Vacuum coating piece and manufacturing method of vacuum coating piece

A vacuum coating and manufacturing method technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of limited color of metal vacuum coating layer, limited competitiveness in the field of decorative coating, difficult precision control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) pre-coating treatment

[0032] The substrate 11 was ultrasonically cleaned with acetone for about 5 minutes.

[0033] Put the cleaned substrate 11 into the turntable in the coating chamber of the magnetron sputtering coating machine. The surface of the substrate 11 is cleaned with argon plasma. Vacuumize the coating chamber to a vacuum degree of 3×10 -5 Torr, the flow rate of argon gas is 500sscm, the bias voltage applied to the substrate is -150V, and the plasma cleaning time is 10min. The magnetron sputtering coating machine used in this embodiment is produced by Nanfang Innovation Company, and the model is SM-1100H-D.

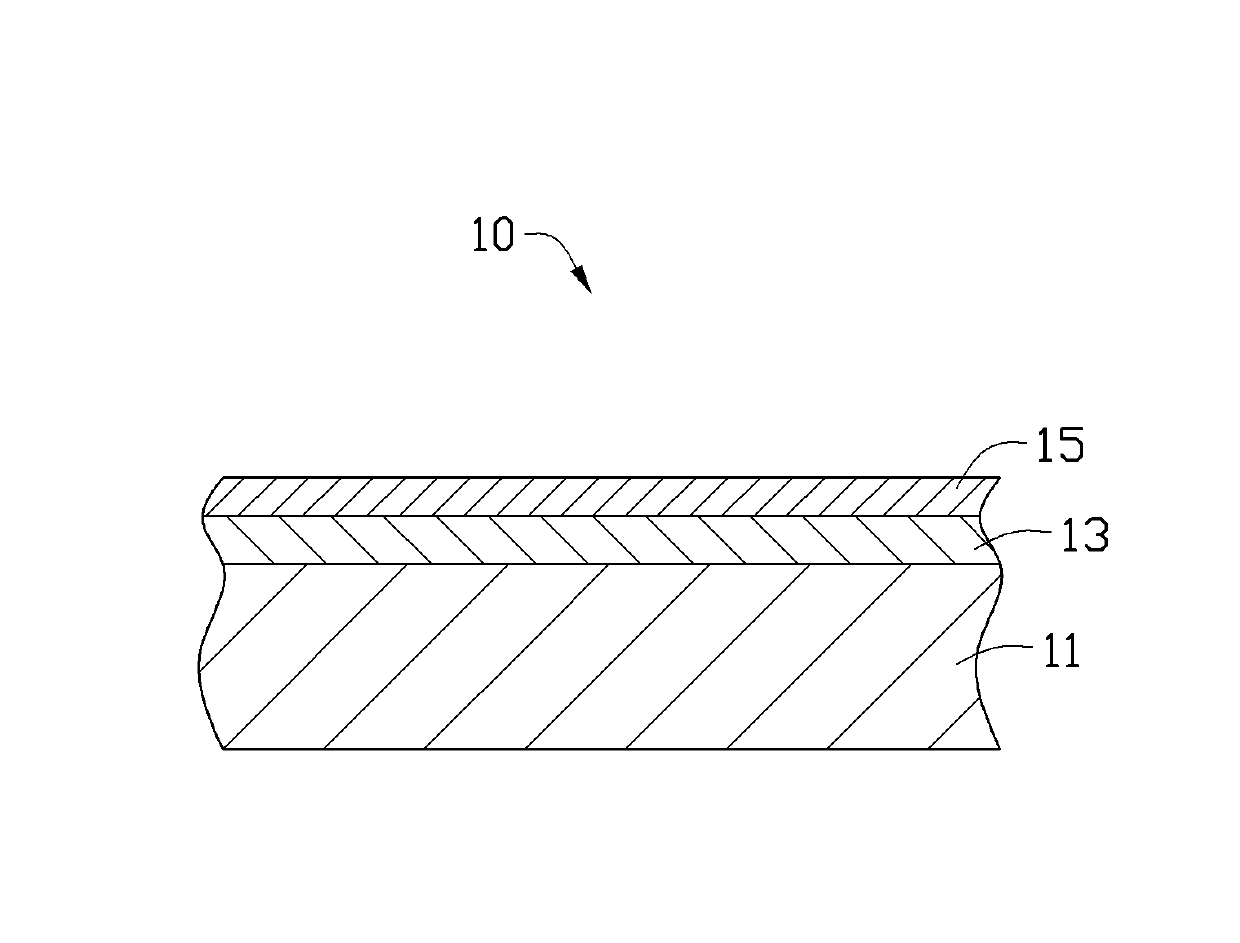

[0034] (2) Magnetron sputtering forms bonding layer 13

[0035] After the plasma cleaning is completed, use argon as the working gas, adjust its flow rate to 280 sccm, heat the coating chamber to 100°C, turn on the power supply of the aluminum target that has been placed in the magnetron sputtering coating machine, and set its power 8kw, a bi...

Embodiment 2

[0040] (1) pre-coating treatment

[0041] The substrate 11 was ultrasonically cleaned with acetone for about 5 minutes.

[0042]Put the cleaned substrate 11 into the turntable in the coating chamber of the magnetron sputtering coating machine. The surface of the substrate 11 is cleaned with argon plasma. Vacuumize the coating chamber to a vacuum degree of 3×10 -5 Torr, the flow rate of argon gas is 500sscm, the bias voltage applied to the substrate is -200V, and the plasma cleaning time is 10min. The magnetron sputtering coating machine used in this embodiment is produced by Nanfang Innovation Company, and the model is SM-1100H-D.

[0043] (2) Magnetron sputtering forms bonding layer 13

[0044] After the plasma cleaning is completed, use argon as the working gas, adjust its flow rate to 320 sccm, heat the coating chamber to 150° C., turn on the power supply of the aluminum target that has been placed in the magnetron sputtering coating machine, and set its power A bias v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com