Automatic ignition and air entraining device and method for full automatic casting machine

An automatic ignition and pouring machine technology, which is applied in the direction of metal processing equipment, casting equipment, manufacturing tools, etc., can solve the problems of poor cavity exhaust, personal injury, high labor intensity, etc., to avoid personal safety accidents, ignition and air bleed Timely and accurate, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

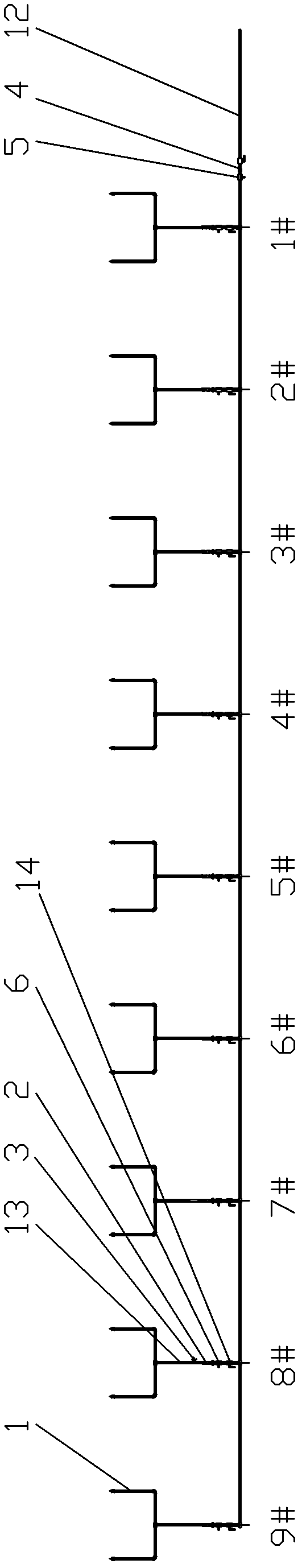

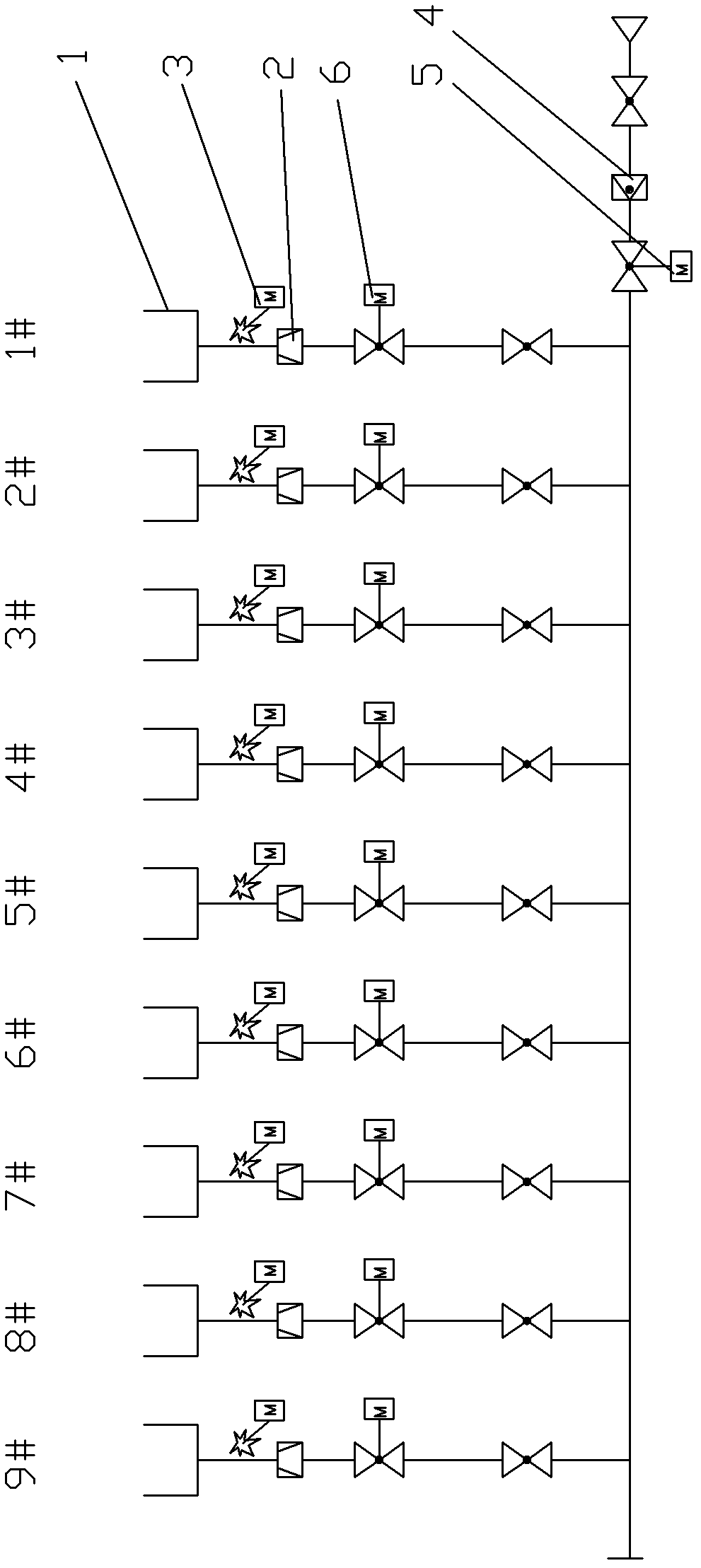

[0026] refer to figure 1 and figure 2 , the automatic ignition air-inducing device of the automatic pouring machine of the present invention includes a natural gas main intake pipe 12 and a group of parallel natural gas sub-intake pipes 13, and the sub-intake