Gas column band type gas spring

A technology of air spring and air column, which is applied in the field of spring manufacturing, can solve the problems of complex structure, high requirements for parts matching, and low compressive strength, and achieve the effects of good horizontal and vertical ventilation, overcoming complex structure, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

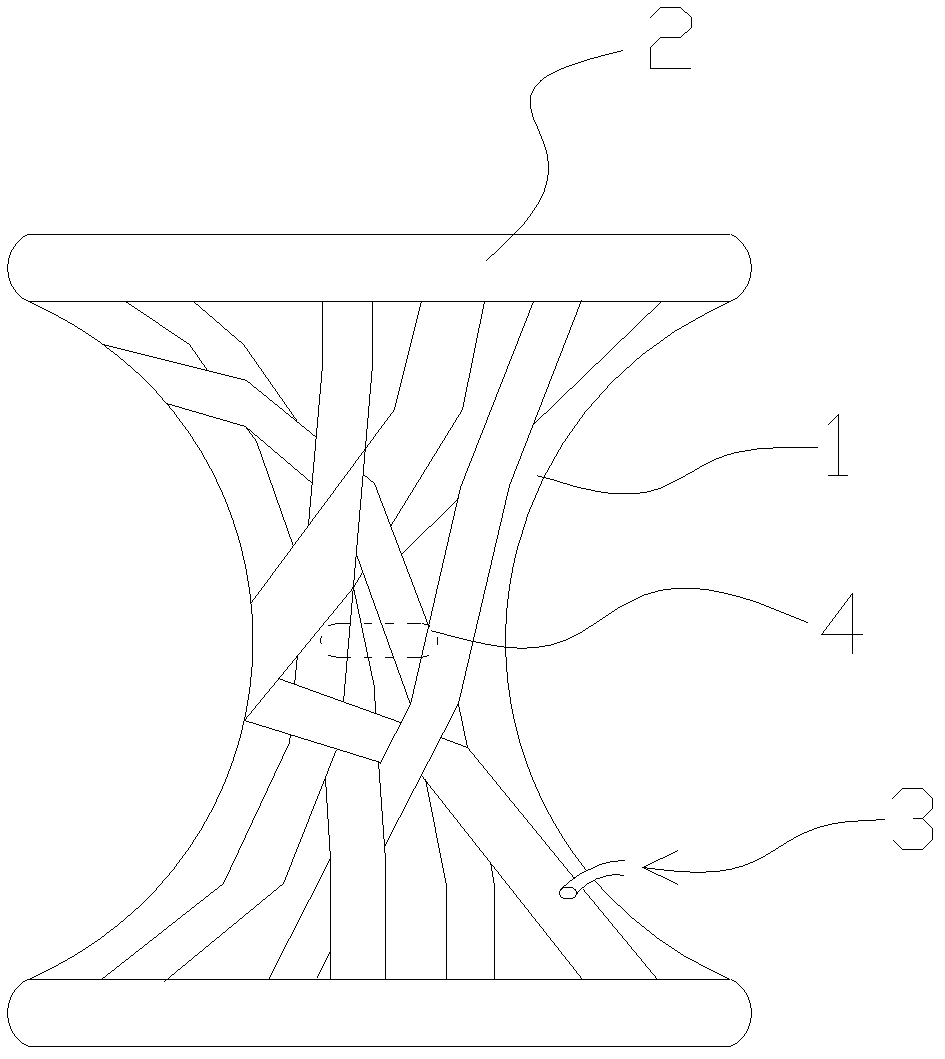

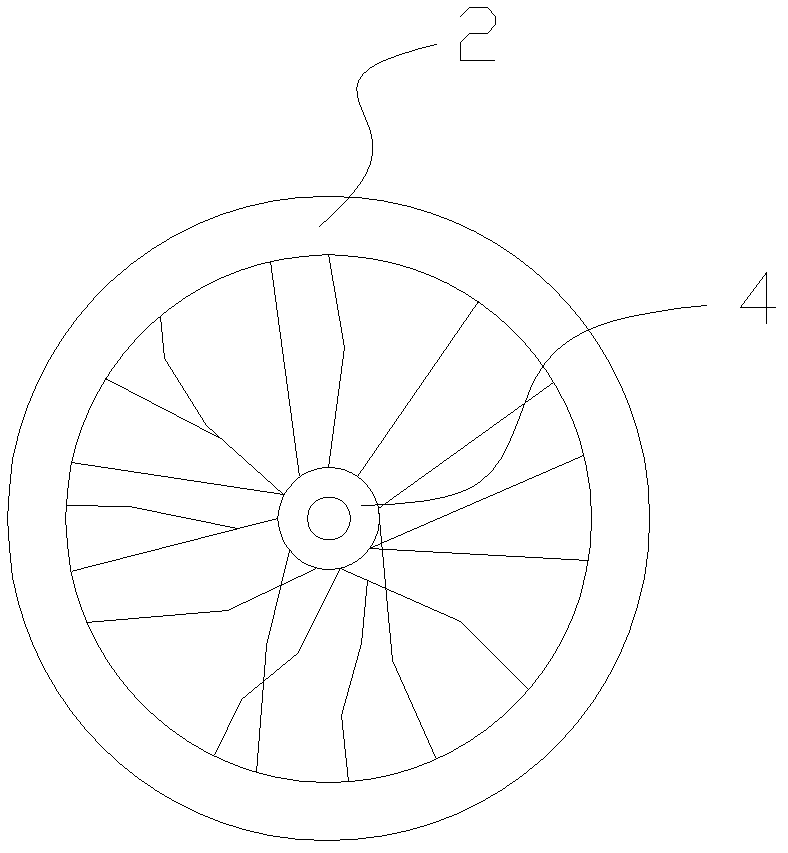

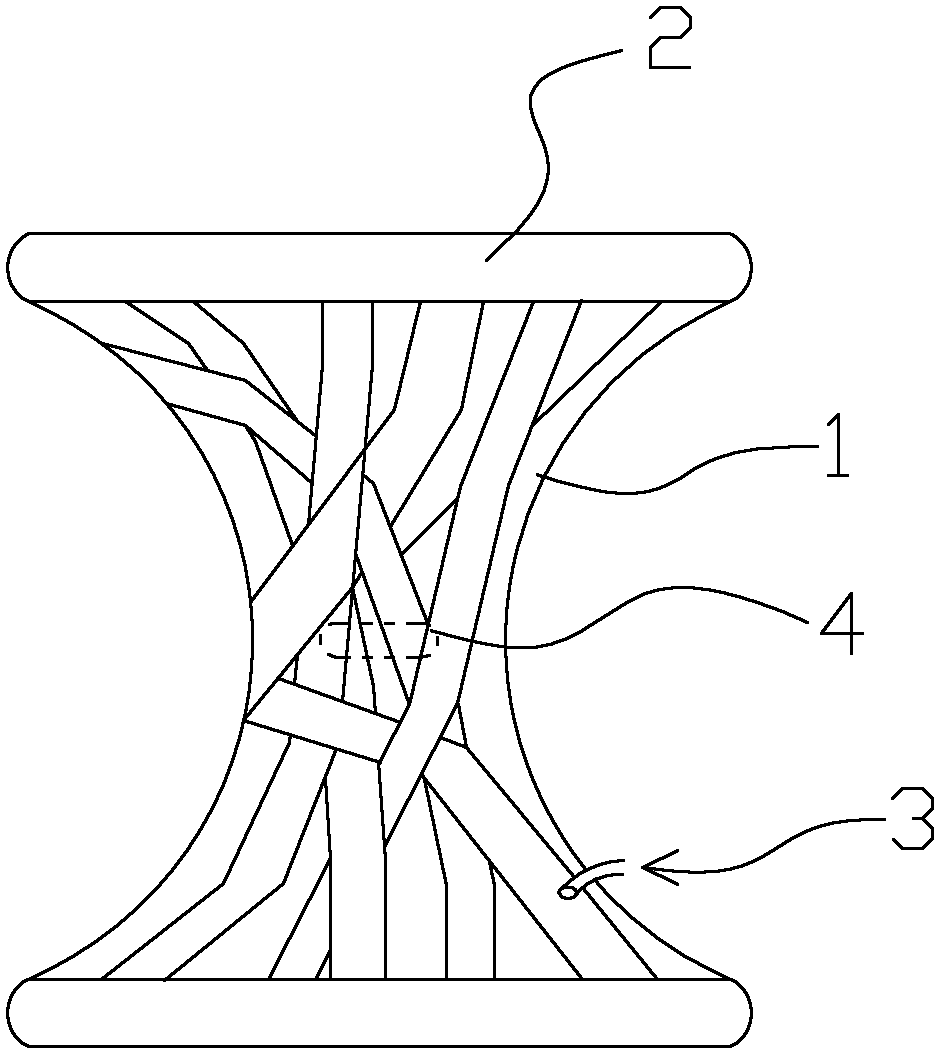

[0021] Such as figure 1 , figure 2 As shown, the present invention describes a kind of gas column band type air spring, which includes a spring body, and the spring body is composed of a plurality of gas column bands 1 with pressure gas accommodation chambers, and the plurality of gas column bands 1 are straight The strip is shaped and connected to a positioning piece 2 at the upper and lower ends respectively, the gas pressure in the containing cavity can be adjusted, and the air pressure adjustment can be realized through the ventilation device. The air column strips 1 in this embodiment communicate with each other and have a vent hole 3 communicating with the containing chamber. There may also be two vent holes 3, one for inflation and one for exhaust. The plurality of air column strips 1 are arranged vertically and leave transverse and longitudinal ventilating passages between them. The air column band 1 is lined with a hard ring 4 to prevent damage caused by uneven for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com