Ester-producing yeast and method for producing acetic ether and alcohol by using same

A technology of ester-producing yeast and fermentation medium, applied in the preparation of alcoholic beverages, fungi, etc., can solve the problems of backward technology and difficulty in increasing the content of aroma components in wine, and achieve low production investment, full-bodied wine, and high profitability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

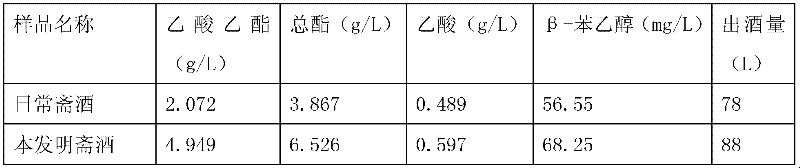

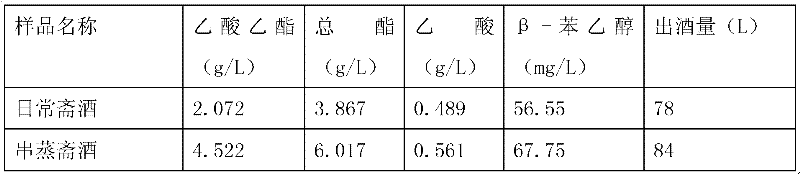

Examples

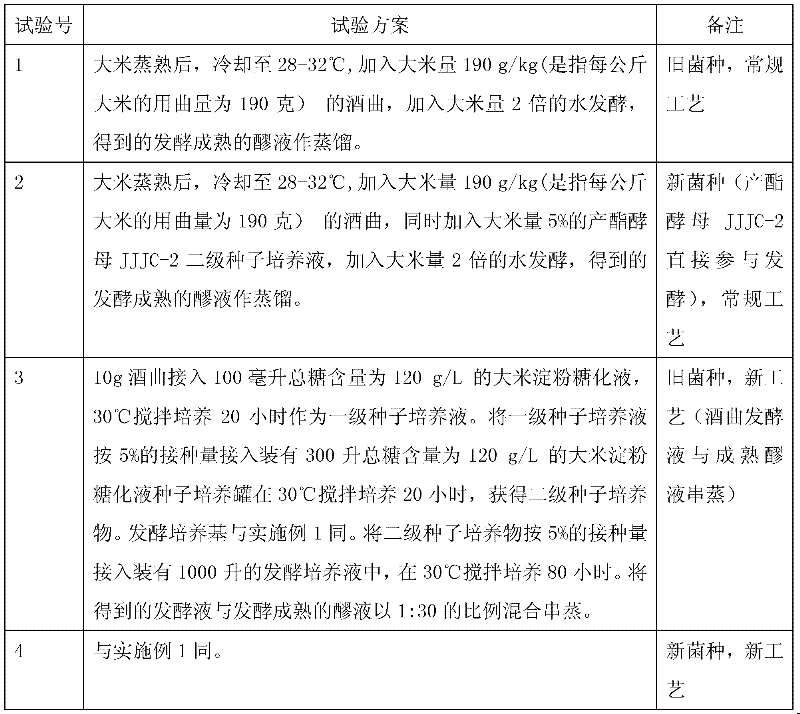

Embodiment 1

[0029] Utilize ester-producing yeast JJJC-2 to ferment and produce ethyl acetate and alcohol, the steps are as follows:

[0030] 1) Incline strain: inoculate the ester-producing yeast JJJC-2 strain on the wort solid slope with a total sugar content of 60g / L, culture it at 28°C for 48 hours, and store it in a refrigerator at 4°C;

[0031] 2) Liquid strain: After activating the preserved ester-producing yeast JJJC-2 slant strain, a ring of cells was placed in an Erlenmeyer flask containing 100 milliliters of wort liquid medium with a total sugar content of 120 g / L. Stirring and culturing at 30°C for 20 hours, it is a liquid strain;

[0032] 3) First-level liquid seed cultivation: put the liquid bacteria into a triangular flask containing 200 ml of rice starch saccharification solution with a total sugar content of 120 g / L according to the inoculum amount of 5%, and culture it under stirring at 30°C for 18 hours , to obtain a first-level liquid seed culture;

[0033] 4) Seconda...

Embodiment 2

[0042] Utilize ester-producing yeast JJJC-2 to ferment and produce ethyl acetate and alcohol, the steps are as follows:

[0043] 1) The slant JJJC-2 was cultured at 30°C for 36 hours, and stored in a 4°C refrigerator;

[0044] 2) Liquid strain: After activating the preserved ester-producing yeast JJJC-2 slant strain, a ring of cells was placed in an Erlenmeyer flask containing 100 ml of wort liquid medium with a total sugar content of 160 g / L. Stirring and culturing at 30°C for 20 hours, it is a liquid strain;

[0045] 3) First-level liquid seed culture: put the liquid bacteria into a triangular flask containing 200 ml of rice starch saccharification solution with a total sugar content of 160 g / L according to the inoculum amount of 10%, and culture it under stirring at 30°C for 20 hours , to obtain a first-level liquid seed culture;

[0046] 4) Secondary liquid seed culture: the primary seed culture solution was inserted into a 300 liter rice starch saccharification liquid see...

Embodiment 3

[0056] Utilize ester-producing yeast JJJC-2 to ferment and produce ethyl acetate and alcohol, the steps are as follows:

[0057] 1) Incline strain: inoculate the ester-producing yeast JJJC-2 strain on the wort solid slope with a total sugar content of 20g / L, culture it at 25°C for 30 hours, and store it in a 4°C refrigerator;

[0058] 2) Liquid strain: After activating the preserved ester-producing yeast JJJC-2 slant strain, a ring of cells was placed in an Erlenmeyer flask containing 100 milliliters of wort liquid medium with a total sugar content of 80 g / L. Stir and cultivate at 25°C for 16 hours to obtain liquid strains;

[0059] 3) Level 1 liquid seed culture: put the liquid bacteria into a triangular flask containing 200 ml of barley starch saccharification solution with a total sugar content of 80 g / L according to an 8% inoculum size, and culture it under stirring at 25°C for 16 hours , to obtain a first-level liquid seed culture;

[0060] 4) Secondary liquid seed cult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com