Metal silencing hood for pipeline of petrochemical device

A petrochemical device and sound insulation cover technology, which is applied in the direction of metal layered products, pipe components, chemical instruments and methods, etc., can solve the problems of petrochemical pipeline sound insulation measures, noise hidden dangers in the plant, etc., and improve the overall sealing performance of the sound insulation cover Overall, good sound absorption performance, easy disassembly and reinstallation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

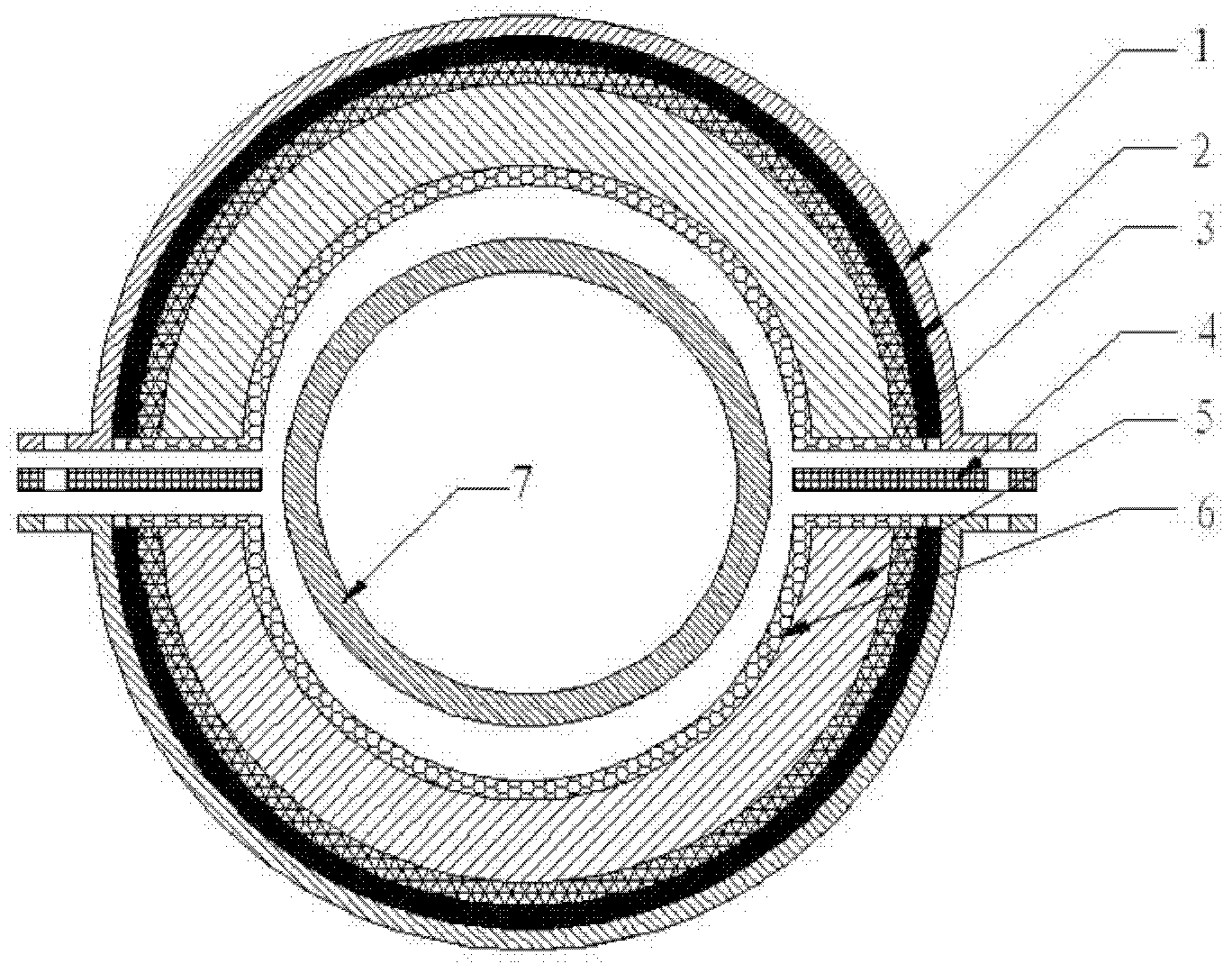

[0029] Such as Figure 1 to Figure 3 As shown, 1.5mm thick 316 stainless steel is selected as the sound insulation board 1, which is processed into a semicircular shell by stamping, and the surface density of 1.5mm thick 316 stainless steel is 11.7g / cm 2 , so its sound insulation is about 24.3dB(A). Next, the damping material 2 is coated on the inner wall of the stainless steel sound insulation board 1, and the thickness of the damping layer is about 0.5 mm. Then pave 316 stainless steel fiber mat 3 on the inner wall of the shell, with a pore size of 20 μm, a porosity of 85%, and good flame retardancy. After the stainless steel fiber mat 3 is installed, add glass fiber sound-absorbing material 5, the thickness of the glass fiber sound-absorbing material is about 50mm, and the density is 200g / cm 3 , the average sound absorption coefficient is 0.75. In order to fix the sound-absorbing material and fiber felt in the sound insulation shell. When the sound insulation cover 9 is...

