A double-sided precision machining method for large flat thin-walled parts

A technology for precision machining and thin-walled parts, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as difficult to ensure processing accuracy and processing efficiency, workpiece deformation, difficult operation, etc., and shorten the time of degumming The effect of reducing time, reducing workpiece deformation, and ensuring processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

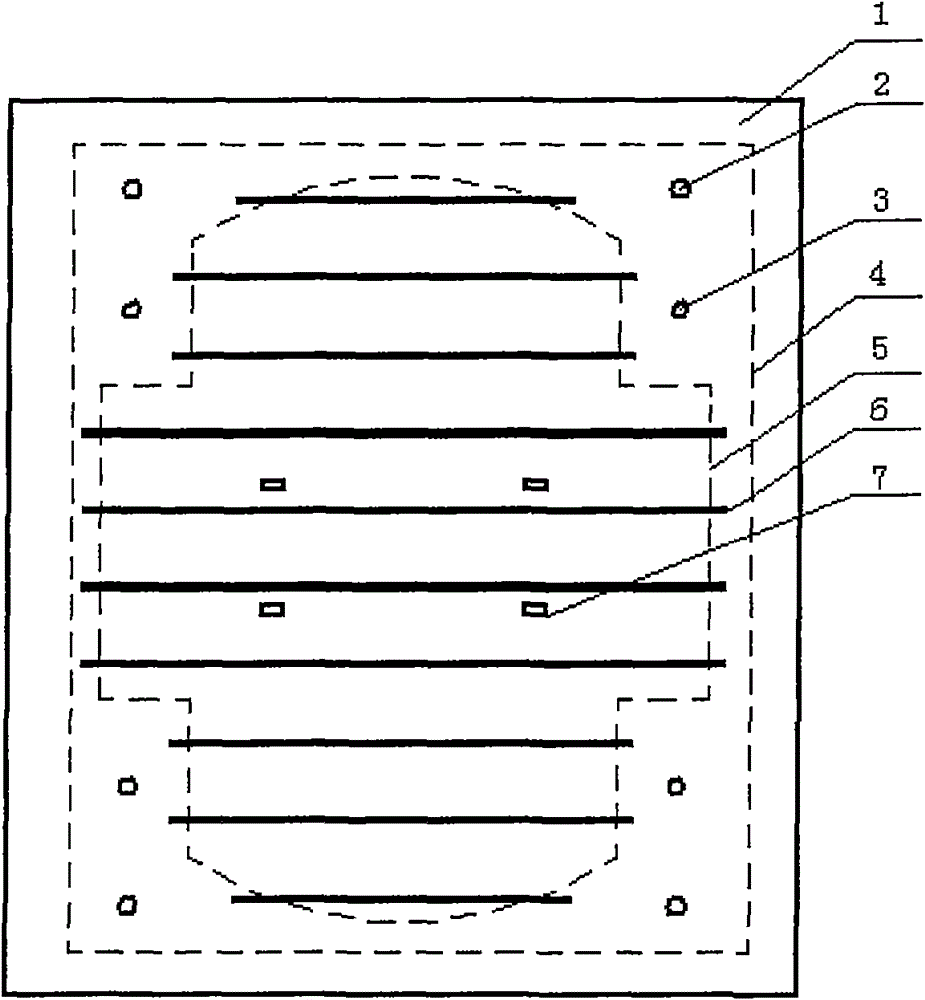

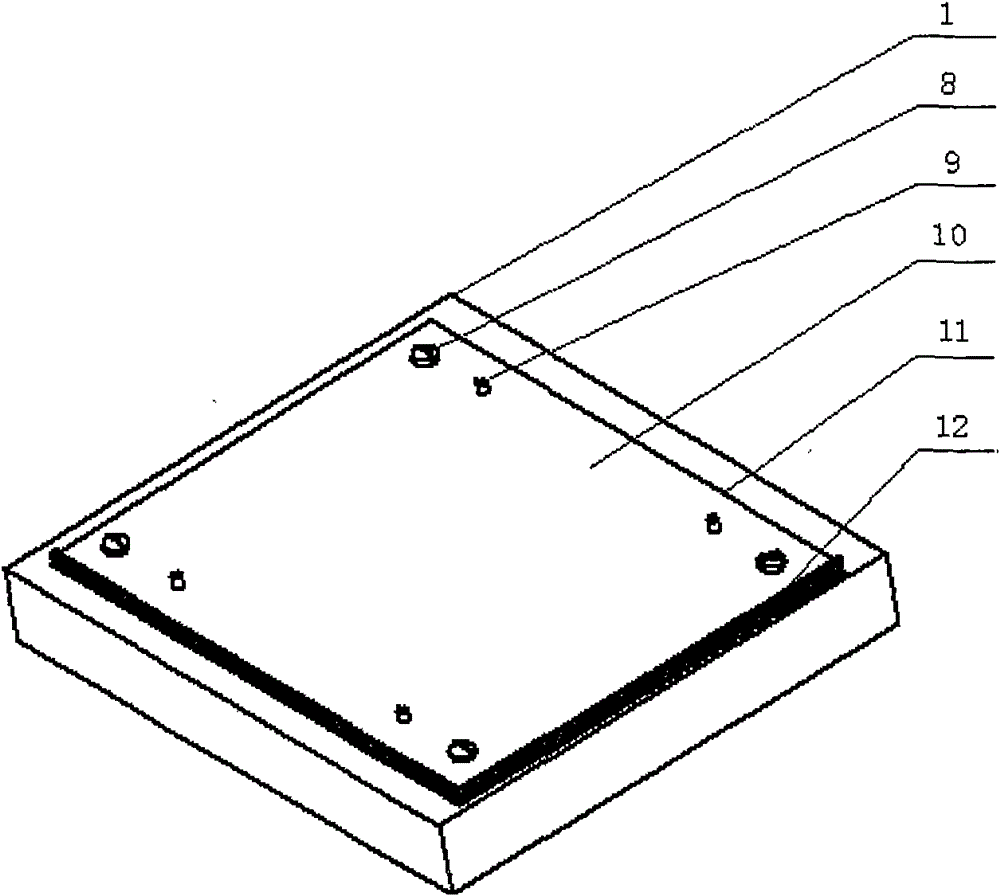

[0030] according to figure 1 as shown, figure 1 Middle: 1 is the 3R tooling plate; 2 is the compression screw hole; 3 is the pin hole; 4 is the workpiece blank shape; 5 is the actual shape of the workpiece; 6 is the permeation groove; 7 is the relief groove of the boss.

[0031] The implementation manner of a specific example is given below.

[0032] (1) First side processing

[0033] In order to facilitate the subsequent gluing, the surface with less features such as surface bosses and other easy-to-process surfaces can be selected as the first surface of the workpiece to be processed. It is carried out by ordinary CNC machining methods, and clamped on the CNC machine tool by screw compression. Carry out pre-drilling and reaming positioning pin holes on the surface of the workpiece while processing the first surface to meet the positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com