Water jet cutting actuating device

An actuator and water jet technology, applied in metal processing, etc., can solve problems such as inconvenient disassembly, difficult cutting, difficult transportation, etc., and achieve the effects of easy storage, space saving, and levelness assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

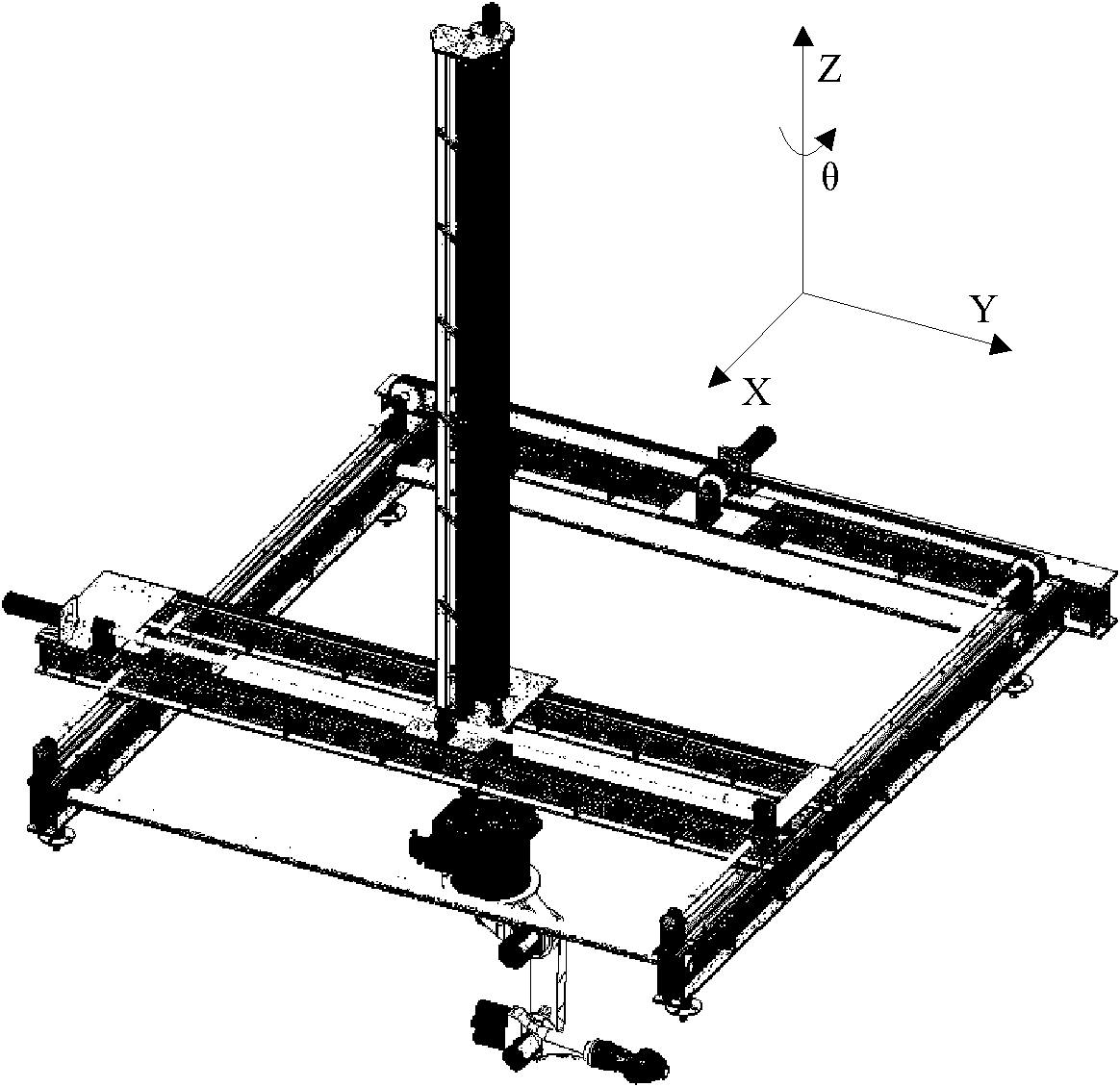

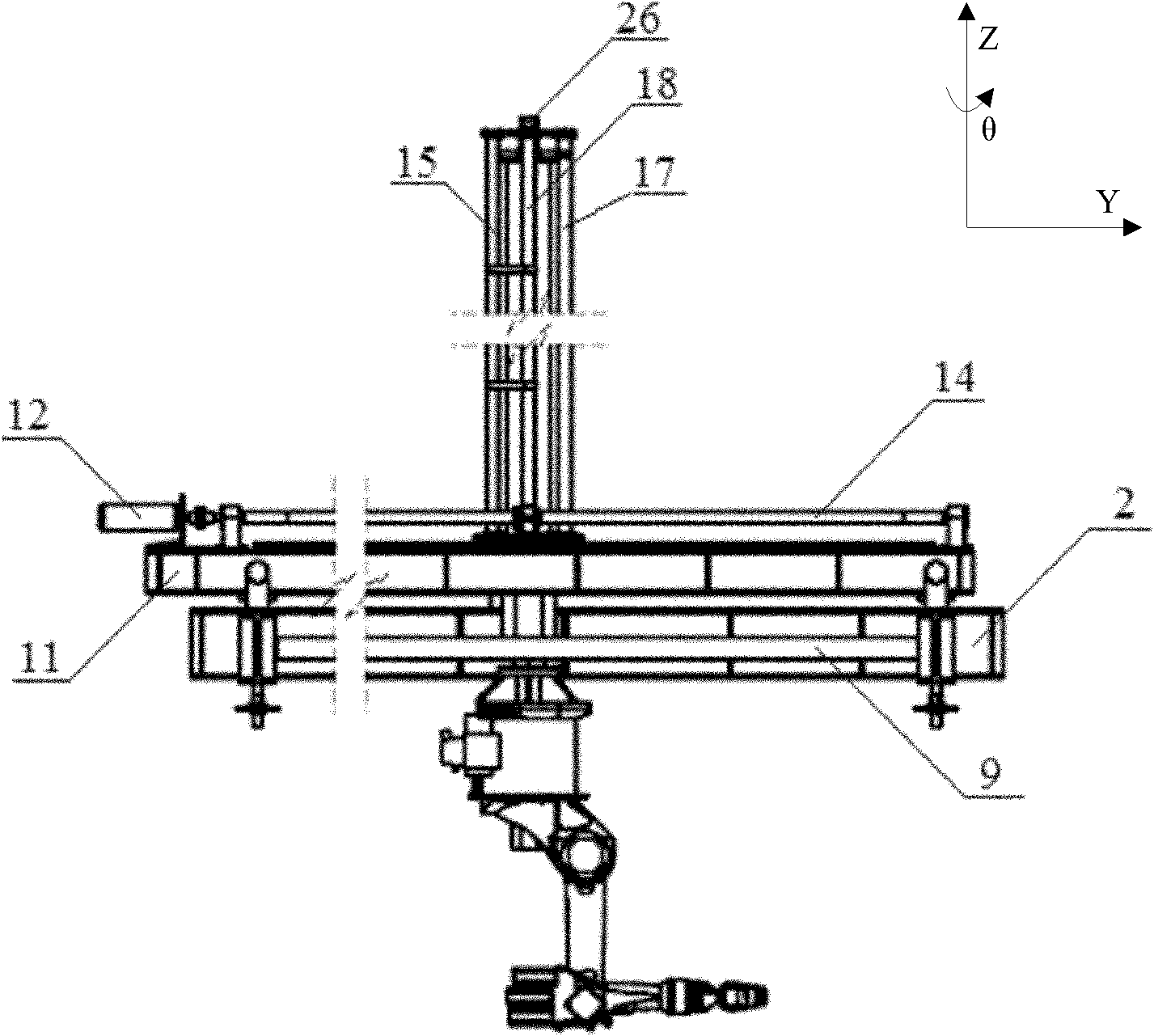

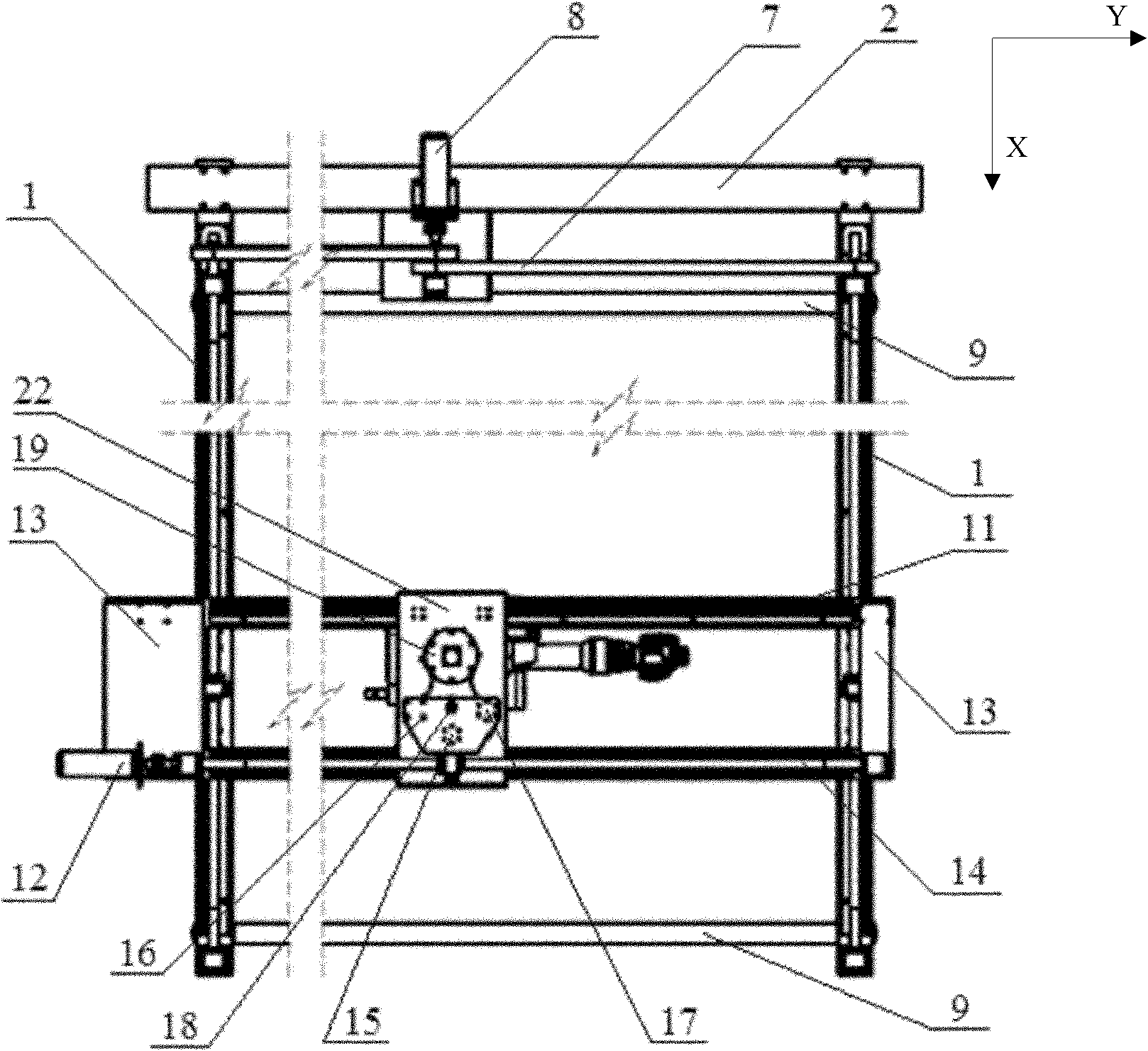

[0045] like Figure 1~3 As shown, a water jet cutting execution device of the present invention includes an X-direction movement module, a Y-direction movement module, a Z-direction movement module, a θ-direction movement module and a water jet cutting machine. The X-direction movement module is mainly composed of the X-direction support beam 1 and the first motor beam 2, the Y-direction movement module is mainly composed of the Y-direction motor beam 11 and the second motor beam, and the Z-direction movement module is mainly composed of the Z-direction support rod 15 and the