Liquid density on-line monitoring system based on ultrasonic diffraction grating

A liquid density and ultrasonic technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of increased error, reduced quality of the characteristic curve of the sensor, reduced accuracy, etc., to achieve good system stability, fast data processing speed, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

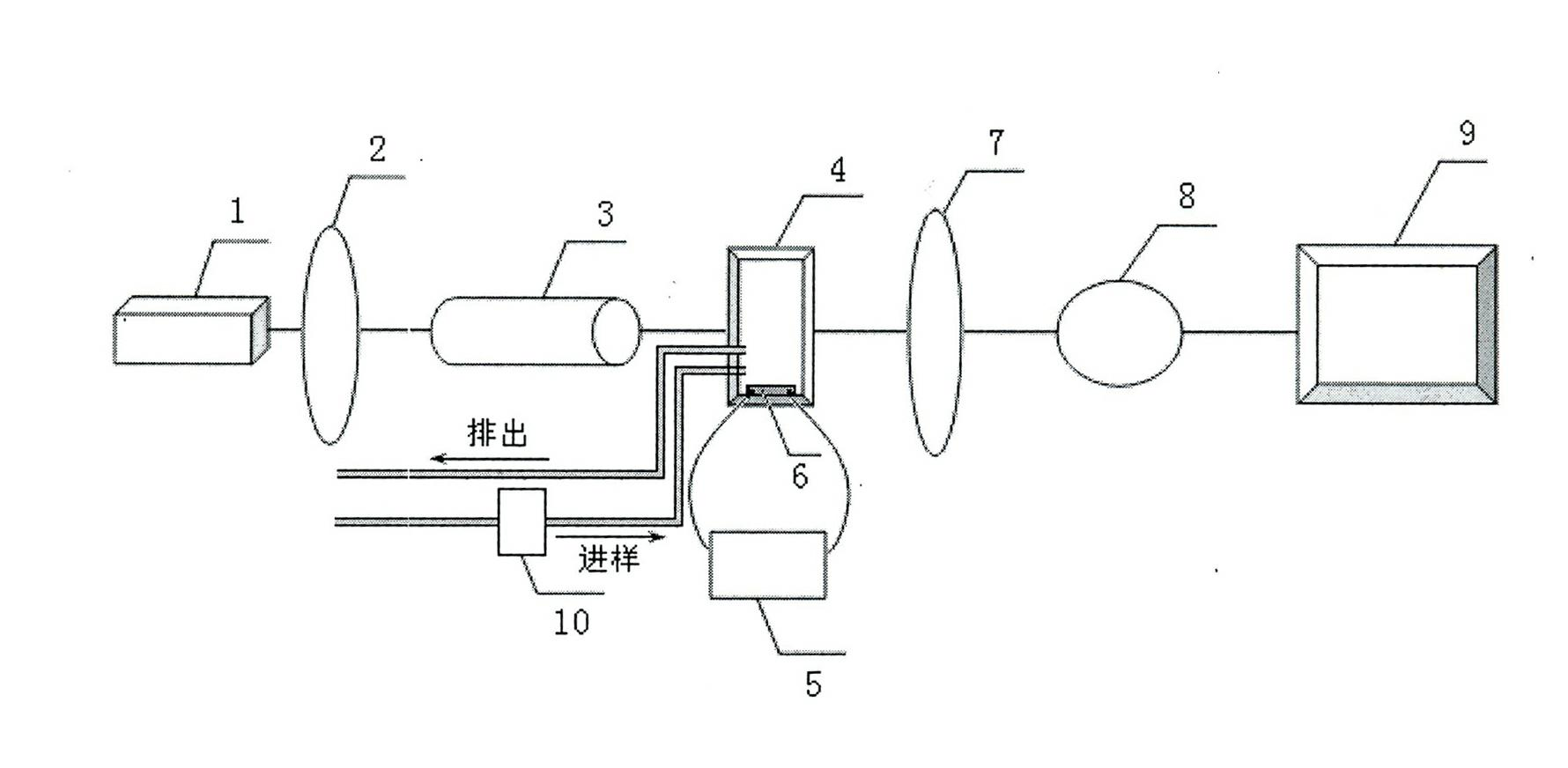

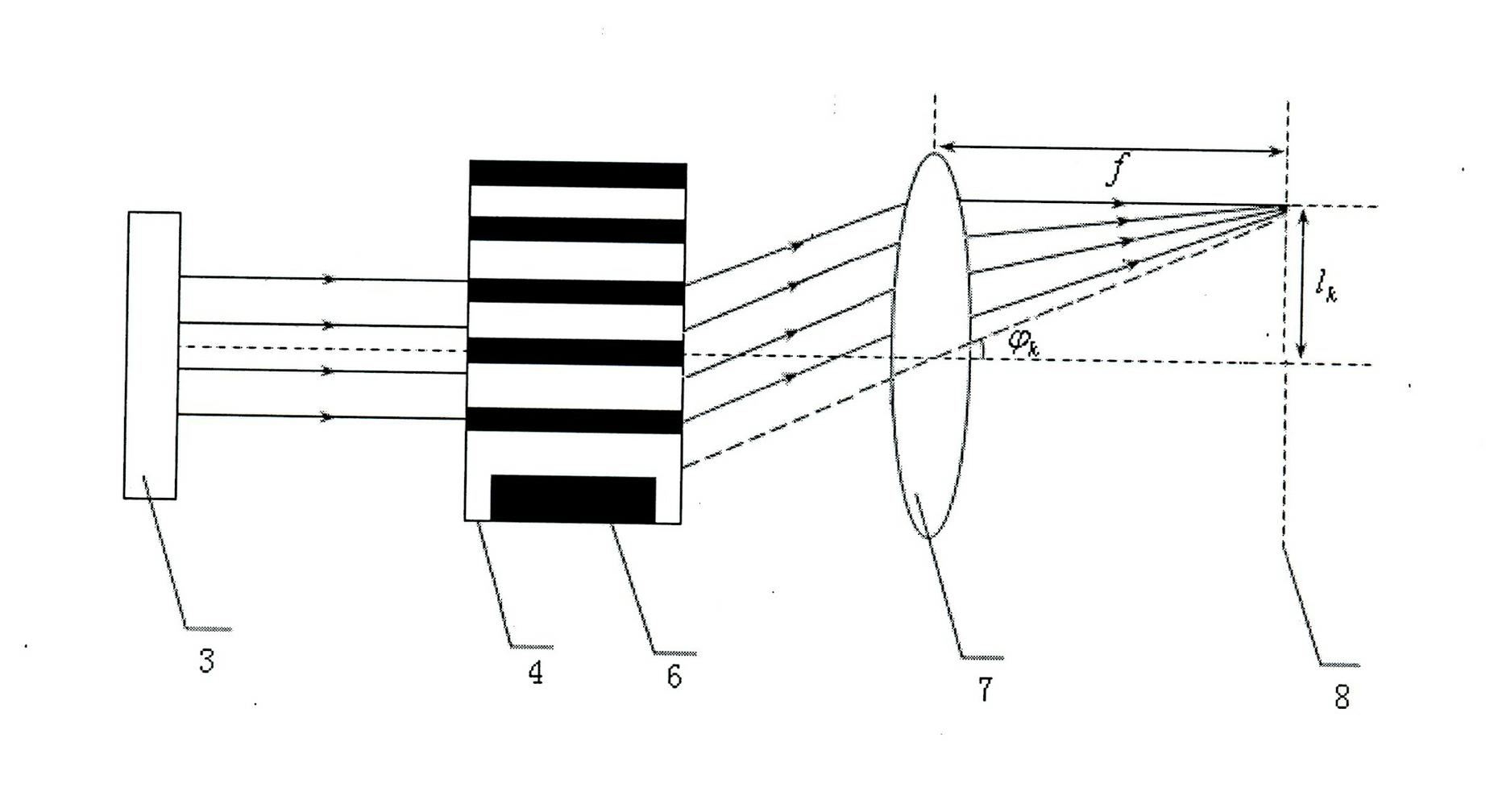

[0022] Such as figure 1 As shown, the on-line monitoring system of the liquid density based on the ultrasonic diffraction grating of the present invention includes a helium-neon laser (632.8nm) 1, and a semiconductor laser (600nm); a beam expander 2 and a collimator 3 are composed of A lens barrel structure composed of two convex lenses, the image focus of the front lens coincides with the object focus of the rear lens, and the front end is equipped with an adjustable slit; an ultrasonic pool 4 is a rectangular container with a cover made of quartz precision machining; A DDS ultrasonic signal source (DDS module) 5, a piezoelectric ceramic planar superradiation wave generator 6 uses a PZT chip; a converging lens 7, a linear array CCD detector 8, a computer 9 and a peristaltic pump 10; The beam mirror is placed in front of the laser, the collimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com