System and process for treating water tank water of printing plant and CTP plate flushing water to reach discharge standard

A discharge standard and printing factory technology, applied in the direction of filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of failing to meet the sewage discharge requirements, and achieve secondary pollution, stable equipment operation, and metal consumption low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

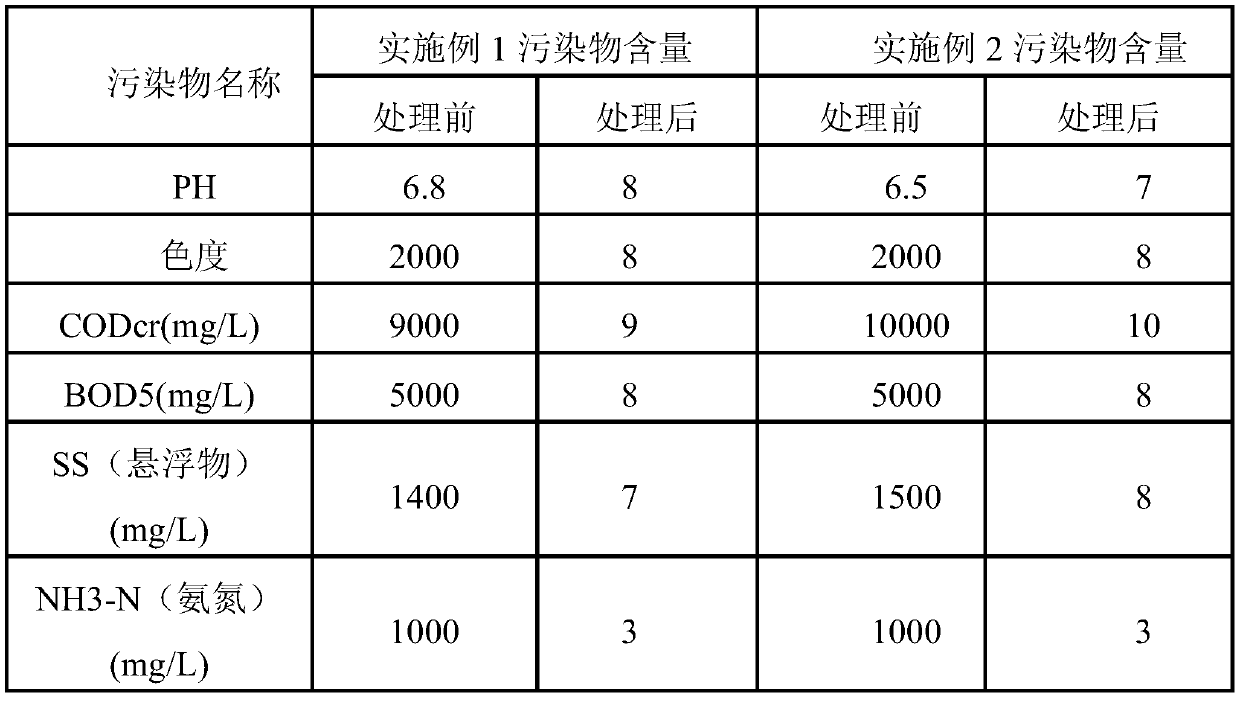

Embodiment 1

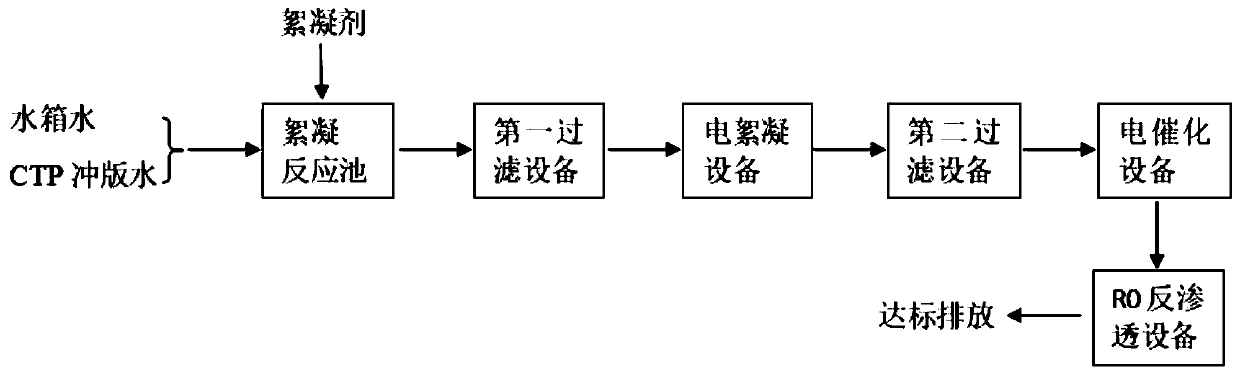

[0052] Such as figure 1 As shown, a system for treating water tank water in a printing factory and CTP flushing water to meet discharge standards in this embodiment, the system includes sequentially connected flocculation reaction pools, a first filter device, an electroflocculation device, a second Two filter equipment, electrocatalysis equipment and RO reverse osmosis equipment; the stirring equipment is fixedly arranged in the described flocculation reaction pool; the described flocculation reaction pool is connected with the first filter equipment through a sewage pump; the electroflocculation equipment The cathode and the anode are both aluminum plates; the electrocatalytic equipment includes the anode, the cathode and the electrocatalytic oxidation filler filled between the two; the electrocatalytic equipment used in this sewage treatment system is as shown in the patent CN110734114A, including the anode ( carbon plate), the cathode (carbon plate) and the electrocatalyti...

Embodiment 2

[0055] Such as figure 1 As shown, a system for treating water tank water in a printing factory and CTP flushing water to meet discharge standards in this embodiment, the system includes sequentially connected flocculation reaction pools, a first filter device, an electroflocculation device, a second Two filter equipment, electrocatalysis equipment and RO reverse osmosis equipment; the stirring equipment is fixedly arranged in the described flocculation reaction pool; the described flocculation reaction pool is connected with the first filter equipment through a sewage pump; the electroflocculation equipment The cathode and the anode are both aluminum plates; the electrocatalytic equipment includes an anode, a cathode and an electrocatalytic oxidation filler filled between the two; the electrocatalytic equipment adopted in this sewage treatment system includes an anode (carbon plate), a cathode (carbon plate) and the electrocatalytic oxidation filler filled between them.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com