Pressing drive system of juicer for fruits and vegetables

A drive system and juice extractor technology, which is applied in juice extraction, mechanical equipment, transmission devices, etc., can solve problems such as drive failure, strong contact pressure, and large lateral component force, and achieve increased action frequency, improved production efficiency, and smooth motion. Smooth and powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

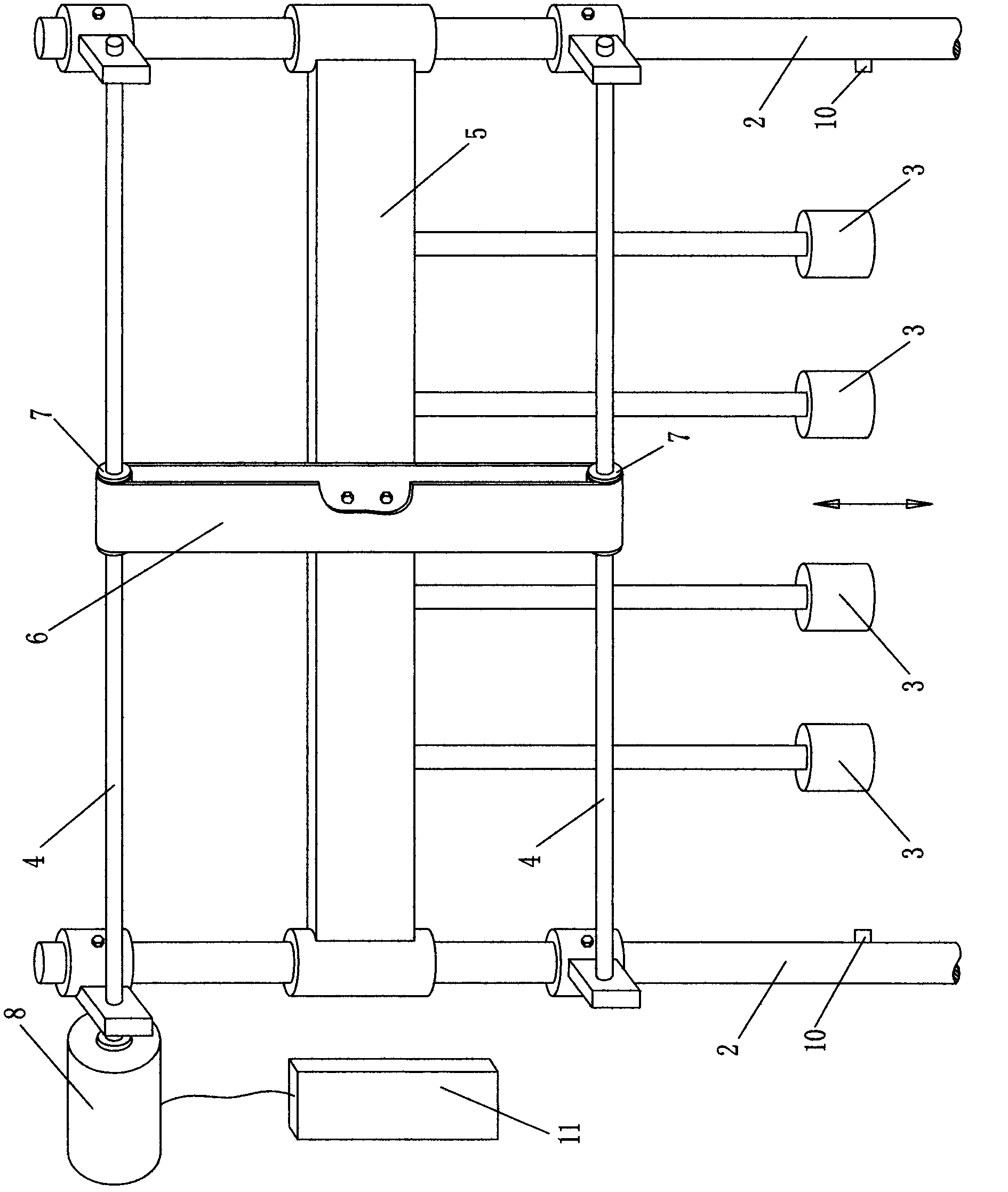

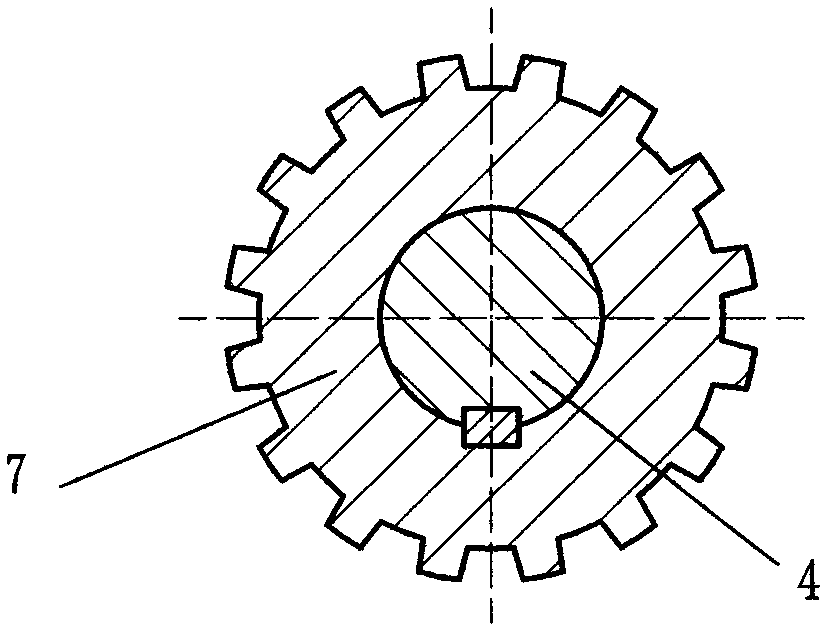

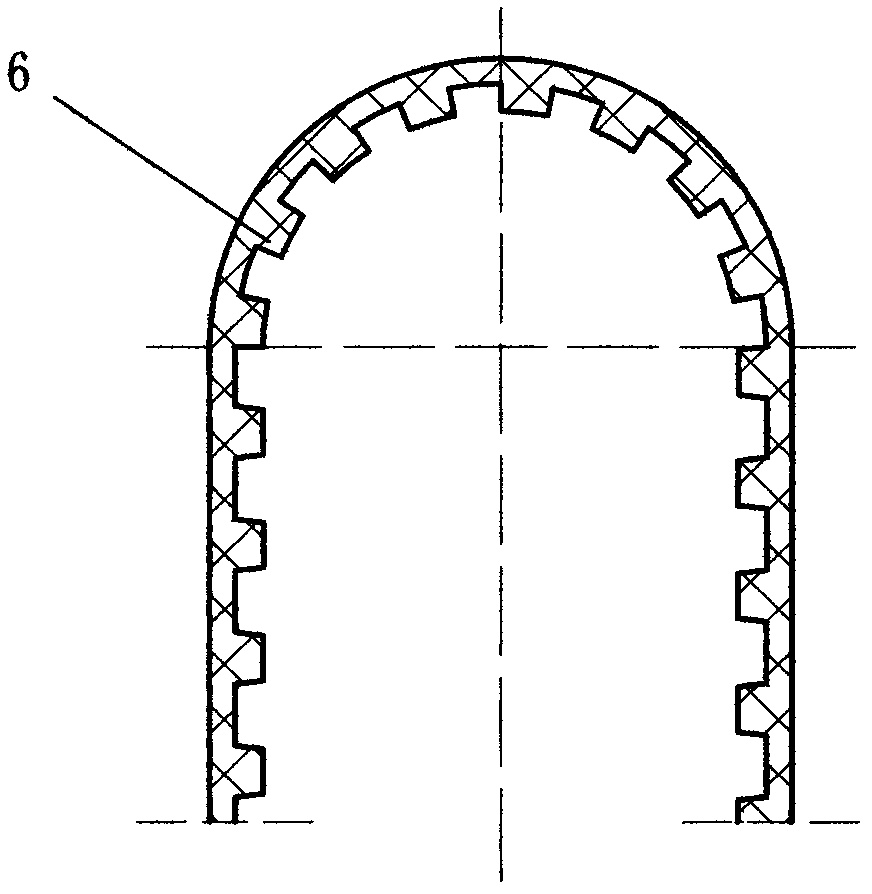

[0015] A specific implementation of the drive system of the present invention is as attached figure 1 , 2 , 3, the system has a squeezing beam 5 connected to the juicer mechanism 3 to reciprocate on the column 2 of the juicer by a sliding sleeve, and the axes are set in the belt circle of the full-circle synchronous belt 6 with internal cross teeth to be parallel to each other There is a synchronous pulley 7 with external teeth meshing with the synchronous belt teeth, and its shaft 4 is installed separately so that the synchronous pulley tensions the synchronous belt into a long straight strip parallel to the column, and the pressing beam is connected to the long straight part of the synchronous belt , one of the synchronous pulleys is driven by a stepper motor 8, and the other synchronous pulley is driven, the stepper motor is connected to the controller 11, and the photoelectric sensor 10 for detecting the position of the juice extractor is arranged on the juice extractor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com