Cable tunnel routing inspection robot

A technology for inspection robots and cable tunnels, applied in instruments, scientific instruments, closed-circuit television systems, etc., can solve problems such as inability to observe at close range, limited range of activities, and manual charging, and is suitable for unmanned operation and solves manual charging , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

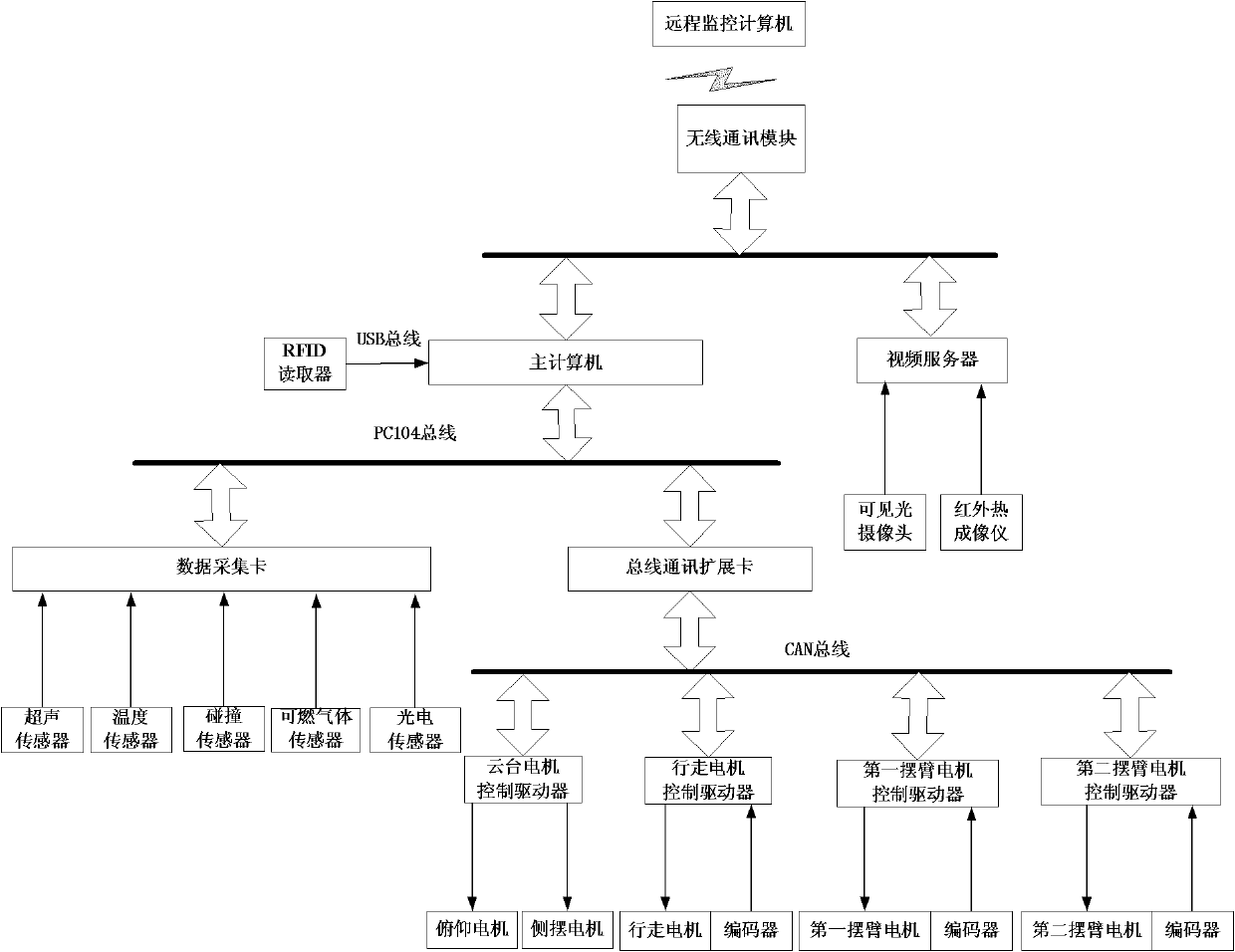

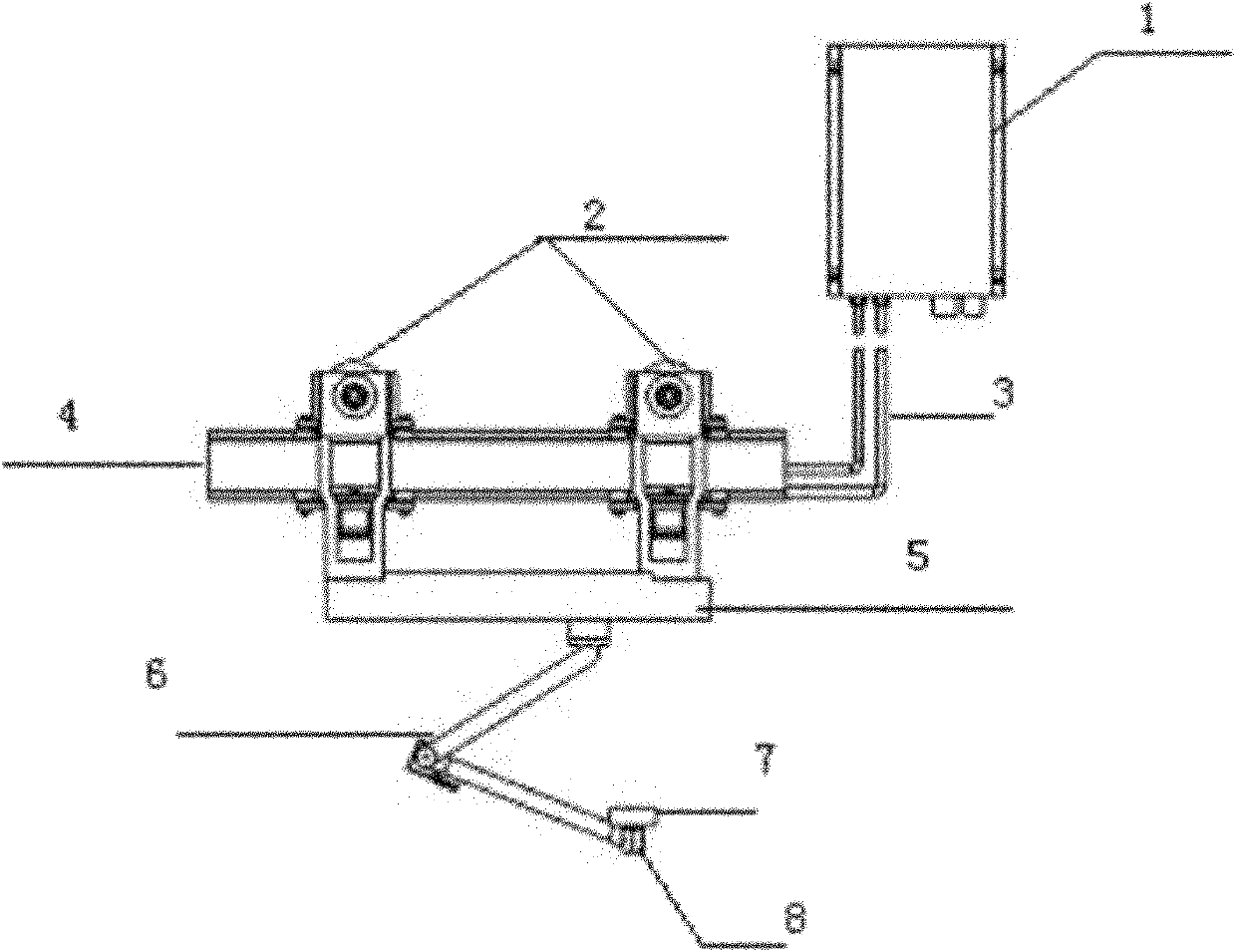

[0025] Cable tunnel inspection robot of the present invention, such as figure 1 As shown, it includes a robot body 5, an autonomous mobile device 2 and a mechanical arm 6, wherein an autonomous mobile device 2 is installed on the robot body 5, and the autonomous mobile device 2 is suspended and installed on a track 4 and moves along the track 4; the mechanical arm 6 is installed On the robot body 5, the end of the mechanical arm 6 is provided with a pan platform 8; the robot body 5 is provided with a control device and a power supply device, and the power supply device is inductively electrically connected to the cable 3 connected to the external power supply cabinet.

[0026] Autonomous mobile device 2 comprises a driving wheel and a driven wheel, and driving wheel and driven wheel are located on track 4 rail surface, and robot body 5 is suspended and installed on track 4 and the opposite side of rail surface by connector.

[0027] The control part of the autonomous mobile de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com