Multifunctional composite electromachining spindle

An electric machining and multi-functional technology, applied in the direction of electric machining equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of large electrode loss, poor versatility of ultrasonic machining parts, and low efficiency of electric machining spindles, etc., to achieve reasonable structure and general use The effect of strong and precise indexing and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

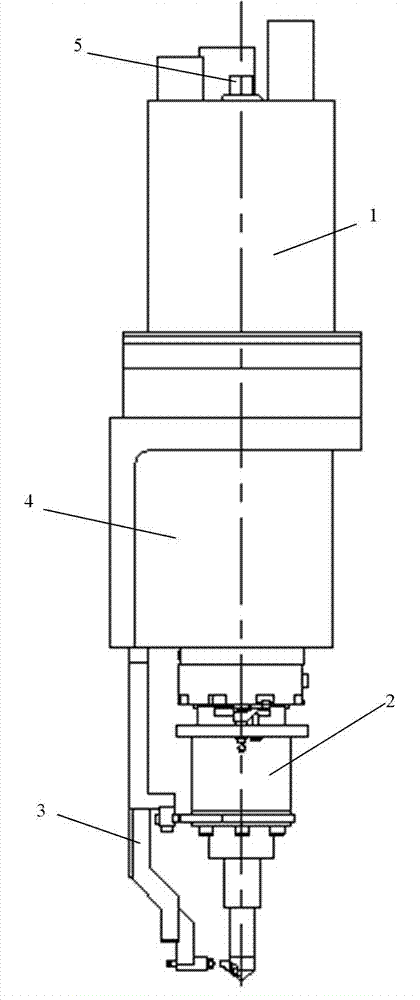

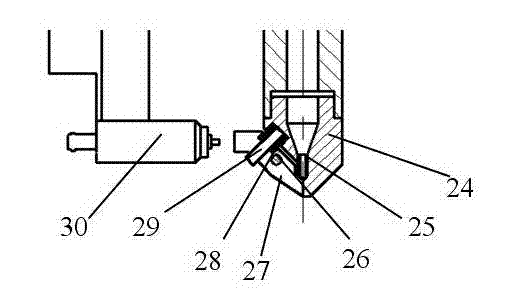

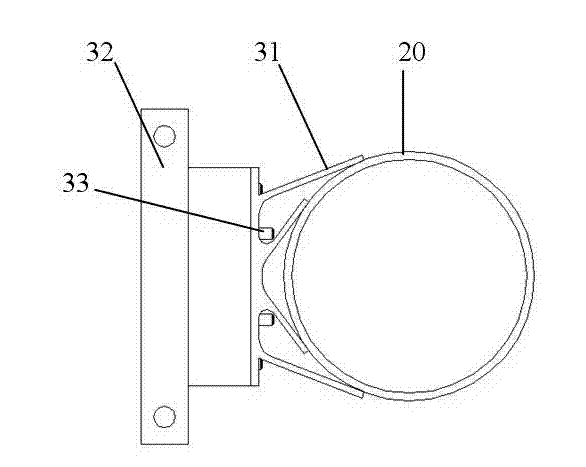

[0018] figure 1 It is a schematic diagram of the overall structure of the multifunctional and multifunctional composite electrical machining spindle of the present invention, figure 2 It is a partial cross-sectional schematic diagram of the multifunctional composite electrical machining spindle of the present invention, image 3 It is a schematic view of the structure of the collet in the present invention, Figure 4 It is a structural schematic diagram of the power supply mechanism in the present invention, in figure 1 — Figure 4 Among them, the multifunctional composite electrical machining spindle of the present invention includes a rotary mechanism 1, a spindle electrode chuck 2, a power supply mechanism 3, a spindle support 4 and an automatic wire feeding mechanism 5; the multifunctional composite electrical machining spindle is cylindrical and is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com