pipes 13 correspond to the number of stations. In this embodiment , the number of stations is 9. Said total air intake pipe 12 is provided with a pressure regulating valve 14 and a total electromagnetic valve 5 on the front end pipeline of said sub-intake pipe 13; said each sub-intake pipe 13 is provided with a sub-electromagnetic valve 6 and an ignition mechanism in turn. 7. The ignition mechanism 7 includes a burner 2 and an electronic igniter 3, the end of which is connected to a fire pipe 1; the main solenoid valve 5 and each sub solenoid valve 6 are connected to a PLC controller.

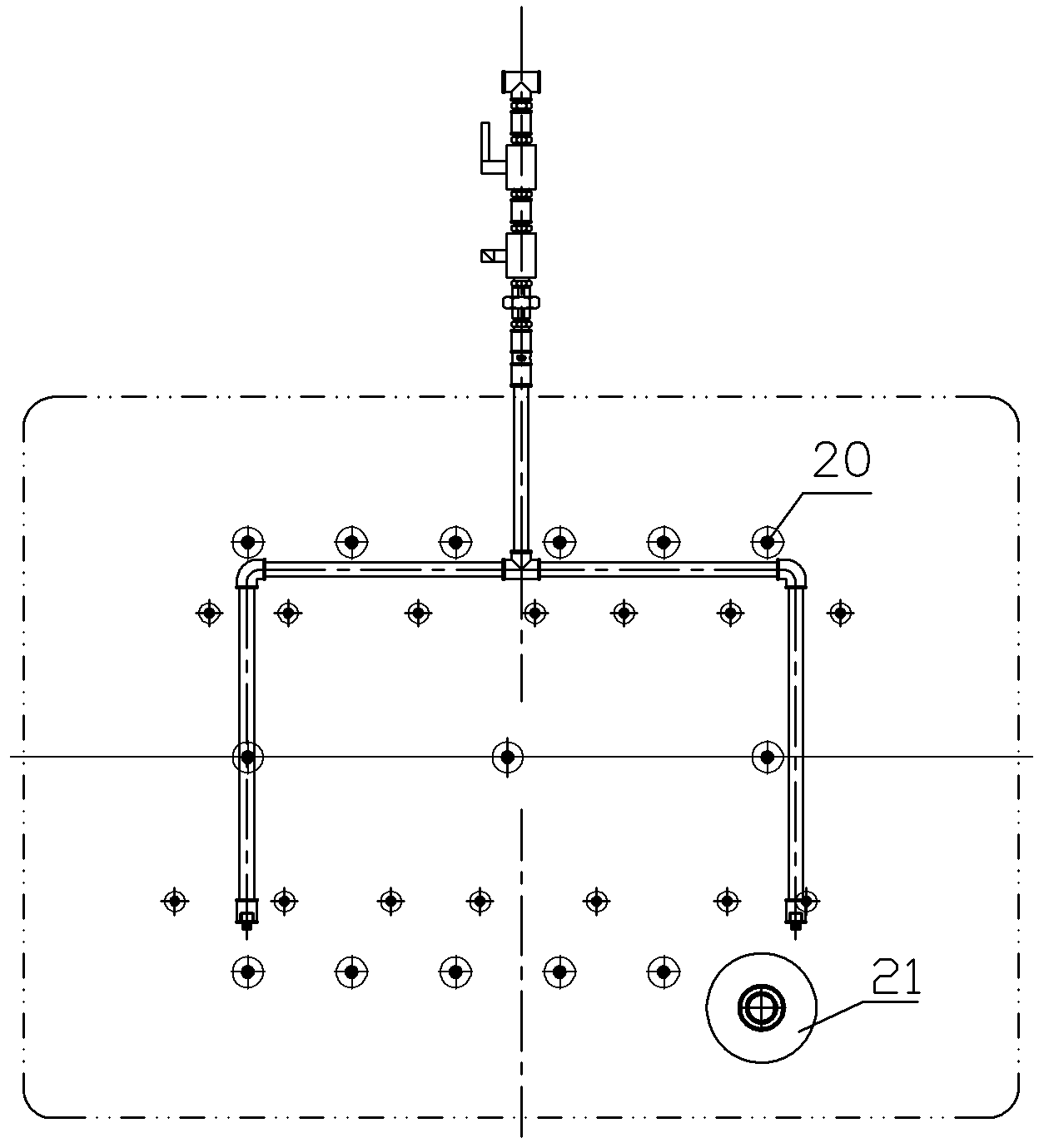

[0027] refer to Figure 8 , the burner 2 includes a natural gas inlet 16, an air inlet 17, and a mixed natural gas outlet 18 that com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com