Inorganic/organic composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane, organic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uneven dispersion, unstable membrane performance, etc. The effect of good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

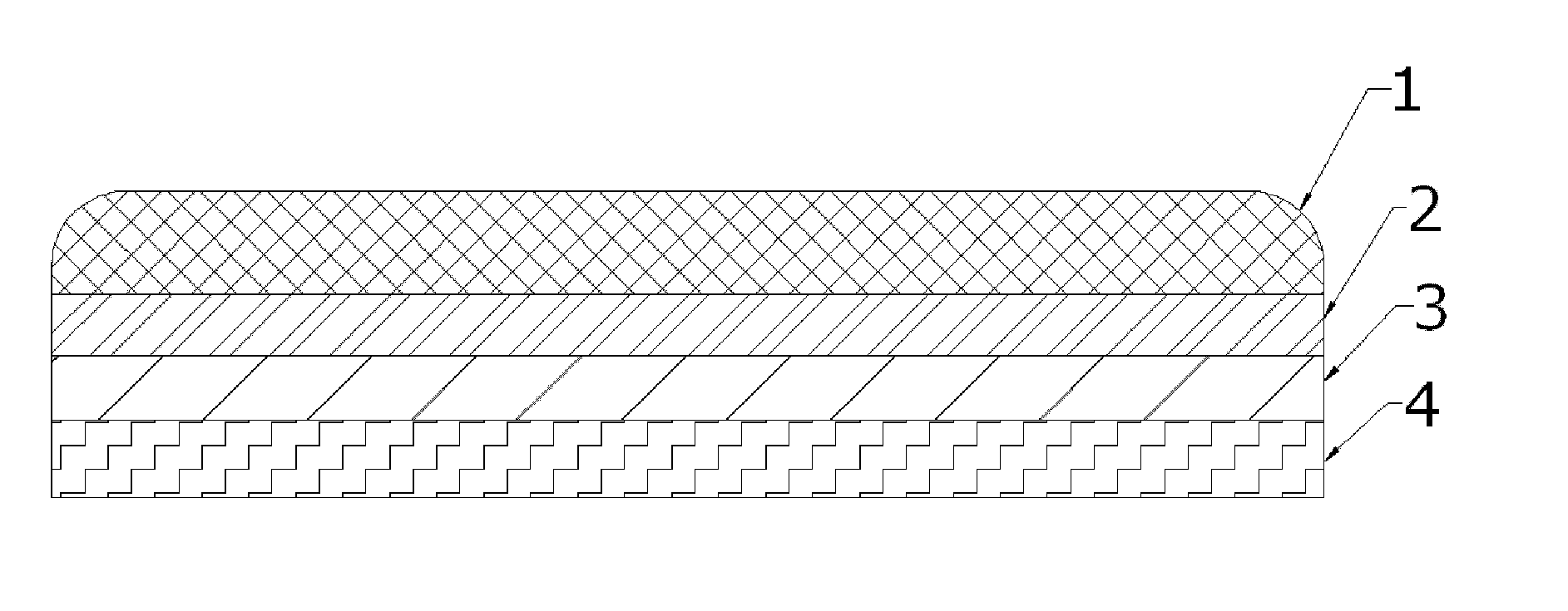

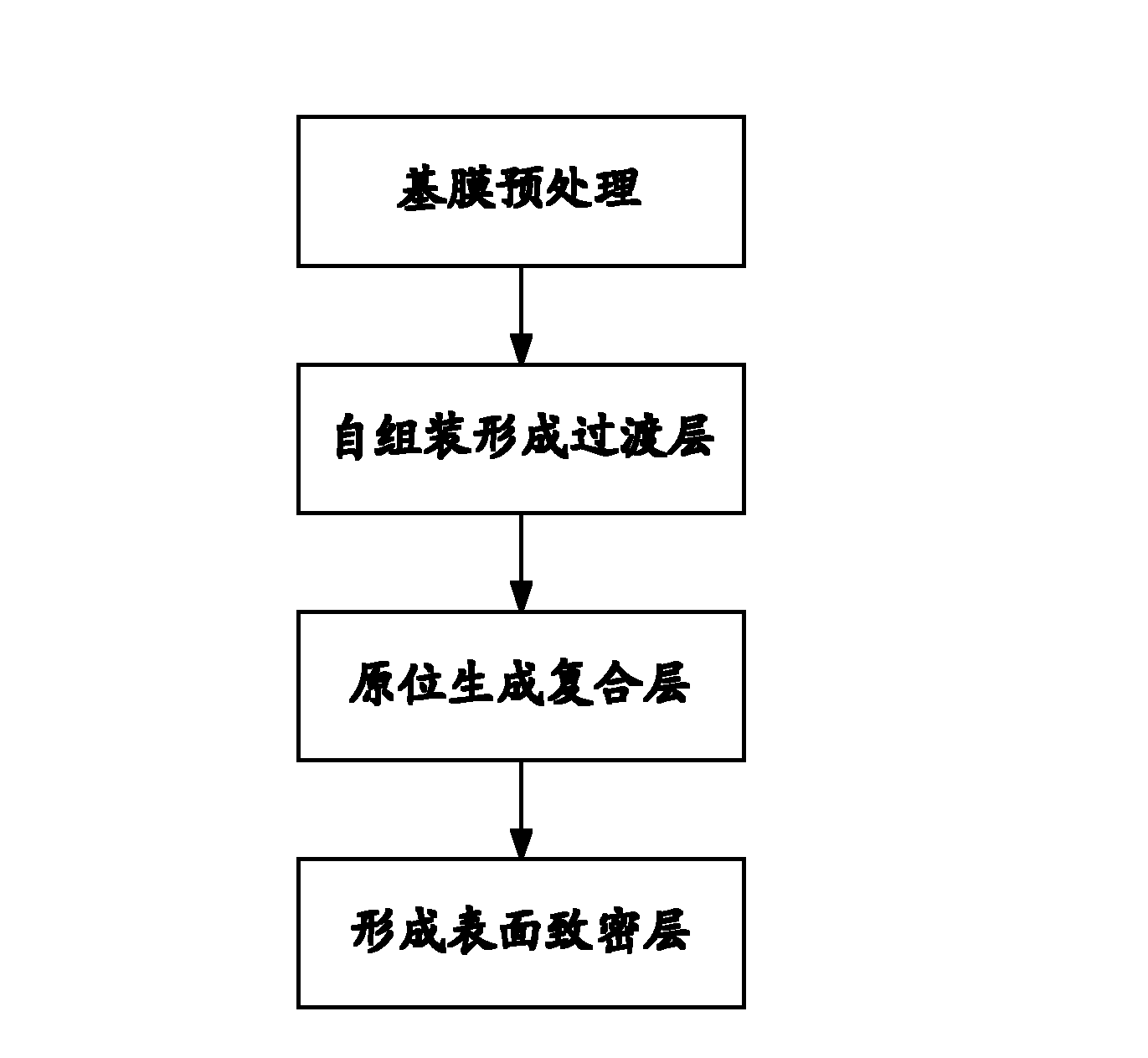

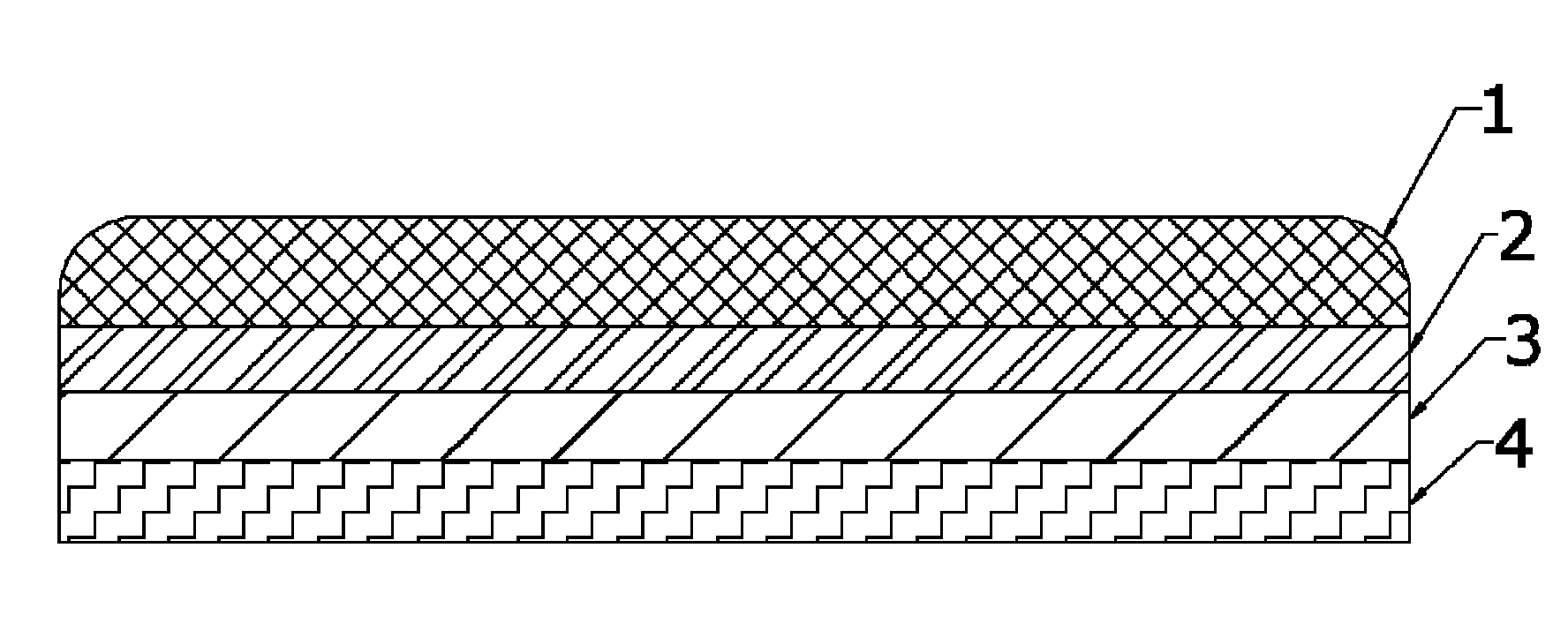

[0023] The preparation method of the above inorganic / organic composite nanofiltration membrane, such as figure 2 As shown, the following steps are included: 1) base film pretreatment; 2) self-assembly to form a transition layer; 3) in-situ generation of a composite layer; 4) formation of a surface dense layer.

[0024] It is achieved through the following specific schemes:

[0025] 1) Pretreatment of the base membrane: Take the ultrafiltration membrane as the base membrane, treat the base membrane with 0.5-4.0 mol / L sodium hydroxide solution for 30-60 minutes, and then wash with deionized water to neutrality.

