Guidance type waterproof thermal insulation system

A technology of drainage system and heat insulation board, applied in the direction of roof insulation material, roof drainage, roof, etc., can solve the problems of waste of resources, large resource consumption, not long, etc., to reduce construction difficulty, improve heat insulation effect, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

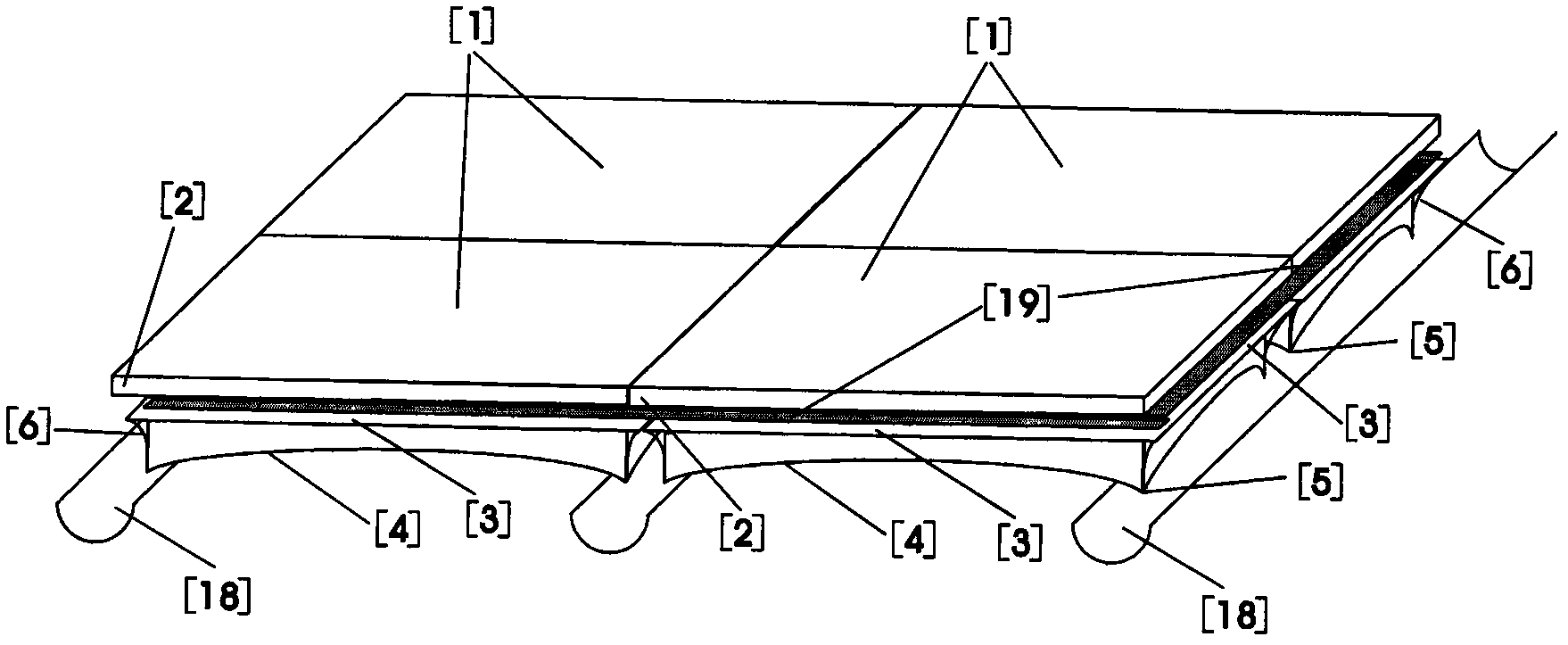

[0036] Example 1: Combining figure 1 , 2 , respectively make a male interface [2] and a female interface [3] on the upper adjacent (or opposite) sides of the heat shield [1] (or make the male interface [2] or female interface [3] at the same time on the four sides), The lower edge of the lower part of the heat shield (that is, the skirt) is processed into a smooth arc diversion curve with low ends and a high middle [4], and a smooth diversion surface is processed at the joint between the male and female interfaces and the skirt (or inclined plane) [6], the foot [7] of insulation board is made in the suitable position of four angles in the skirt. When installing heat shields, align the lowest points [5] of the curved diversion curves [4] of the skirts of each row (or row) of heat shields (that is, line them up in a straight line), and use anti-aging and energy-saving Appropriately deformed waterstops, (waterproof) concrete, sediment (preferably surface hydrophobic treatment),...

Embodiment 2

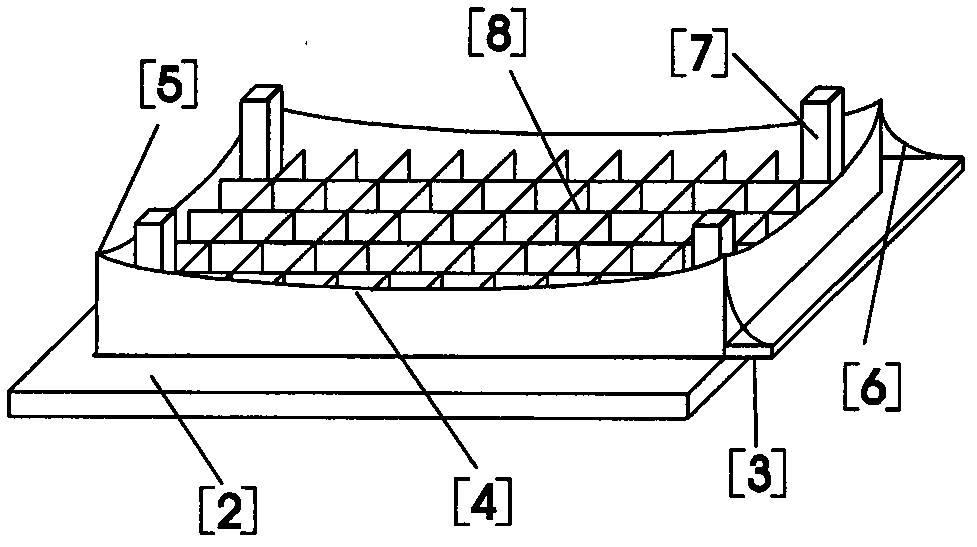

[0037] Example 2: Combining image 3 , it is on the basis of Example 1, adding an appropriate amount of grid-like ribs [8] in the skirt of the heat insulation board to divide it into multiple small squares to improve the strength and bearing capacity of the heat insulation board.

Embodiment 3

[0038] Example 3: Binding Figure 4 , it is on the basis of embodiment 2, and the top of small square is processed into spherical, arc or ∧ shape diversion curved surface or slope, and the lower edge of grid-like edge is processed into grid-shaped arc diversion curve [ 8], which can not only improve the strength and bearing capacity of the heat insulation board, but also when the heat insulation board cracks, the spherical, arc-shaped or ∧-shaped diversion curved surface or slope at the top of each small square will seep from the crack The leaked rainwater first flows to the grid-shaped arc-shaped diversion curve [8], and then is diverted by the grid-shaped arc-shaped diversion curve [8] and the arc-shaped diversion curve [4] to a suitable slope or gradient. In the U-shaped water collection and diversion groove [18], the waterproof task is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com