Siphon air cooling thermal power generation device

A thermal power generation and air-cooling technology, applied in steam engine installations, machines/engines, lighting and heating equipment, etc., can solve the problems of increasing investment and recurring costs, increasing the difficulty of site selection for construction sites, and large water consumption. The effect of water treatment, reduction of usage, lower investment and site selection conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

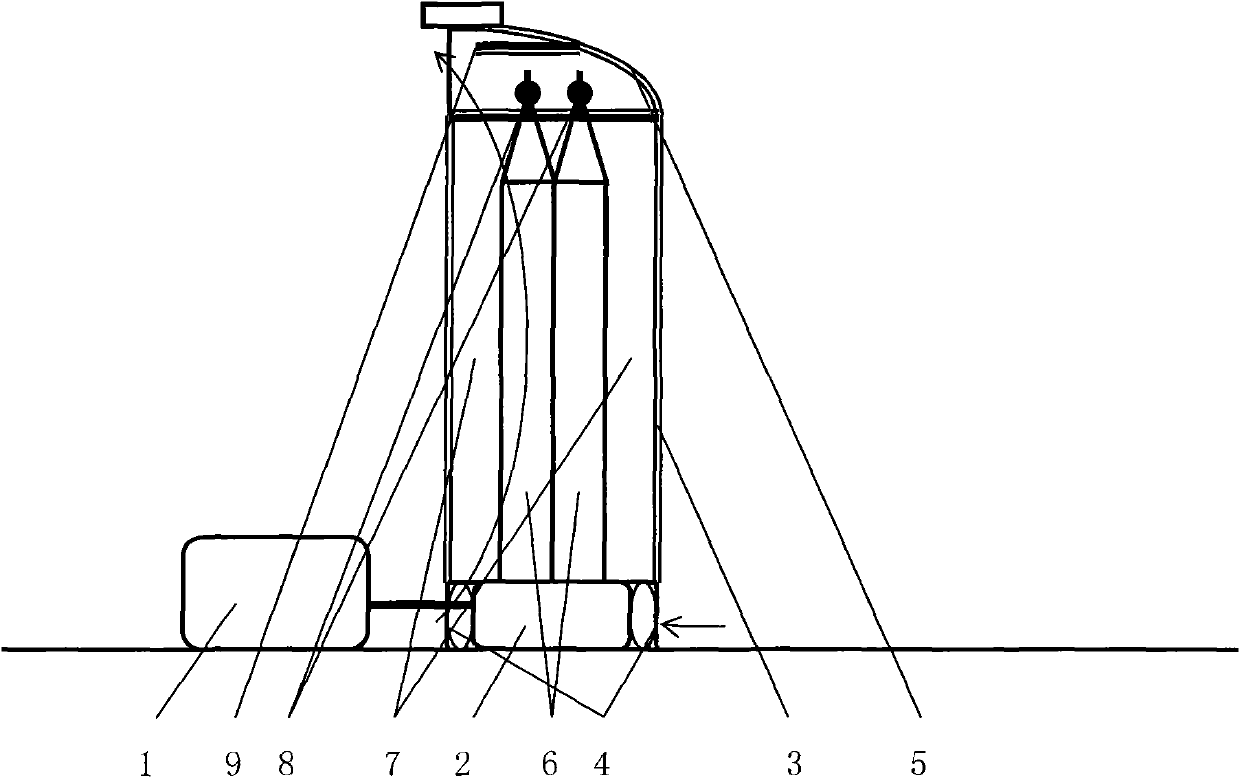

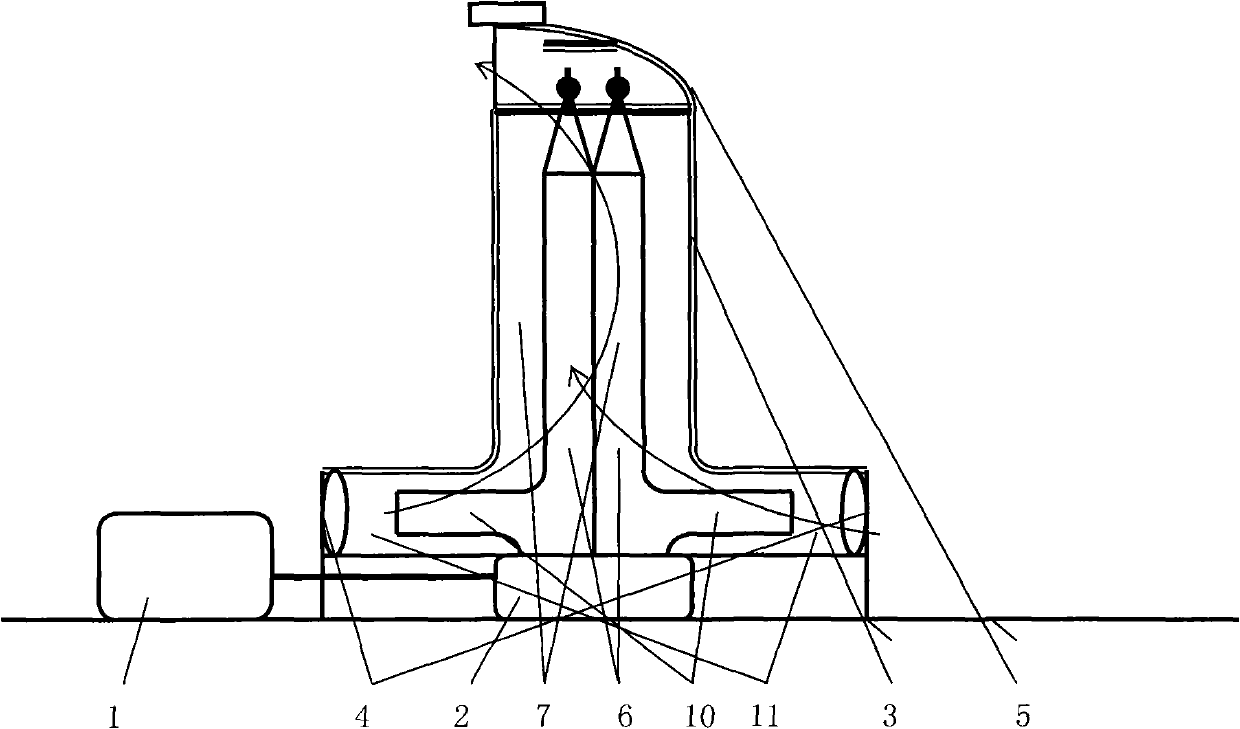

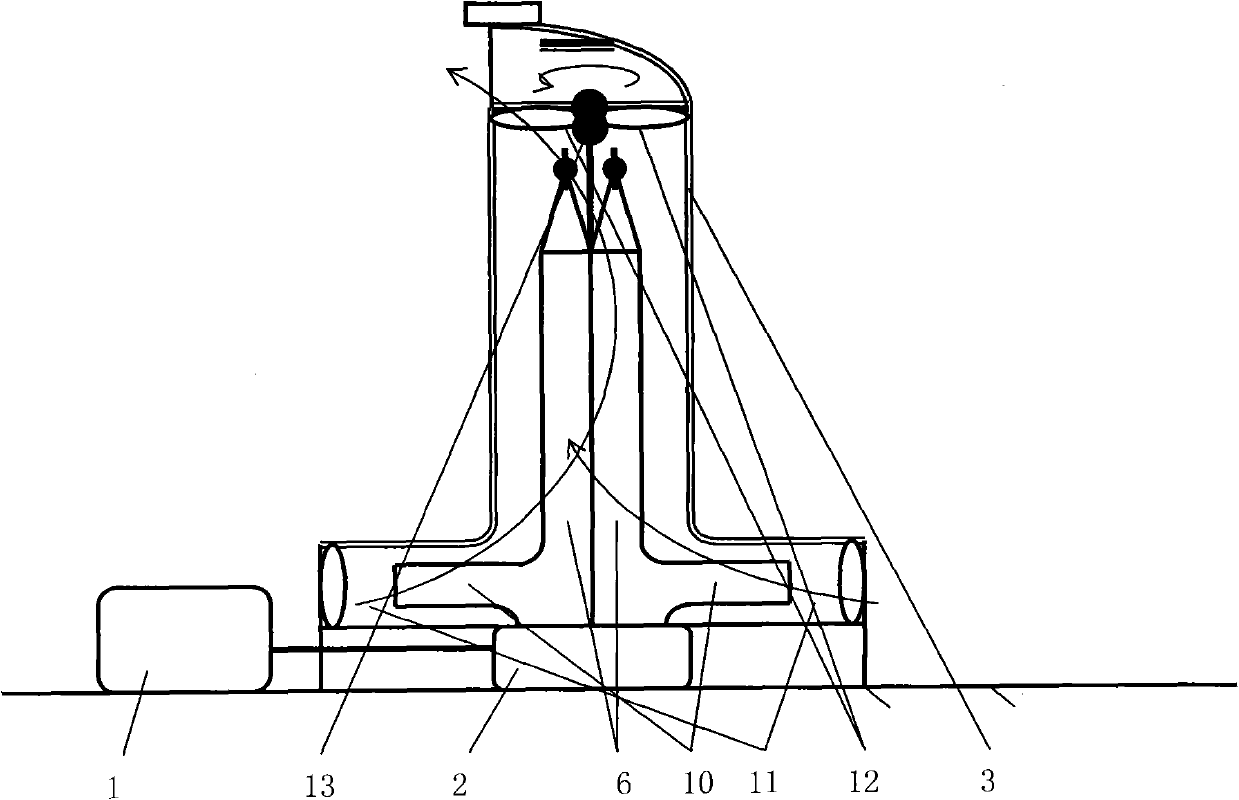

[0019] figure 1 An example of the present invention is given. figure 1 Among them, a siphon air-cooled thermal power generation device is composed of a steam boiler 1, a steam turbine 2, a generator and a cylindrical condenser 3. The air inlet channel 4 is set at the bottom of the cylindrical condenser 3, and a side air outlet 5 is connected with a rotating pair at the upper end of the cylindrical condenser 3 as an air outlet channel; the exhaust steam condenser 6 of the thermal power generation device is placed in the cylindrical in condenser 3. The air inlet passage 4—the interior of the tubular condenser 3—the air outlet form a low wind resistance air passage 7.

[0020] An automatic valve 8 is set at the top of the exhaust steam condenser 6 . Connecting the outer end of the automatic valve 8 with a negative pressure source and opening the automatic valve 8 can remove the non-condensable gas in the steam turbine 2 .

[0021] figure 1 The working principle of the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com