Piezoelectric ceramic ultrasonic atomizing sheet

A technology of ultrasonic atomizing sheet and piezoelectric ceramic sheet is applied in the field of atomizing sheet, which can solve the problems of low energy conversion efficiency in radial drive mode, easy blockage of micropores, and high processing difficulty, so as to widen the scope of atomization effect and not easy to The effect of falling off and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

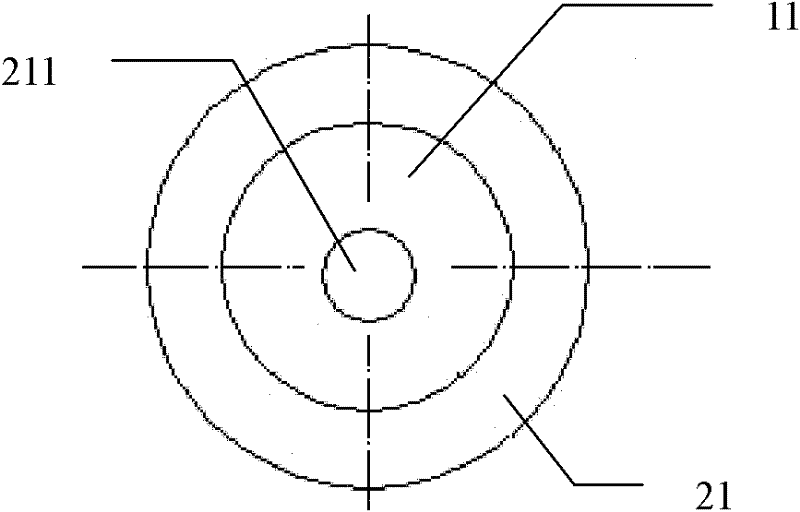

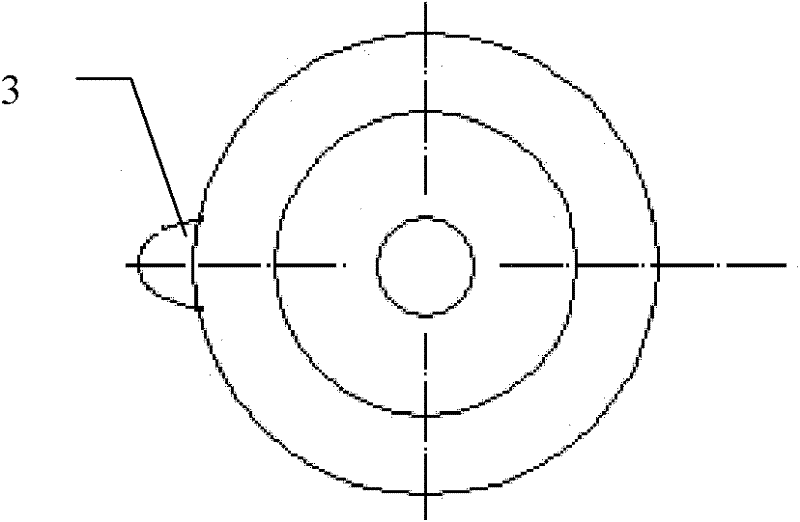

[0042] Such as figure 1 , figure 2 , image 3 As shown, the piezoelectric ceramic ultrasonic atomizing sheet of the present embodiment includes a set of three piezoelectric ceramic sheets, that is, the first piezoelectric ceramic sheet 11, the second piezoelectric ceramic sheet 12, and the third piezoelectric ceramic sheet 13. The piezoelectric ceramic sheet group 1 and a group of metal sheet groups 2 composed of 2 metal sheets, that is, the first metal sheet 21 and the second metal sheet surface 22; in the piezoelectric ceramic sheet group 1, the first piezoelectric ceramic The sheet is provided with a first through hole 14, the second piezoelectric ceramic sheet is provided with a second through hole 14', and the third piezoelectric ceramic sheet is provided with a third through hole 14''; the piezoelectric ceramic sheet and the metal sheet Interspersed with each other, that is, according to the order from the top to the first piezoelectric ceramic sheet 11, the first me...

Embodiment 2

[0050] like Figure 4 As shown, the piezoelectric ceramic ultrasonic atomizing sheet of the present embodiment includes a group of three piezoelectric ceramic sheets, that is, a first piezoelectric ceramic sheet 41, a second piezoelectric ceramic sheet 42, and a third piezoelectric ceramic sheet 43. A piezoelectric ceramic sheet group and a group of metal sheet groups composed of 2 metal sheets, that is, the first metal sheet 51 and the second metal sheet surface 52; the first piezoelectric ceramic sheet is provided with a first through hole 411, and the second piezoelectric ceramic sheet The sheet is provided with a second through hole 421, and the third piezoelectric ceramic sheet is provided with a third through hole 431; the piezoelectric ceramic sheet and the metal sheet are stacked on each other, that is to say, from the top to the first piezoelectric ceramic sheet sheet 41, the first metal sheet 51, the second piezoelectric ceramic sheet 42, the second metal sheet 52, a...

Embodiment 3

[0057] like Figure 9 As shown, another embodiment of the present invention is provided, which adopts a structure similar to Embodiment 1 and Implementation 2, and also uses three piezoelectric ceramic sheets and two metal sheets, and each piezoelectric ceramic sheet and each metal sheet are connected to each other. Arranged in a staggered order. Among them, the first metal sheet 8 is provided with a large number of first atomization holes 81, which cover the piezoceramic through-holes in a flat shape; the second metal sheet 9 is provided with a large number of second atomization holes 91, which cover the piezoceramic through-holes. The portion of the hole has a convex cap shape. This embodiment can realize the mutual coupling of bending vibration and axial vibration of the metal sheet, overcome the defect that the existing atomizing sheet can only vibrate in one direction, and achieve a better atomizing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com