Forced circulation type hot water boiler structure

A hot water boiler and forced circulation technology, which is applied in the field of hot water boilers, can solve the problems of waste of metal consumption of the boiler body, increase the construction cost of the boiler room, etc., and achieve less incomplete combustion loss, lower height, and lower metal consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

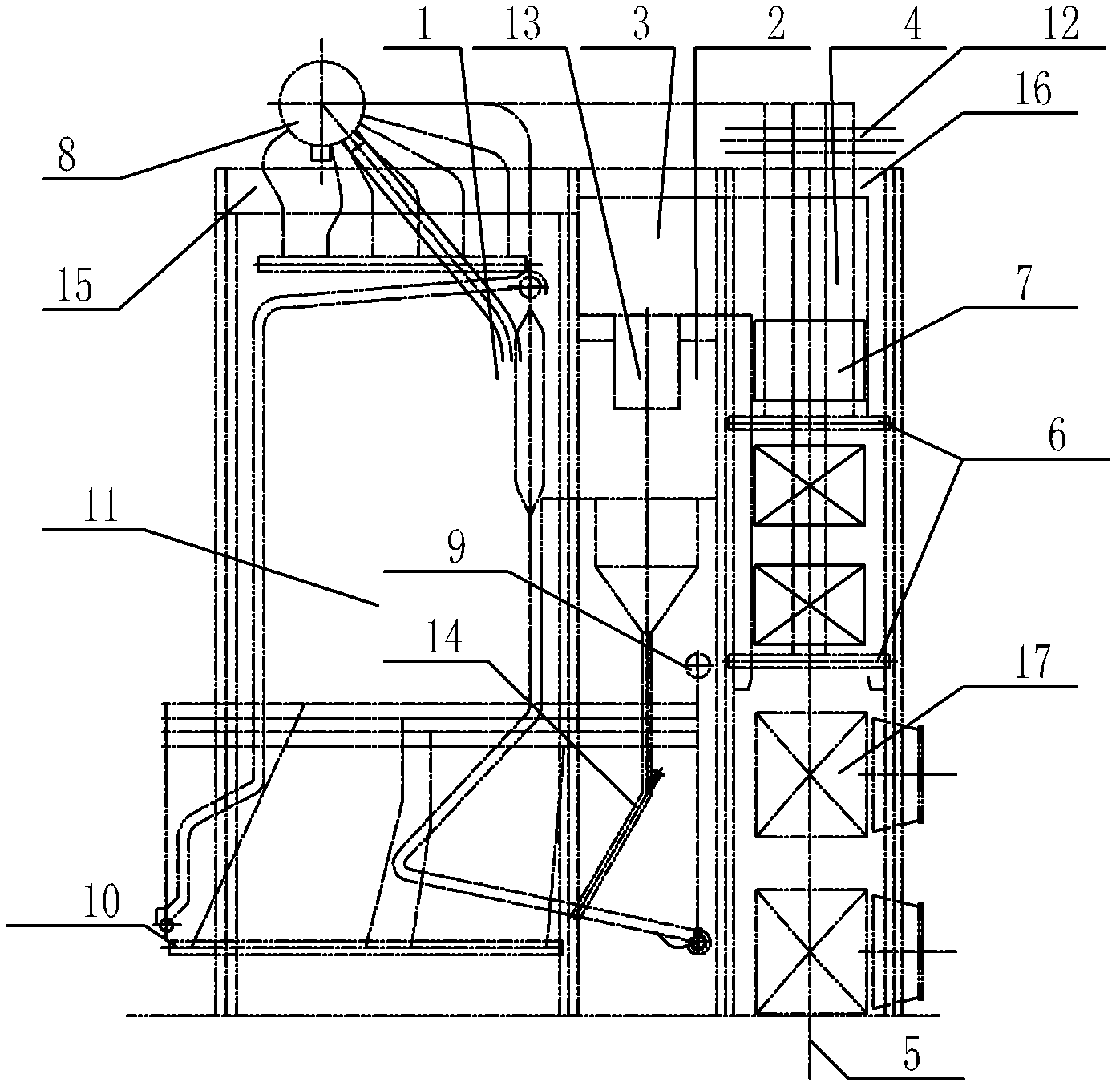

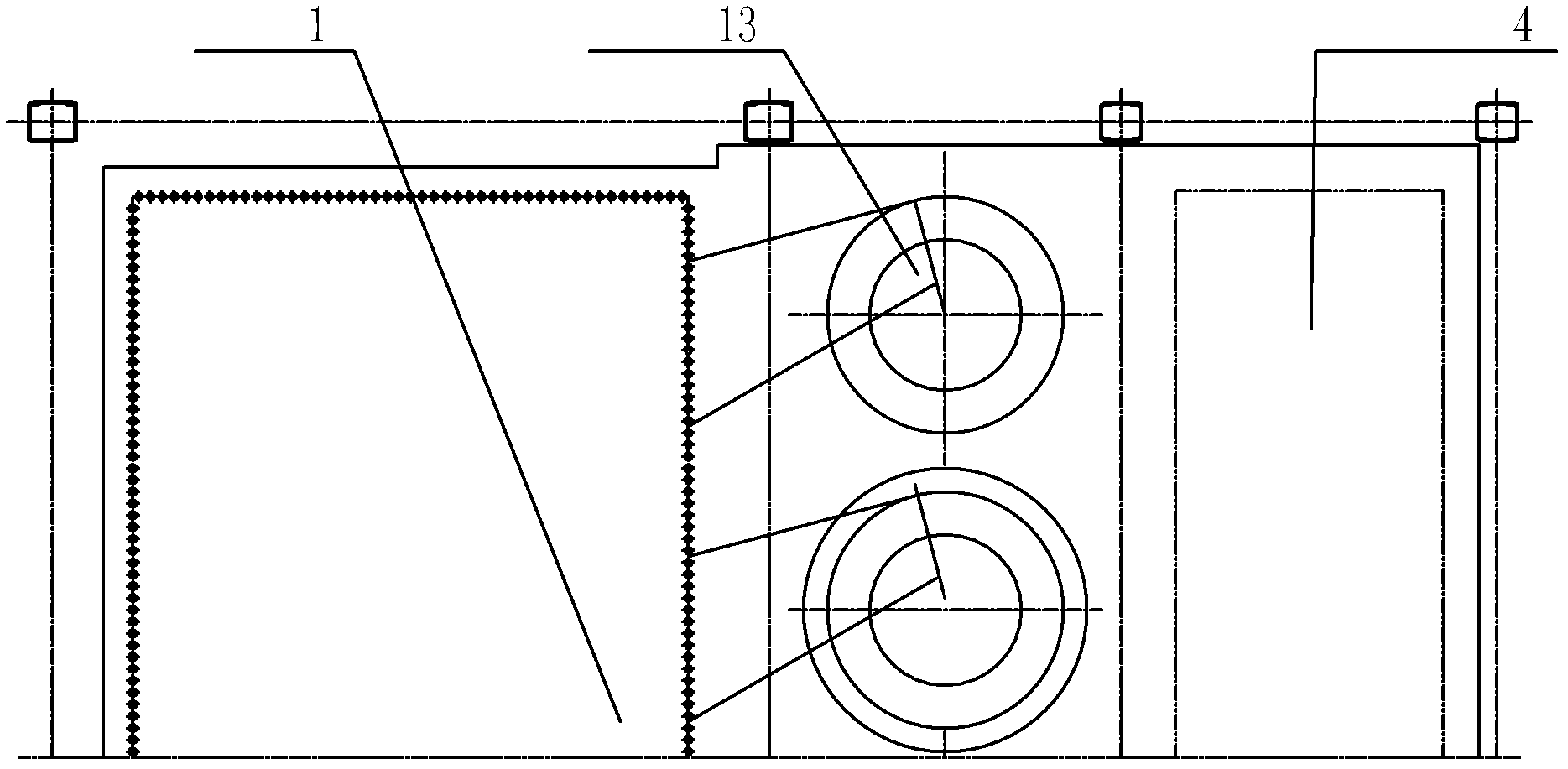