Embodiment 2

[0031] Such as Figure 1 to Figure 3 As shown, a 2mm thick galvanized iron sheet is selected as the sound insulation board 1, which is processed into a semicircular shell by stamping, and the surface density of the 2mm thick galvanized iron sheet is 15.6g / cm 2 , so its sound insulation is about 30dB(A). Next, the damping material 2 is coated on the inner wall of the stainless steel sound insulation board 1, and the thickness of the damping layer is about 1 mm. Then pave 316 stainless steel fiber mat 3 on the inner wall of the shell, with a pore size of 20 μm, a porosity of 85%, and good flame retardancy. After the stainless steel fiber felt 3 is installed, add the fiber sound-absorbing material 5 rock wool, the thickness of the rock wool sound-absorbing material is about 60mm, and the density is 240g / cm 3 , the average sound absorption coefficient is 0.80. In order to fix the sound-absorbing material and fiber felt in the sound-insulating shell, the metal protective perfora...

Embodiment 3

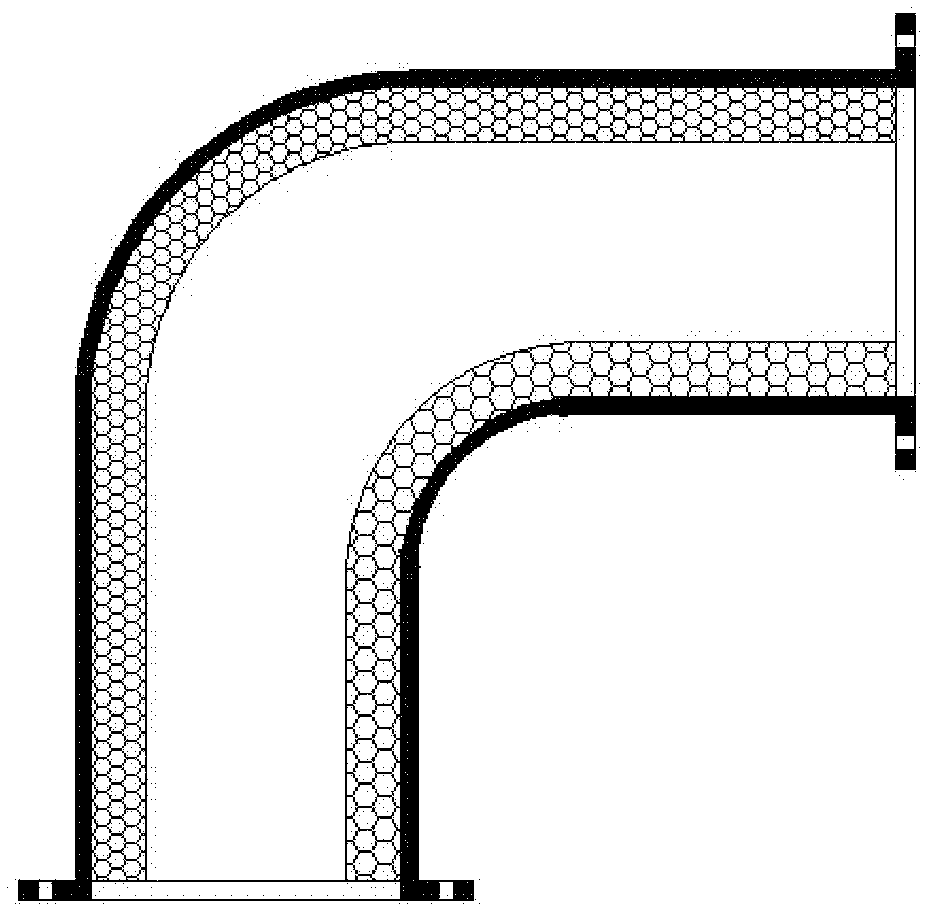

[0033] Such as Figure 1 to Figure 3 As shown, a 2mm thick galvanized iron sheet is selected as the sound insulation board 1, which is processed into a semicircular curved pipe shell by stamping, and the surface density of the 2mm thick galvanized iron sheet is 15.6g / cm 2 , so its sound insulation is about 30dB(A). Next, the damping material 2 is coated on the inner wall of the stainless steel sound insulation board 1, and the thickness of the damping layer is about 1 mm. Then pave 316 stainless steel fiber mat 3 on the inner wall of the shell, with a pore size of 25 μm, a porosity of 80%, and good flame retardancy. After the stainless steel fiber felt 3 is installed, add the fiber sound-absorbing material 5 rock wool, the thickness of the rock wool sound-absorbing material is about 60mm, and the density is 240g / cm 3 , the average sound absorption coefficient is 0.80. In order to fix the sound-absorbing material and fiber felt in the sound-insulating shell, the metal protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com