Oxiracetam compound with steady crystal form

A compound and diffraction angle technology, applied in the field of medicine, can solve the problems of preference for substance content, lack of fine filtration, low yield, etc., and achieve the effects of low content of related substances, reduction of side reactions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

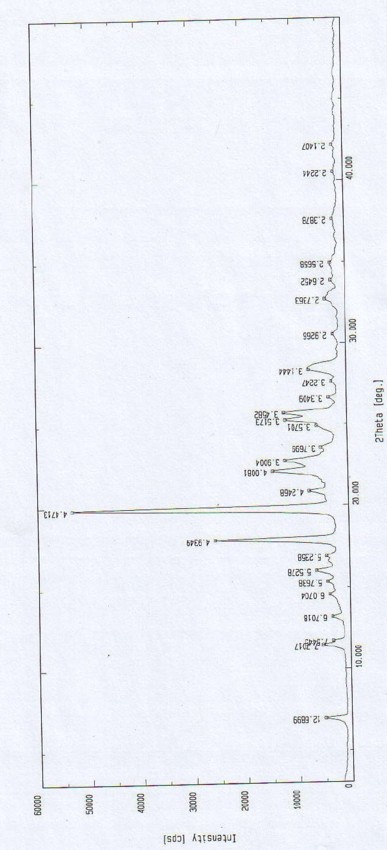

Image

Examples

Embodiment 1

[0057] Add the crude oxiracetam to 99% methanol, heat to 75°C to dissolve it, add activated carbon for 30 minutes, filter while it is hot, continue to pass the filtrate through a 0.45um microporous membrane, collect the filtrate, and then Continue to heat up the filtrate to 75°C, slowly cool down to about 40°C, control the temperature at 38-42°C for 2.5 hours, keep the crystal for 2.5 hours, then continue to cool down to 4-10°C for 2.5 hours, then slowly cool down, cool and crystallize, and finally collect the crystals , Yield: 92.1%, content 100.2%.

Embodiment 2

[0059] Add the crude oxiracetam to 80% methanol, heat to 80°C to dissolve it, add activated carbon for 30 minutes, filter while it is hot, continue to pass the filtrate through a 0.45um microporous membrane, collect the filtrate, and then Continue to heat up the filtrate to 80°C, slowly cool down to about 40°C, control the temperature at 38-42°C for 3 hours, keep the crystal for 3 hours, then continue to cool down to 4-10°C for 3 hours, then slowly cool down, cool and crystallize, and finally collect the crystals , Yield: 91.8%, content 100.1%.

Embodiment 3

[0061] Add the crude oxiracetam to 95% methanol, heat it to 65°C to dissolve it, add activated carbon for 30 minutes, filter while it is hot, continue to pass the filtrate through a 0.45um microporous membrane, collect the filtrate, and then Continue to heat up the filtrate to 65°C, slowly cool down to about 40°C, control the temperature at 38-42°C for 2 hours, keep the crystal for 2 hours, then continue to cool down to 4-10°C for 3 hours, then slowly cool down, cool and crystallize, and finally collect the crystals , Yield: 91.1%, content 100.0%.

[0062] The oxiracetam compound obtained by the present invention has high purity, high yield, and low impurity content, which effectively improves the therapeutic effect of the product and reduces side reactions; meanwhile, the yield is improved, the cost is reduced, and higher benefits are created .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com