Magnetic absorption type wall climbing robot

A wall-climbing robot and magnetic adsorption technology, applied in the field of robots, can solve the problems affecting the adsorption force of the wall-climbing robot, slipping or overturning of the wall-climbing robot, etc., and achieve the effect of enhancing dynamic performance and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

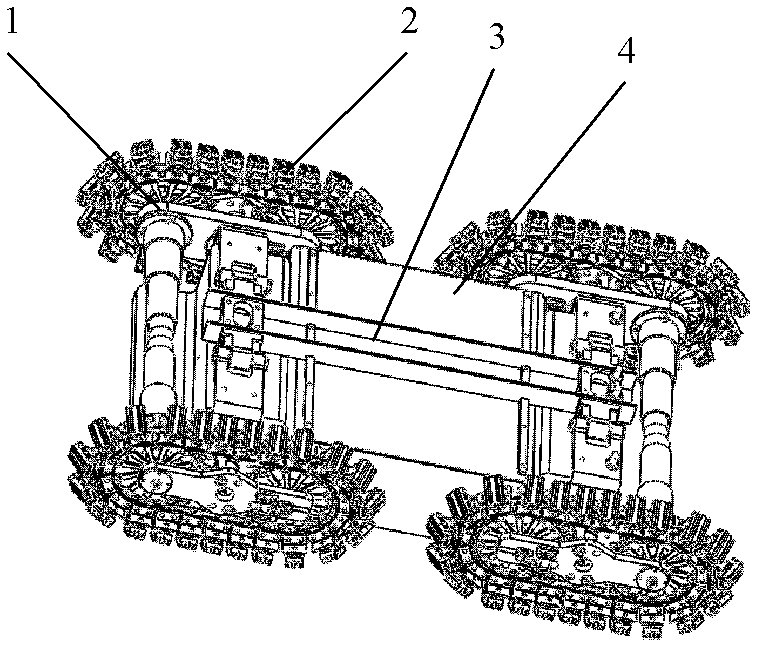

[0025] combined with figure 2 The magnetic adsorption wall-climbing robot includes four drive units 1, four chain crawlers 2, a control system and a robot box 4. The robot box shell consists of a front side panel, an upper cover, a rear side panel, a lower panel and The side panels of the shell are connected into a closed structure; the overall connection relationship is: two drive units 1 are installed on the left and right sides of the robot box shell, and each drive unit 1 is connected in the same way and equipped with a motor and a reducer 9, each The inside of the chain crawler 2 is equipped with a load dispersion mechanism; the control system is placed on the circuit mounting plate in the robot box 4 and connected with four drive units 1;

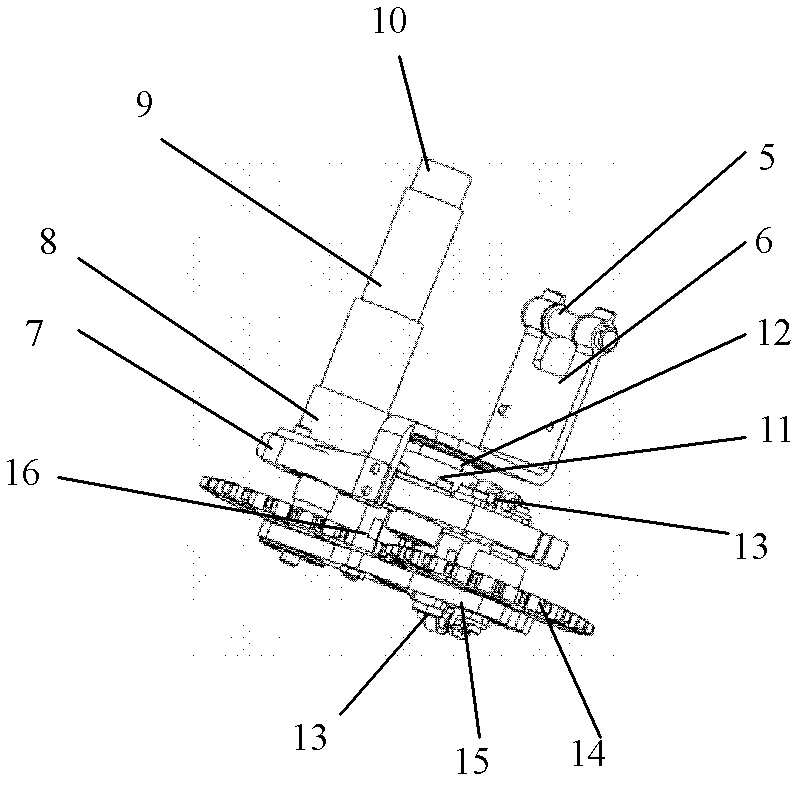

[0026] combined with image 3 The drive unit includes a code disc 10, a servo motor and a reducer 9, a motor fixed shaft 8, a middle inner plate of the track 7, a track sprocket 14, a middle outer plate of the track 7, a tightness a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com