[0026] 2) Self-assembled polyelectrolyte composite membrane transition layer on the base membrane: immerse the base membrane treated in step (1) in a cationic polyelectrolyte solution of 1.0-8.0g / L, immerse it for 10-30 minutes, and then take it out with deionized water Wash thoroughly; then transfer to 1.0-8.0g / L anionic polyelectrolyte solution, make cationic polyelectroly...

Embodiment 1

[0031] 1) Pretreatment of the base membrane: Take the polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of less than 100,000 as the base membrane, treat the base membrane with 0.5 mol / L sodium hydroxide solution for 60 minutes, and then wash it with deionized water to the middle Sex.

[0032] 2) Self-assembly on the base membrane to form the transition layer of the polyelectrolyte composite membrane: the base membrane treated in step (1) is immersed in a 1.0g / L polyethyleneimine (PEI) cationic polyelectrolyte solution, and after immersing for 30 minutes, take it out for use Rinse thoroughly with deionized water; then transfer to 1.0g / L polystyrene sodium sulfonate (PSS) anionic polyelectrolyte solution, so that the cationic polyelectrolyte and anionic polyelectrolyte will form a polyelectrolyte composite layer through electrostatic action, and then rinse thoroughly , Blow dry with high purity nitrogen;

[0033] 3) In-situ generation of inorganic nanopartic...

Embodiment 2

[0037] 1) Pretreatment of base membrane: Take polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of less than 100,000 as the base membrane, treat the base membrane with a 4.0 mol / L sodium hydroxide solution for 30 minutes, and then wash it with deionized water to the middle Sex.

[0038] 2) Self-assembly on the base membrane to form the transition layer of the polyelectrolyte composite membrane: the base membrane treated in step (1) is immersed in a 8.0g / L polyethyleneimine (PEI) cationic polyelectrolyte solution, and then immersed for 10 minutes. Rinse thoroughly with deionized water; then transfer to 8.0g / L polystyrene sodium sulfonate (PSS) anionic polyelectrolyte solution, so that the cationic polyelectrolyte and anionic polyelectrolyte will form a polyelectrolyte composite layer through electrostatic action, and then rinse thoroughly , Blow dry with high purity nitrogen;

[0039] 3) In-situ generation of inorganic nanoparticles-polyelectrolyte composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com