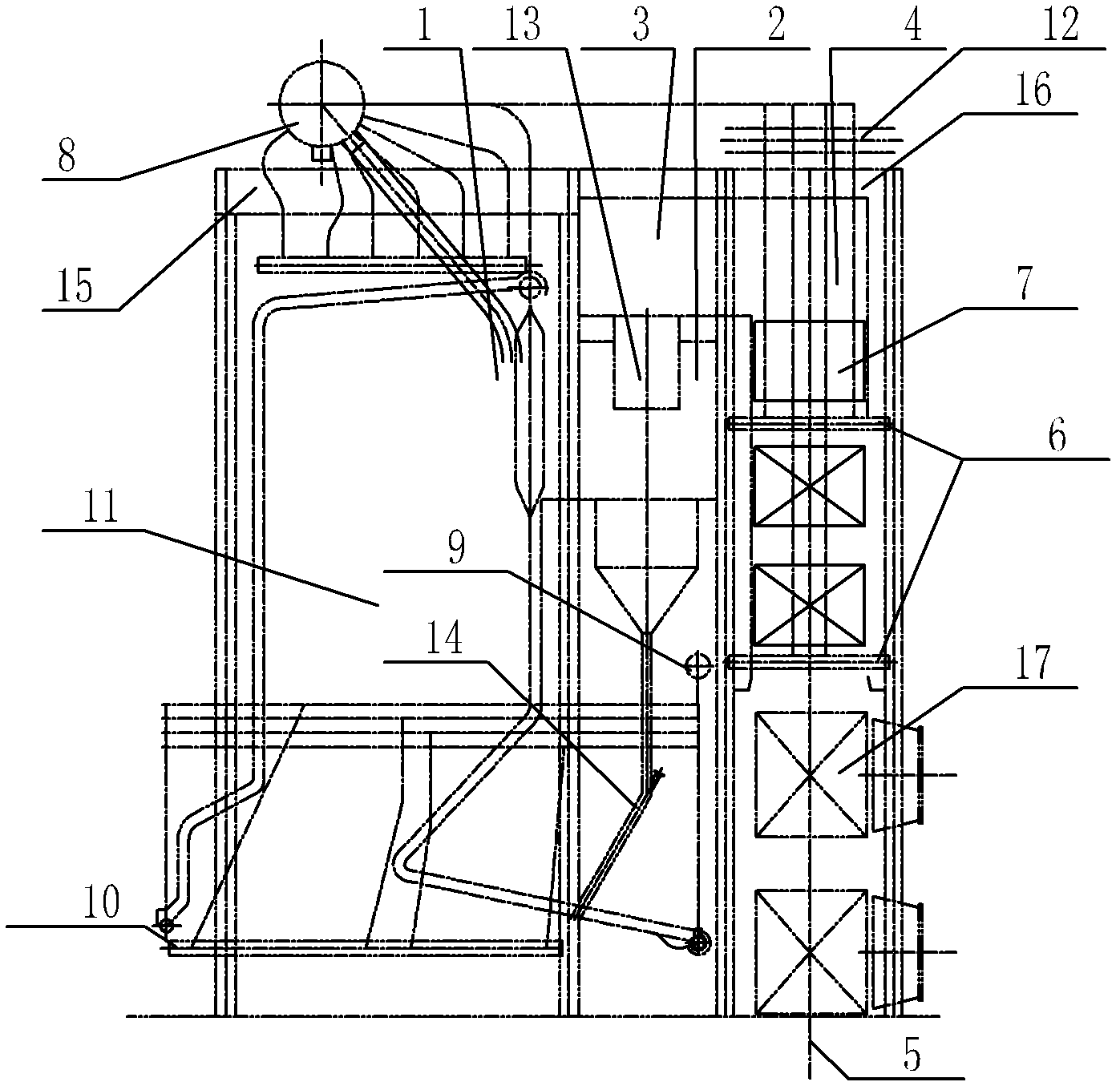

[0012] The present invention will be further described below in conjunction with specific drawings.

[0013] like Figure 1~Figure 2 Shown: The structure of the forced circulation hot water boiler includes furnace 1, cyclone separator 2, horizontal flue 3, tail shaft 4, flue gas outlet 5, economizer header 6, economizer 7, drum 8, return water Distribution header 9, water wall header 10, water wall 11, hot water outlet header 12, separator 13, fly ash backburning pipeline 14, front top plate 15, rear top plate 16, air preheater 17, etc.

[0014] The present invention comprises a furnace 1, a cyclone separator 2 is arranged at the outlet of the furnace 1, the outlet end of the cyclone separator 2 communicates with a horizontal flue 3, a tail shaft 4 is arranged on one side of the horizontal flue 3, and a tail shaft 4 is arranged on the tail shaft 4 An economizer 7 is installed in the center, an air preheater 17 is installed at the bottom of the tail shaft 4, and the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com