Automobile frame longitudinal beam detection and precise positioning device and detection method

An automobile frame, precise positioning technology, applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., to achieve precise positioning, ensure detection quality and detection speed, and have broad product market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

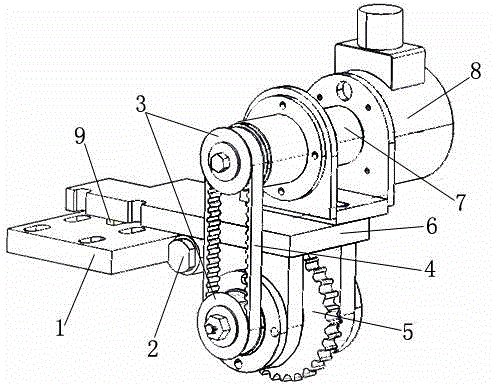

[0021] The connection plate 1 is connected with the motion platform of the CNC punch press to ensure that the device moves together with the longitudinal beam; the large synchronous pulley 5 is in contact with the timing belt 4 on the stationary platform of the CNC punch press to ensure that the device can collect when the longitudinal beam moves. The movement information of the longitudinal beam (the number of pulses of the encoder), the rotation information of the large synchronous pulley 5 pass through two small synchronous pulleys 3 and the synchronous belt 4, and the coupling 7 is connected with the encoder 8, so that the linear motion The information is converted into the number of pulses of the encoder 8, so as to obtain real-time information on the movement of the longitudinal beam for image acquisition of the longitudinal beam. During the movement of the longitudinal beam, the stationary platform on the CNC punching machine is not absolutely flat, and there are many un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com