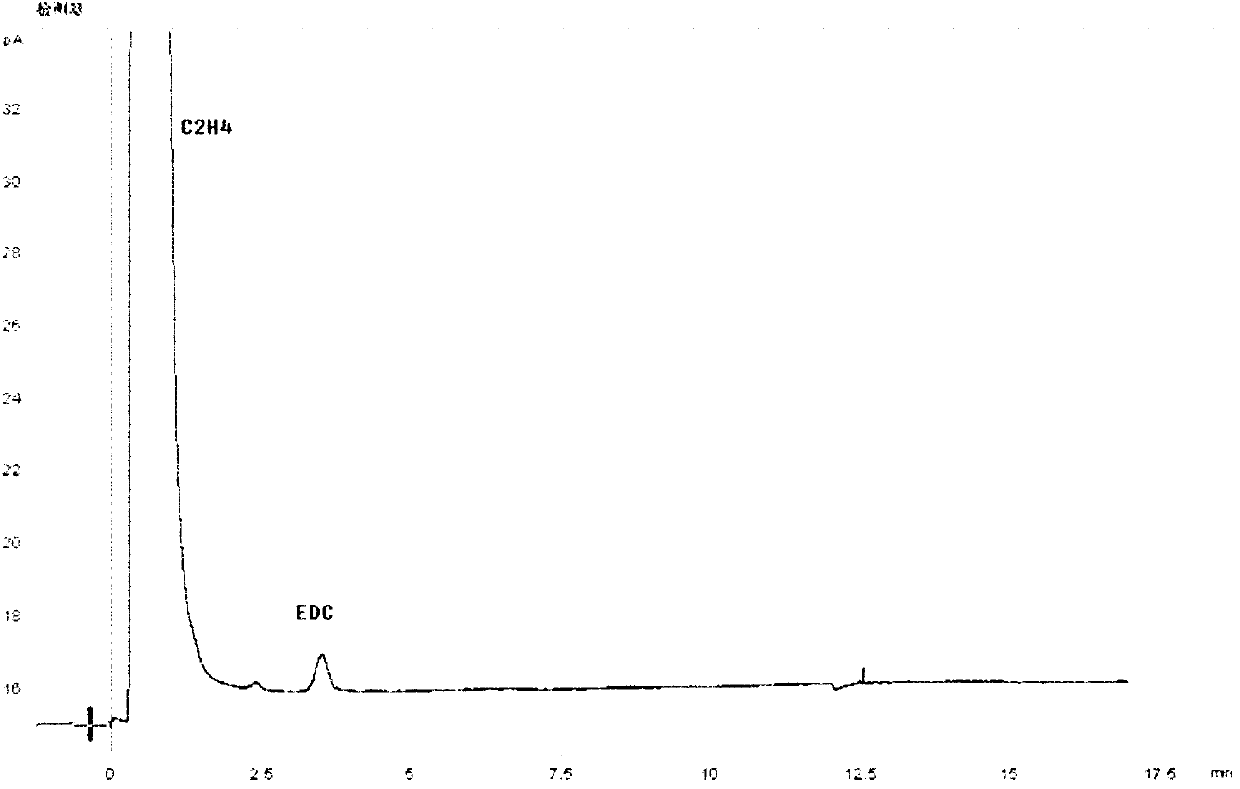

[0079] At the same time, 1,2-dichloroethane was added to the feed gas stream at a flow rate of 150 g / h as an inhibitor, and ethylene and oxygen were reacted to generate ethylene oxide at a temperature of 238° C. and a pressure of 2.1 MPa. The product gas stream is withdrawn from the unit and the desired product ethylene oxide is separated off. A gas mixture comprising mainly unreacted ethylene and oxygen is recycled to the plant. At this point, the chlorides in the recycle gas stream that need to be analyzed by gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com