Integrated axial-flow fan

A technology for axial flow fans and casings, applied in axial flow pumps, liquid fuel engines, cooling/ventilation devices, etc., can solve problems such as poor heat dissipation, reduced volume and quality of fans, serious heat generation of motors, etc., to reduce impeller The effect of reducing the diameter, reducing the volume of the fan, and reducing the weight of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

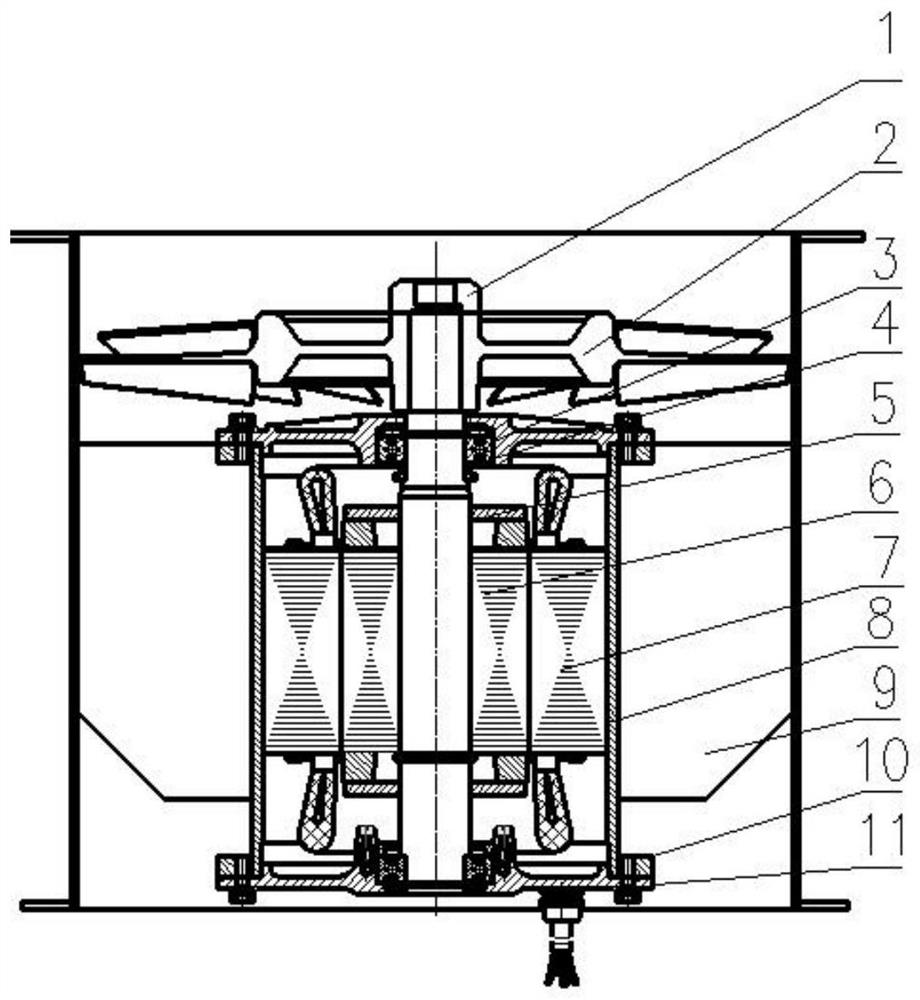

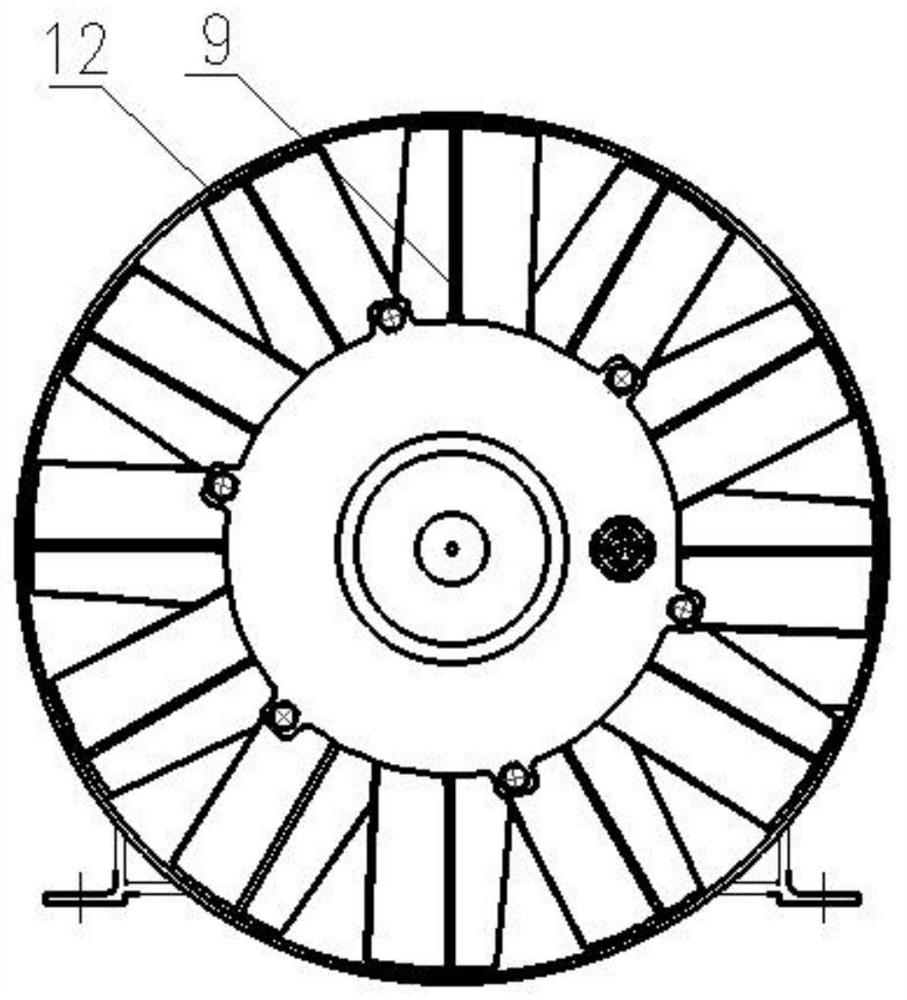

[0026] see figure 1 and figure 2 , an integrated axial flow fan, including a casing, a motor and an impeller 2, the casing includes an inner air cylinder 8, an outer air cylinder 12 and guide vanes 9, and the inner air cylinder 8 and the outer air cylinder 12 are the same The axis is sleeved and the two are connected by guide vanes 9. An airflow channel is formed between the inner air cylinder 8 and the outer air cylinder 12. The motor is arranged on the inner air cylinder 8 and the two are coaxial. The motor The output shaft of the motor is connected to the impeller 2; the maximum rotating speed of the motor is 8800r / min, and the motor is a variable frequency motor.

[0027] Preferably, the inner air cylinder 8, the outer air cylinder 12 and the guide vanes 9 are integrally formed (that is, the three are integrated), the integral formation is conducive to shortening the heat conduction path of the motor, and the heat of the motor is directly transferred to the guide vanes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com