Special numerical-control grinding and milling machine for cams with arc-shaped surfaces

A cambered cam, grinding and milling technology, applied in the field of numerical control machine tools, can solve the problems of difficult machining, complex shape, difficult processing and manufacturing, etc., and achieve the effect of continuous grinding and milling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The idea, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0019] It should be emphasized that the positional relationships such as up, down, front, back, left and right mentioned in the present invention are all based on the drawings of the present invention, and should not be construed as limiting the present invention.

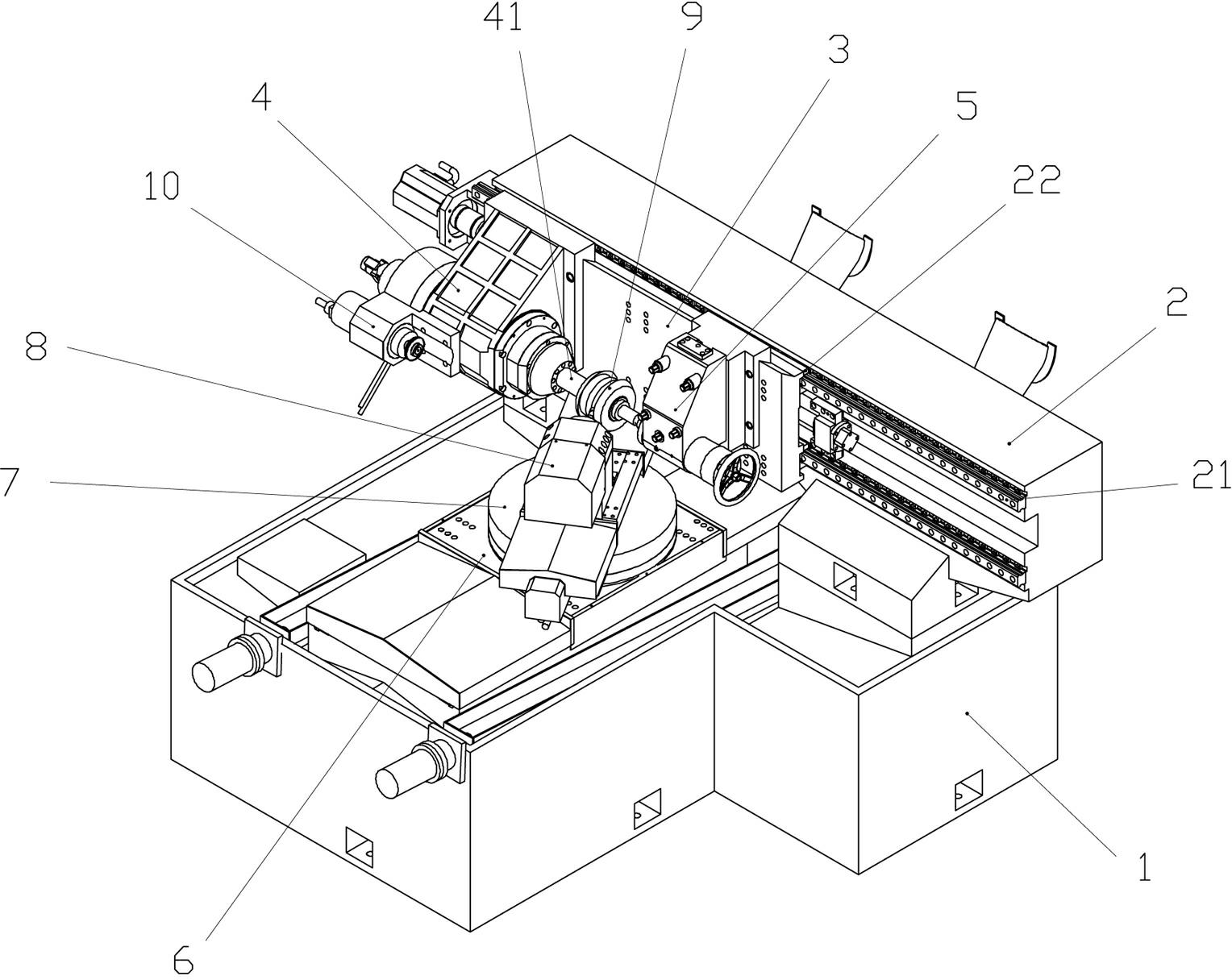

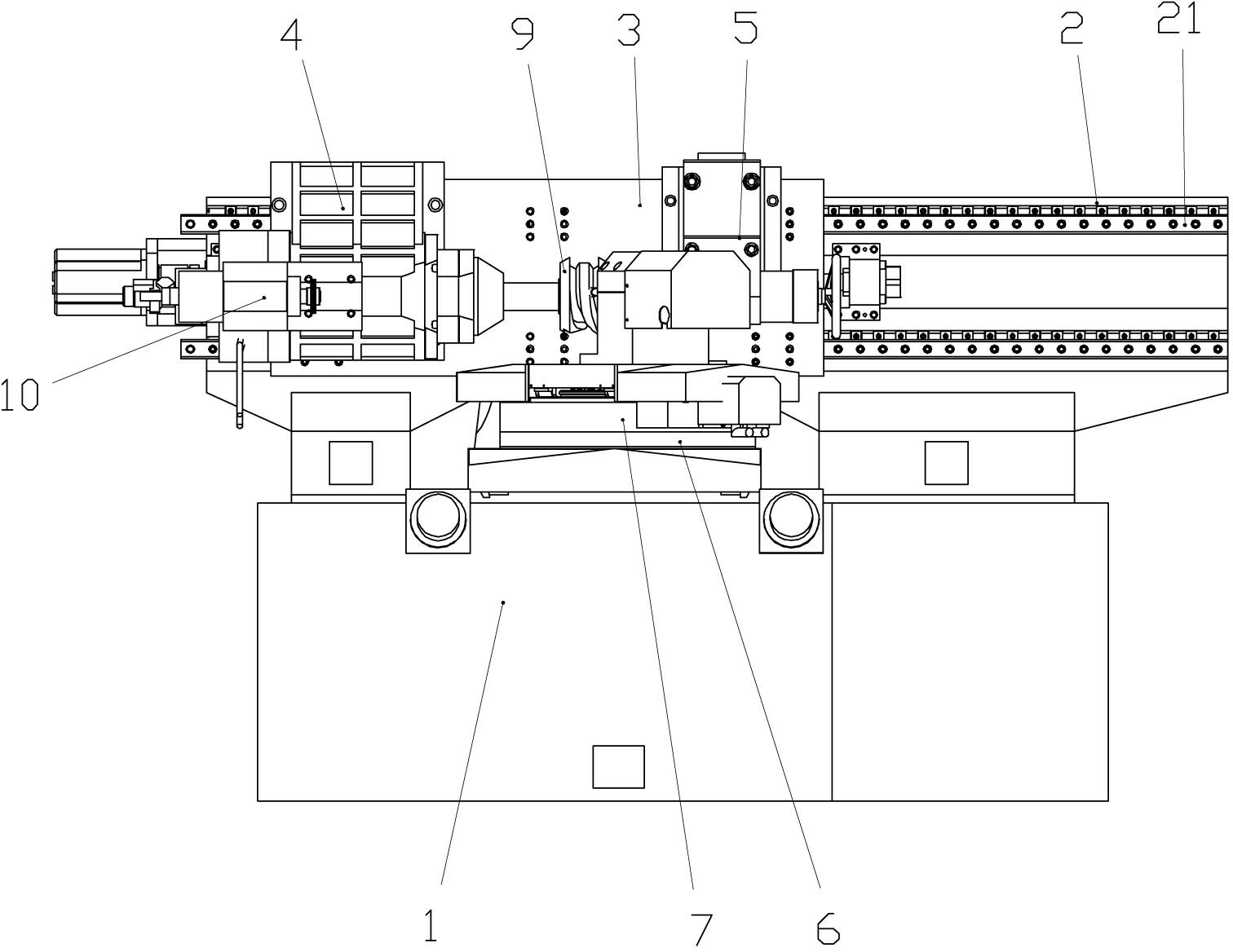

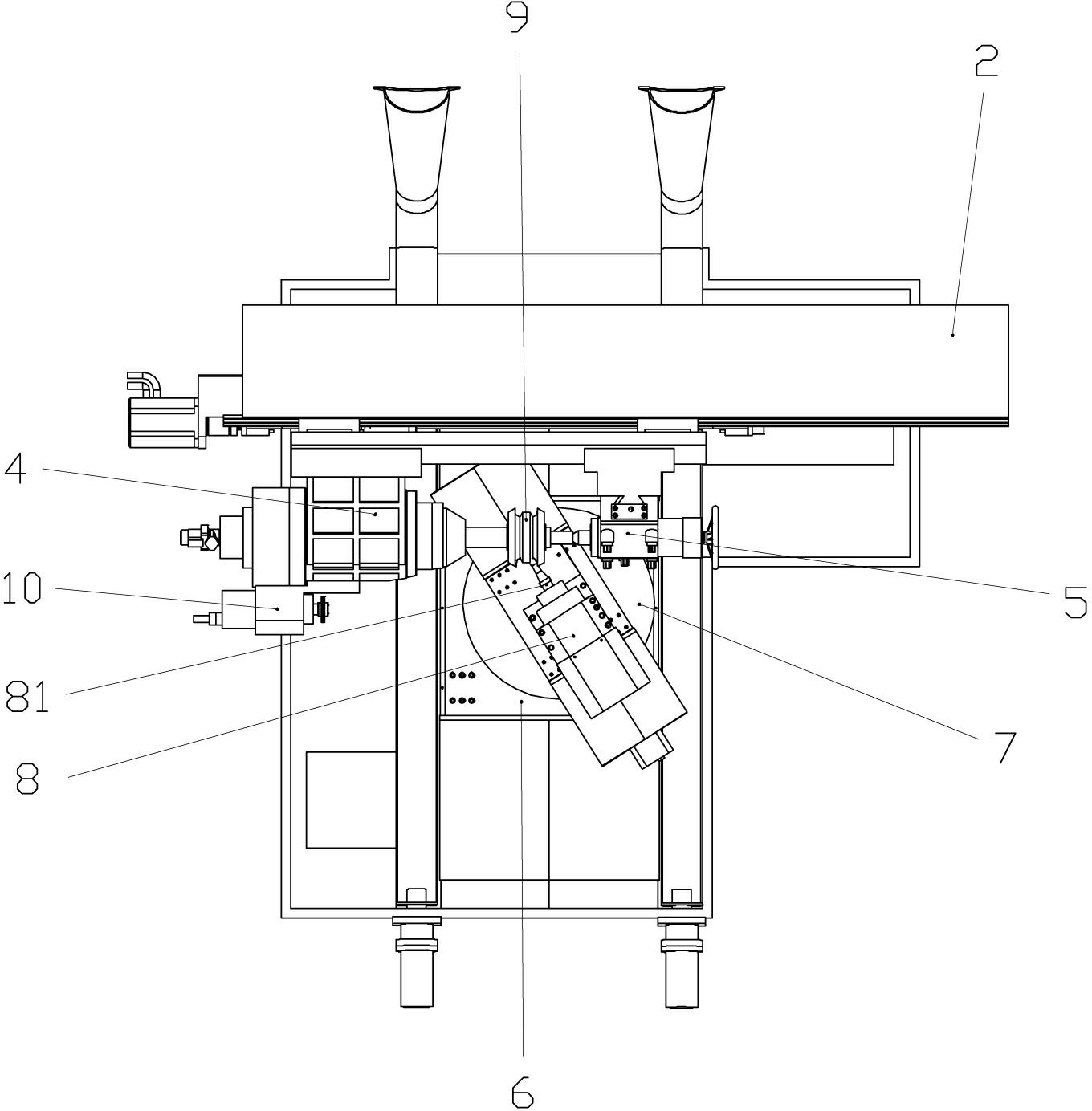

[0020] refer to figure 1 , figure 2 and image 3 , a structural schematic diagram of various angles of an embodiment of the arc cam CNC milling machine of the present invention, which includes a bed 1, a beam 2 is arranged on the bed 1 along the X direction, and a front end of the beam 2 is provided with X-direction skateboard 3. In this embodiment, the X-direction slide plate 3 is slidably coupled to the crossbeam 2 through the X-dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com