Anti-fogging meter

An instrument and anti-fog technology, applied in the field of instruments, can solve problems such as short effective time, damage to water surface tension, and poor anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

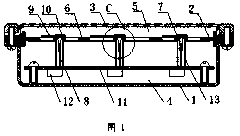

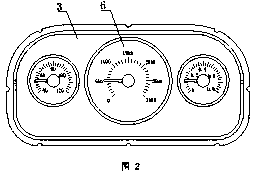

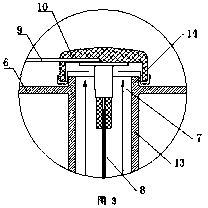

[0026] like Figure 1 to Figure 3 As shown, the anti-fog instrument includes an instrument panel lower case 1, an instrument panel upper case 2 is sealed and installed on the instrument panel lower case 1, and the instrument panel lower case 1 and the instrument panel upper case 2 is provided with a sealant layer, an instrument panel rear chamber 4 is formed between the instrument panel lower case 1 and the instrument panel upper case 2; a transparent gauge is sealed and installed on the instrument panel upper case 2 Front cover 3, a sealant layer is provided at the connection between the instrument panel upper case 2 and the instrument panel front cover 3, and an instrument panel front chamber is formed between the instrument panel upper case 2 and the instrument panel front cover 3 5. The front cavity 5 of the instrument panel is smaller than the rear cavity 4 of the instrument panel; a dial 6 is installed on the lower surface of the upper housing 2 of the instrument panel; ...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, except that the meter shaft sealing isolation device includes a meter shaft spacer sleeve fixedly arranged on the upper surface of the instrument core mounting plate 11 and distributed around the meter shaft 8 13. The meter shaft spacer 13 is integrally formed on the upper surface of the meter core mounting plate 11; a sealant layer is provided between the upper end of the meter shaft spacer 13 and the lower surface of the dial 6, The number of the table shaft spacer 13 is consistent with the number of the table shaft 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com