An oblique wedge telescopic stainless steel mobile climbing ladder

A telescopic, stainless steel technology, applied in the field of climbing ladders, can solve the problem that the climbing ladders cannot pass through the conveying line normally, and achieve the effect of simple fixed operation, light movement, and clean protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

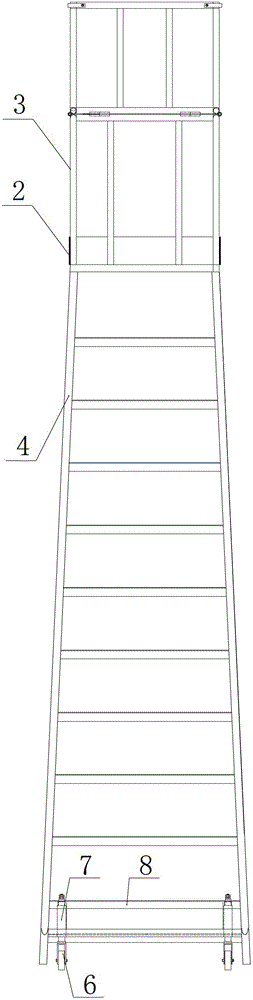

[0018] Such as figure 1 , figure 2 Shown is a kind of oblique wedge telescopic stainless steel mobile climbing ladder, which includes a ladder frame 1, a platform 2, a pedal 4, a guardrail 3, handrails 5, four casters 6 and four caster mounting frames 7, the ladder frame 1 The rear bottom is provided with rollers 11. The platform 2 is arranged on the top of the ladder frame 1, and the guardrail 3 is arranged around the platform 2, and the guardrail 3 adopts a foldable guardrail 3. The pedal 4 is arranged on the front side of the ladder frame 1 along the slope of the ladder frame 1 , and the handrails 5 are arranged on both sides of the pedal 4 . Among the four casters 6, the casters 6 at the two corners of the front are fixed casters, and the casters 6 at the two corners of the rear are universal movable casters.

[0019] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com