Automobile chassis cleaning and baking device

A technology for drying devices and automobile chassis, which is applied in the direction of vehicle exterior cleaning devices, cleaning methods and tools, cleaning methods using liquids, etc., and can solve problems such as small cleaning area, uneven pressure, and inability to clean automobile chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

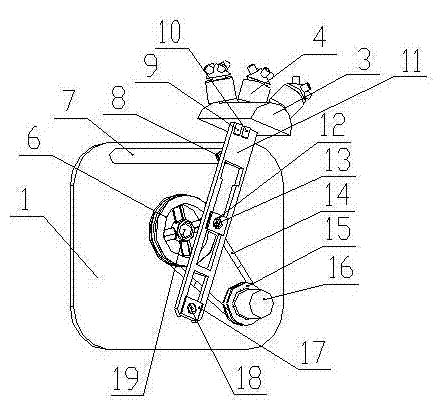

[0015] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

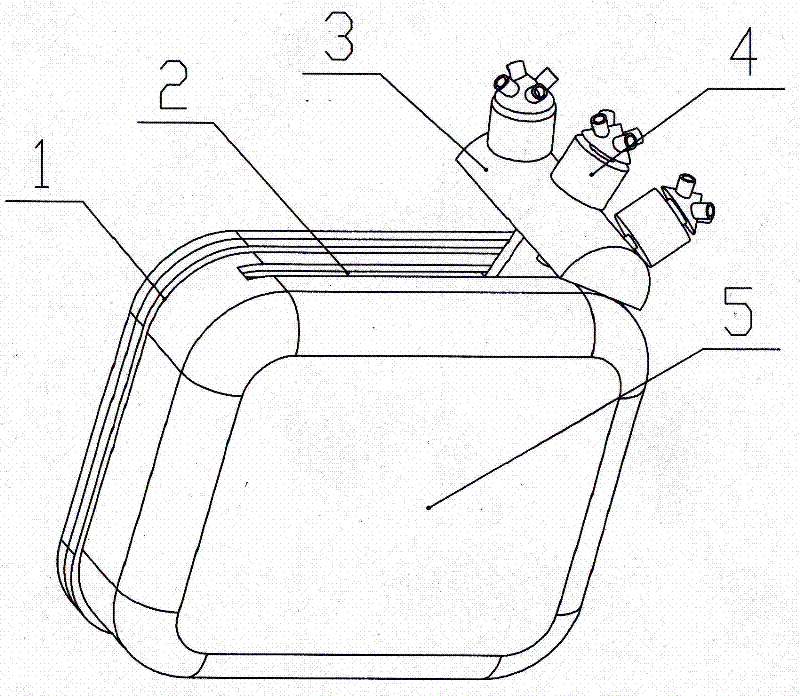

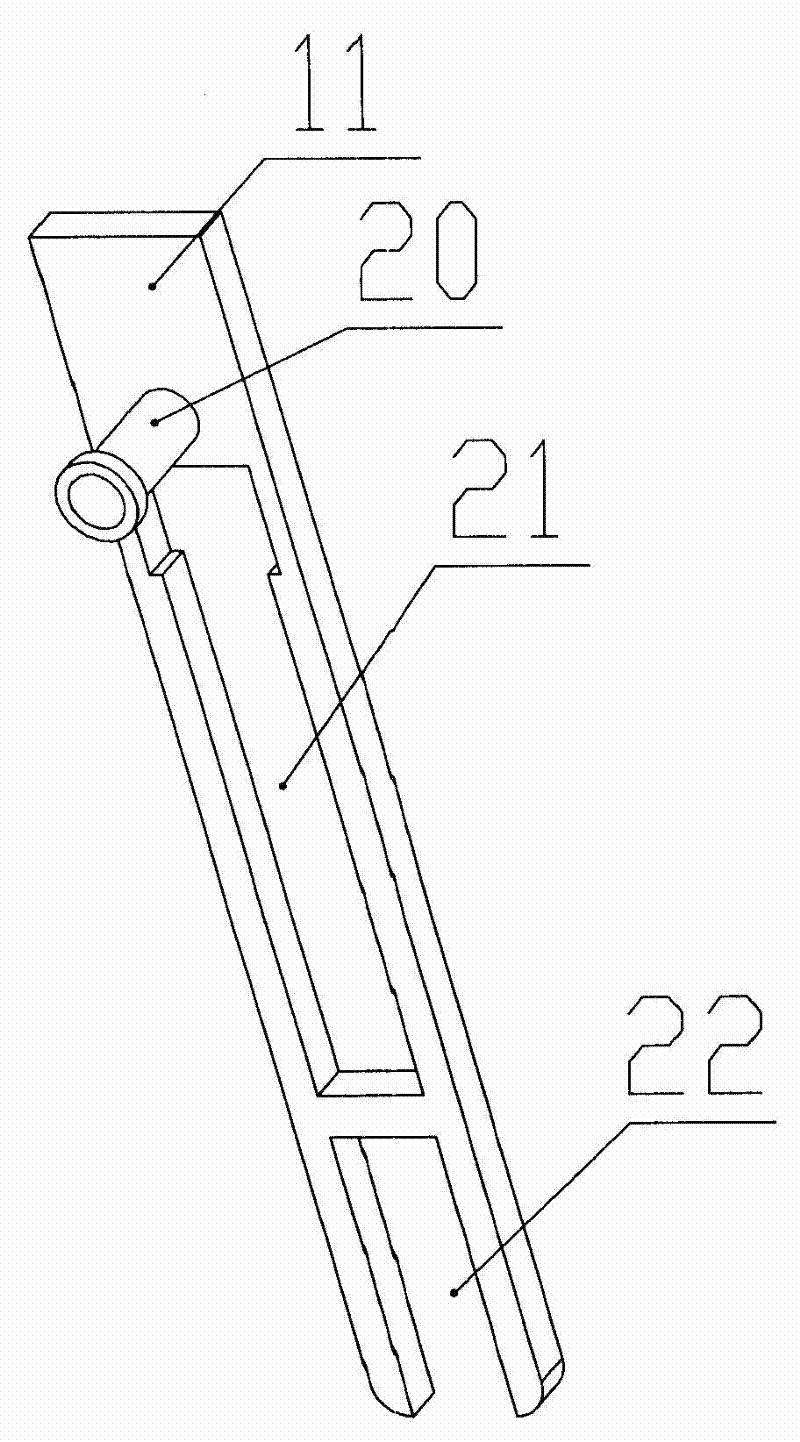

[0016] Such as figure 1 , 2 , 3, the automobile chassis cleaning and drying device mainly includes a frame 1, a motor 16, a rocker arm 11 and a rotary spray nozzle 4; 19 and shaft B 18, driving wheel 15 is installed on the motor 16 shaft, driven wheel 6 is installed on the shaft A 19, conveyor belt 14 is set on the driving wheel 15, driven wheel 6, an eccentric shaft 13 is installed on the driven wheel 6, eccentric The shaft 13 and the shaft B 18 are respectively equipped with a first slide block 12 and a second slide block 17; the rocking arm 11 is provided with a first slide groove 21 and a second slide groove 22; Block 17 is respectively positioned in the first chute 21, the second chute 22; Described rocking arm 11 top is equipped with pulley shaft 20, and pulley 8 is installed on the pulley shaft, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com