guide rail. The support rod 16, the guide rod 17, the Z-direction ball screw 18, and the outer cylinder 19 are composed, and the θ-direction movement module is mainly composed of the inner cylinder 25 and the θ-direction motor 26. Its overall positional relationship is: with the X-direction movement module as the base, the Y-direction movement module is supported on the X-direction movement module, which ...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063]The X-direction movement module also includes two horizontal adjustment rods 9 and four vertical adjustment nuts 10 . Among them, two horizontal adjustment rods 9 are installed between the two X-direction support beams 1 in a direction perpendicular to the X-direction support beam 1, and the two horizontal adjustment rods 9 are respectively located at the first and last ends of the X-direction support beam 1; The vertical adjustment nuts 10 are respectively installed on the lower ends of the two X-direction support beams 1 . In addition, height-adjustable rack legs can also be respectively installed under the vertical adjustment nuts 10 .

[0064] The horizontal adjustment rod 9 can not only adjust the distance between the two ends of the two X-direction support beams 1 according to the actual situation, thereby adjusting their parallelism, but also can play the role of strengthening the X-direction mo...

Embodiment 3

[0066] The difference between this embodiment and the above two embodiments is:

[0067] The inner wall of the guide cylinder 20 in the Z-direction movement module is interference-fitted with a liner. The material of the liner is preferably polytetrafluoroethylene, and the inner wall may have several rectangular grooves.

[0068] This design can not only reduce the friction between the outer cylinder 19 and the guide cylinder 20, but also guide the attached water of the outer cylinder 19 back to the pool through the rectangular groove when the outer cylinder 19 is lifted to the guide cylinder 20 after the water cutting is completed. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com