Mark printing method

A technology of marking and marking layer, applied in printing, printing device, printing process and other directions, can solve the problems of difficult identification, logo deformation, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

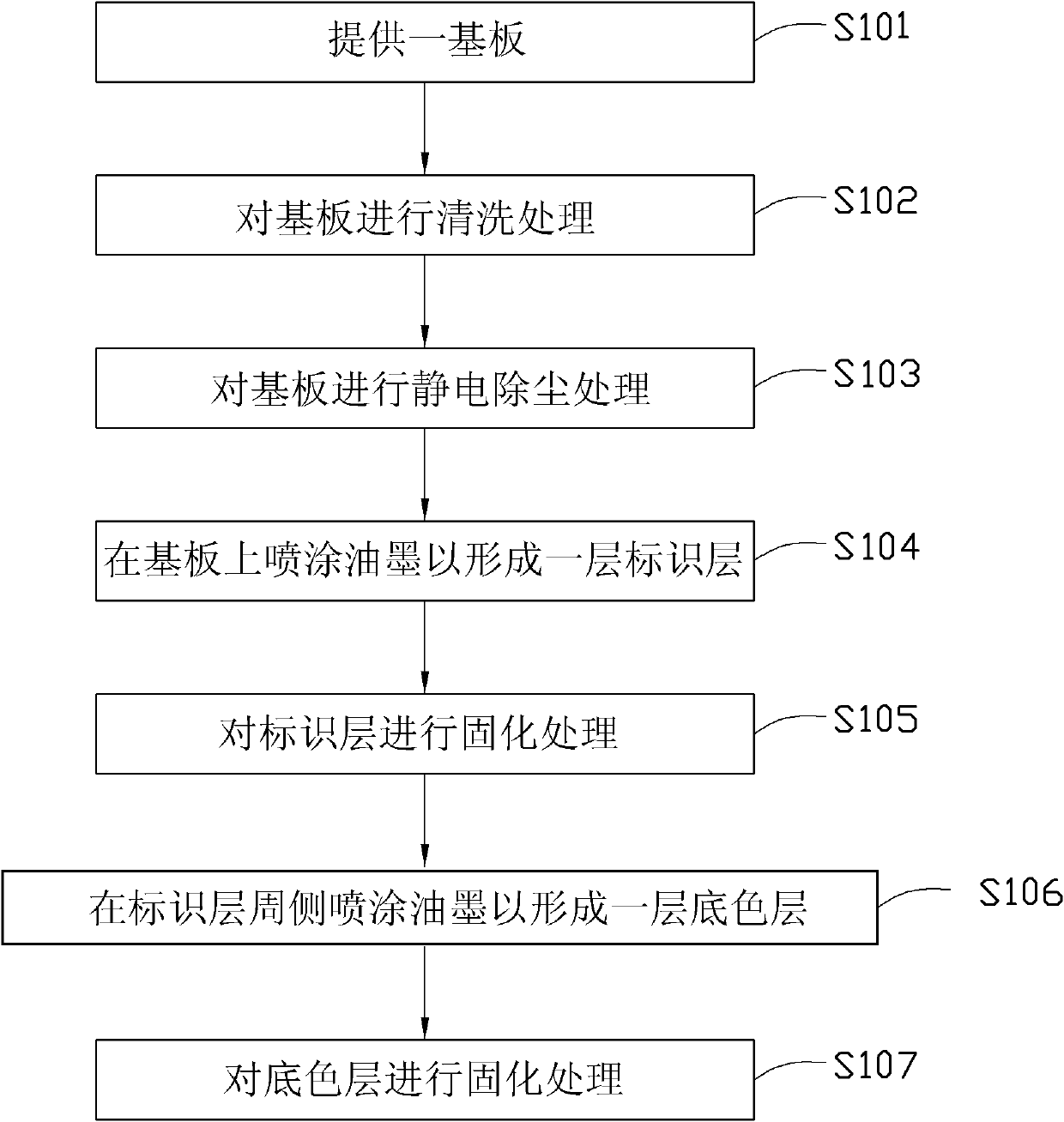

[0012] Combine below Figure 1 to Figure 4 The logo printing method according to the embodiment of the present invention will be described in detail.

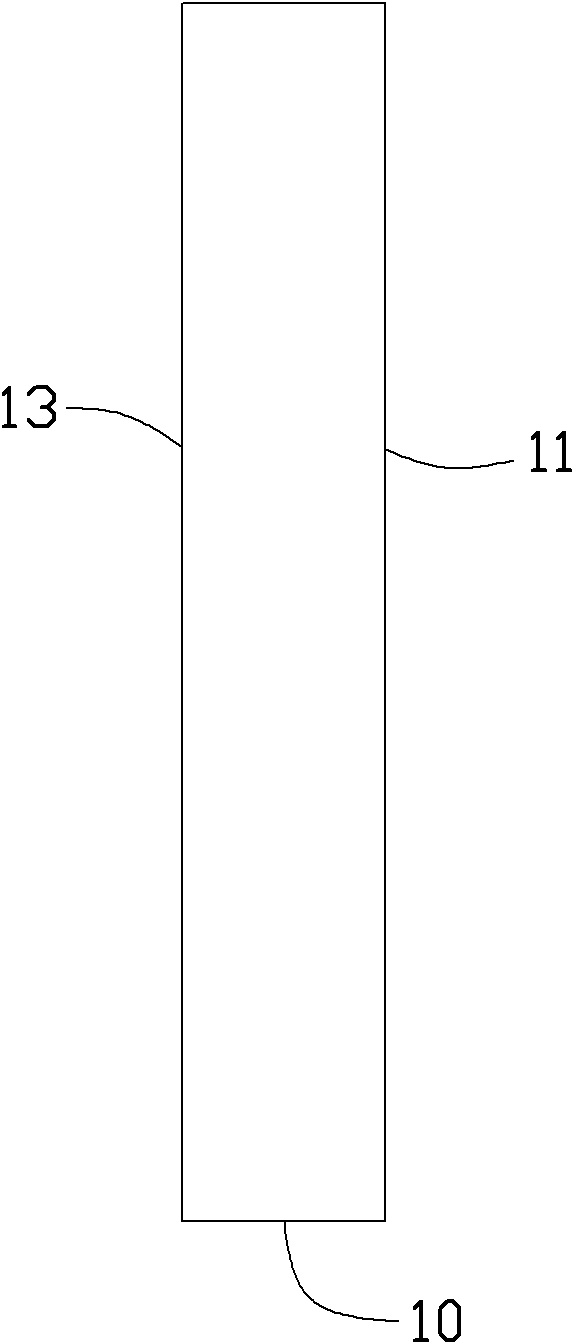

[0013] In step S101, a substrate 10 is provided, and the substrate 10 is made of a light-transmitting material. In this embodiment, the substrate 10 is a mobile phone key cap, which includes a pressing surface 11 and a printing surface 13 opposite to the pressing surface 11 . In order to make the substrate 10 have a smaller roughness, the pressing surface 11 and the printing surface 13 can be polished or polished.

[0014] In step S102, the substrate 10 is cleaned. In this embodiment, alcohol is used to wipe or wash the printing surface 13 of the substrate 10 to remove oil stains, dust, lint, etc. on the surface.

[0015] In step S103 , electrostatic dust removal treatment is performed on the substrate 10 . In an embodiment, an electrostatic dedusting gun (not shown) is used to perform electrostatic dedusting treatment on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com