Regeneration method of powdered activated carbon

A technology of powdered activated carbon and activated carbon, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve problems such as unsatisfactory effects, achieve regeneration and resource utilization, avoid carbon dioxide emissions, and capture high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

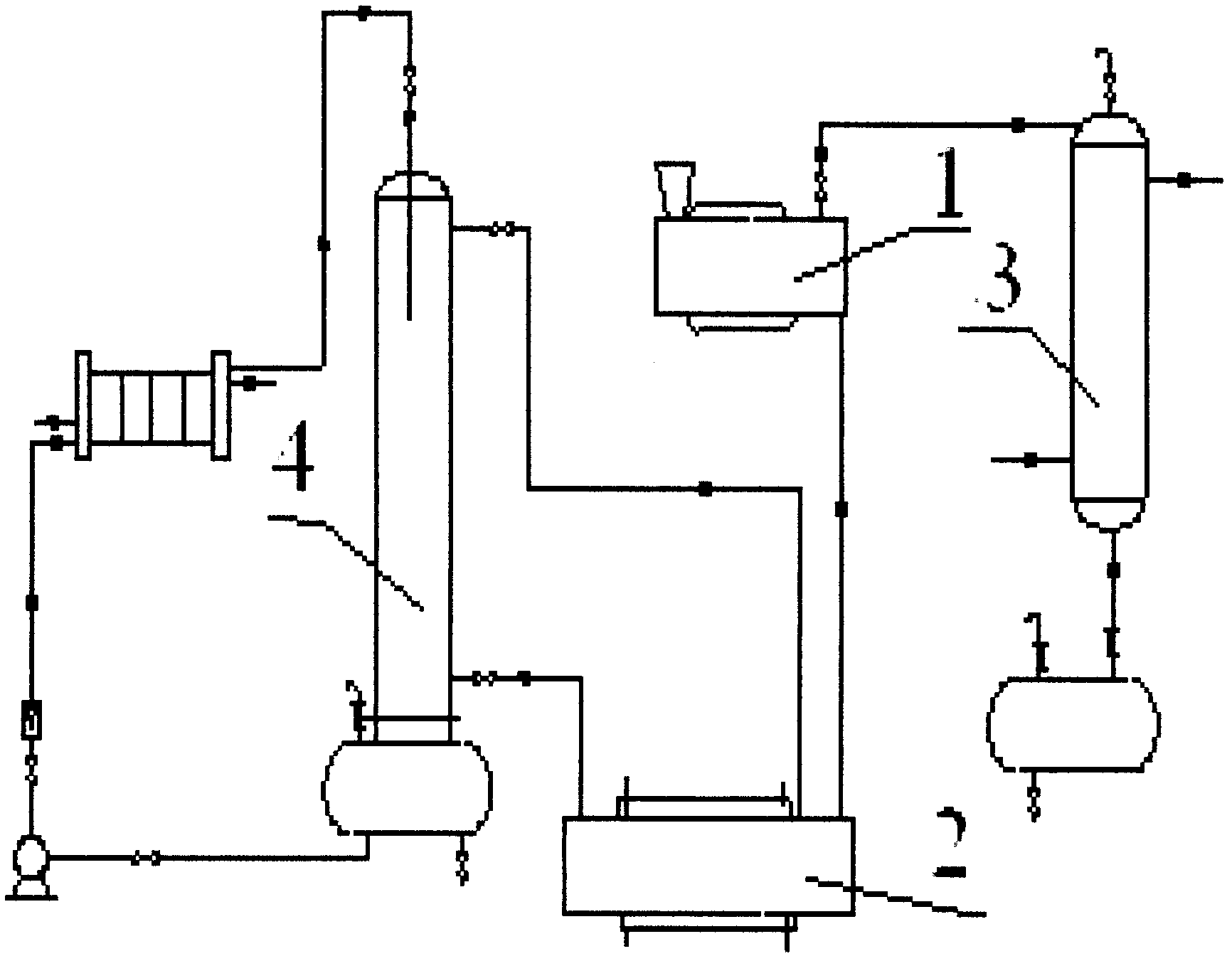

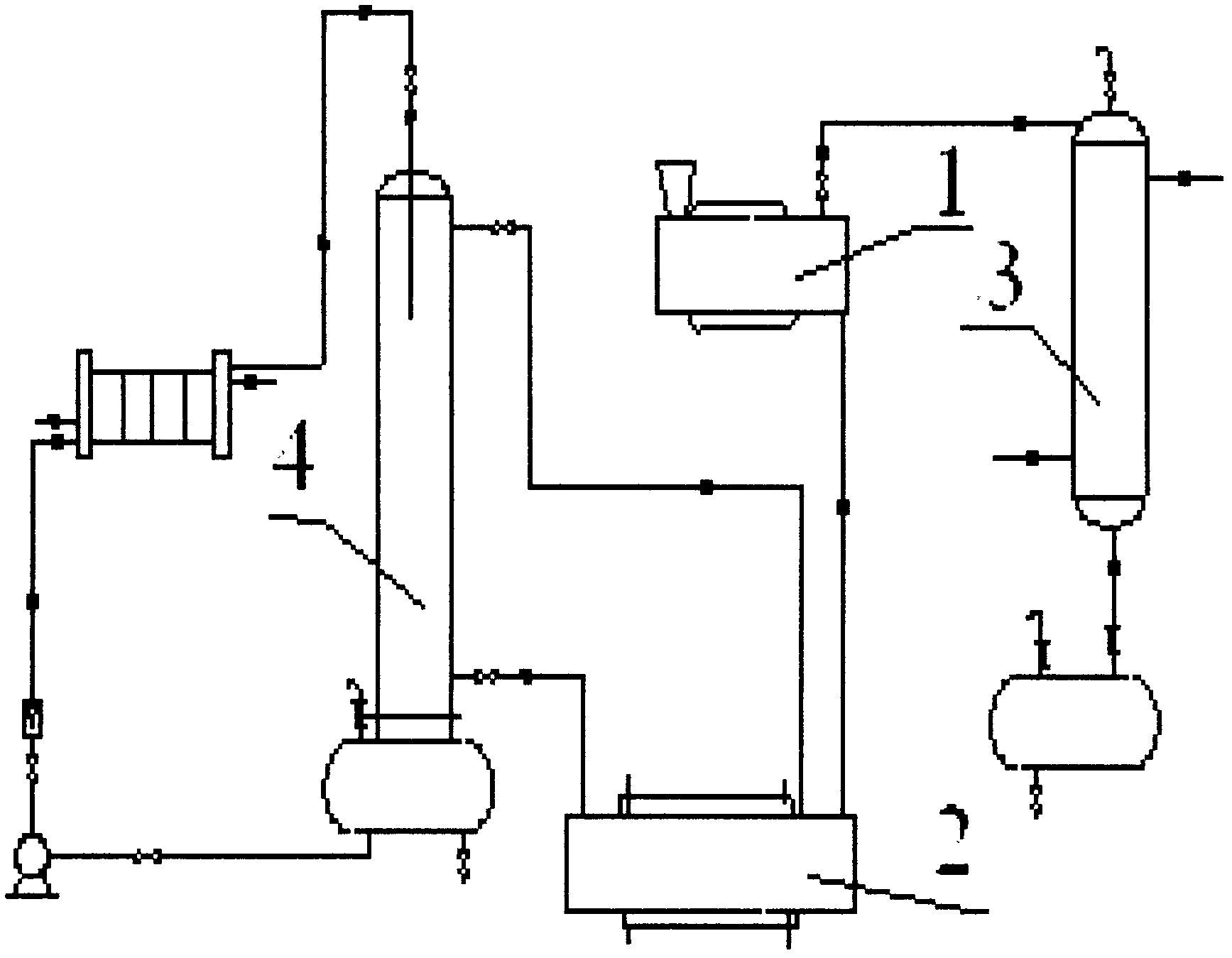

Image

Examples

Embodiment 1

[0021] When the temperature in the primary regeneration furnace rises to 100°C and the temperature in the secondary regeneration furnace rises to 400°C, add caffeine-loaded activated carbon into the primary regeneration furnace at a rate of 0.9t / h. When the water content of the activated carbon drops to 8%, the dehydrated activated carbon is pushed into the secondary regeneration furnace, and the nitrogen gas velocity is 0.007m / s. At this stage, the caffeine is sublimated and the pigment is decomposed. The sublimated caffeine enters the spray tower for capture and recovery, the recovery rate of caffeine is 98%, and the regeneration rate of activated carbon is 88%.

Embodiment 2

[0023] When the temperature in the primary regeneration furnace rises to 100°C and the temperature in the secondary regeneration furnace rises to 400°C, add caffeine-loaded activated carbon into the primary regeneration furnace at a rate of 0.6t / h. When the water content of the activated carbon drops to 6%, the dehydrated activated carbon is pushed into the secondary regeneration furnace, and the nitrogen gas velocity is 0.006m / s. At this stage, the caffeine is sublimated and the pigment is decomposed. The sublimated caffeine enters the spray tower for capture and recovery, the recovery rate of caffeine is 98.5%, and the regeneration rate of activated carbon is 89%.

Embodiment 3

[0025] When the temperature in the primary regeneration furnace rises to 105°C and the temperature in the secondary regeneration furnace rises to 420°C, add caffeine-loaded activated carbon into the primary regeneration furnace at a rate of 0.5t / h. When the water content of the activated carbon drops to 5%, the dehydrated activated carbon is pushed into the secondary regeneration furnace, and the nitrogen gas velocity is 0.005m / s. At this stage, the caffeine is sublimated and the pigment is decomposed. The sublimated caffeine enters the spray tower for capture and recovery, the recovery rate of caffeine is 98%, and the regeneration rate of activated carbon is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com